Products

Material Receiving and Powder Feeding Process

Achieved Speedy and efficient reception and supply of materials

Achieved Speedy and efficient reception and supply of materials

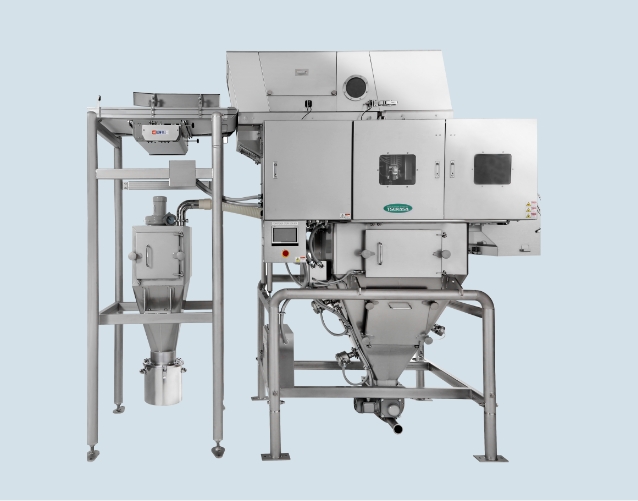

Automatic bag opening System

Automatic bag opening System

A system equipped with functions for bag supply, surface cleaning, and bag openingMORE >

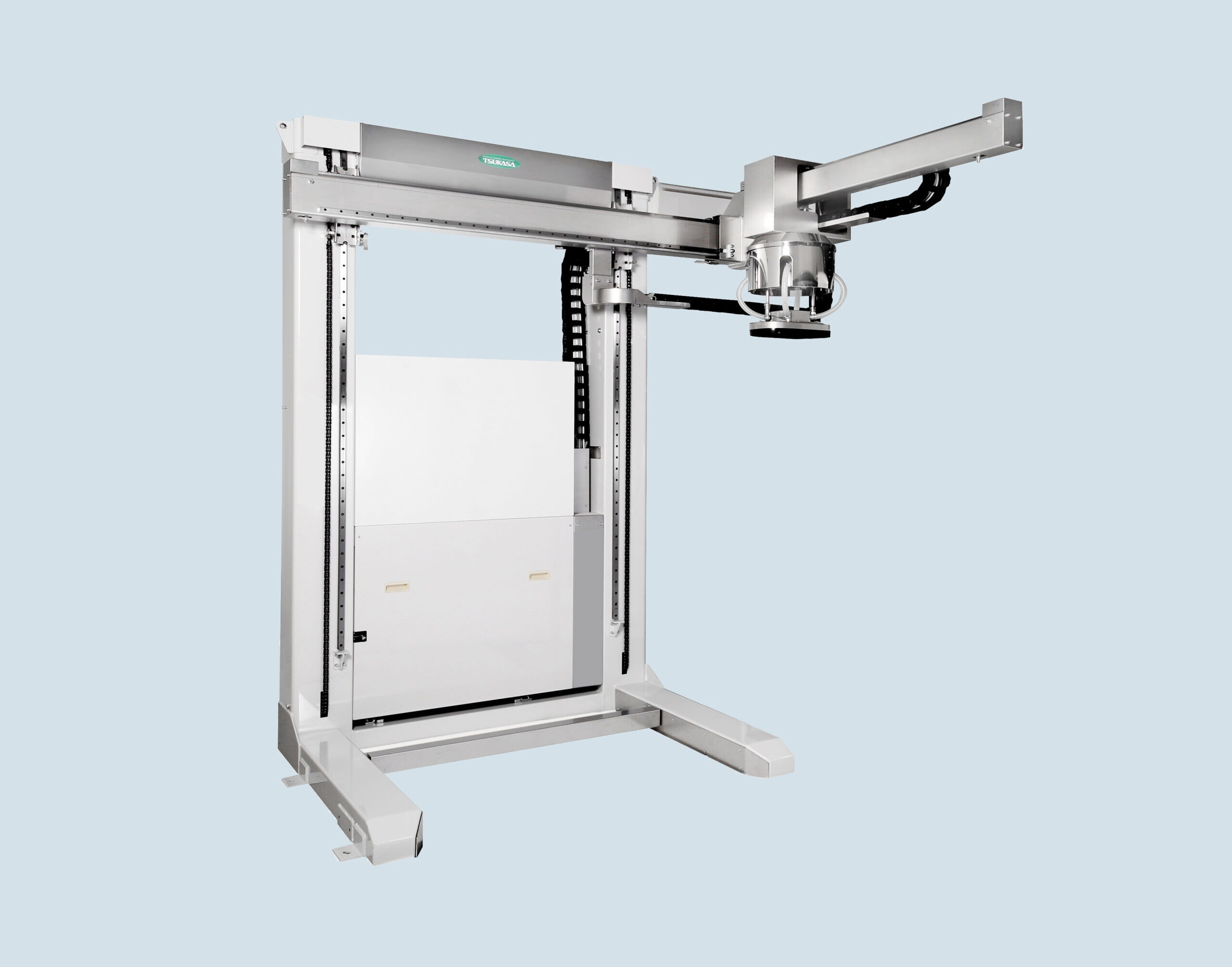

Depalletizer robo(DPL)

An automated conveyor system equipped with a special suction mechanism and Cartesian coordinate drive for fast bag supply.MORE >

PowOpener(PO)

Compact automatic bag-opening equipment you can place anywhereMORE >

PowOpener Disassembly Washing Type(PO-WR)

An automatic bag opener designed for frequent cleaning during raw material switchingMORE >

Pow Breaker(Solidified powder crusher)

A solidified powder crusher that eliminates bag opening problems with automatic bag openersMORE >

Raw material receiving equipment for flexible containers

FleconOpener Stock Model(FO-TF)

Bag-opening equipment for flexible container bags which can deal with powder that easily scattersMORE >

FleconOpener Compact Hopper Model(FO-SH)

A raw material receiving equipment for flexible containers, compatible with granular materials such as granulated sugar and refined salt.MORE >

Manual in-feed equipment

Dumping Server Conical Model(DSV-CF-300)

For this manual in-feed equipment, we painstakingly designed the height of the in-feed port, and reduced the burden on material feedingMORE >

Dumping Server and LINESIFTER Integrated Model(DSV-LS-25/50-300)

Manual in-feed equipment that is capable of simultaneously removing foreign materials and breaking down clumps in raw materials.MORE >

Dumping Server and LINESIFTER Integrated Model Hopper Type(DSV-LS-25/50-HP)

Manual in-feed equipment that is capable of simultaneously removing foreign materials and breaking down clumps in raw materials.MORE >

Dumping Server Premixing Model(DSV-PM)

A manual in-feed unit featuring a unique mixing paddle design that enables premixing of raw materialsMORE >

Dumping Server Hopper Model(DSV-S)

Manual in-feed equipment that is compact and can be installed in a limited spaceMORE >

Weighing Process

Precisely weight large amount of main materials and small amount of additives

Precisely weight large amount of main materials and small amount of additives

Weighing equipment

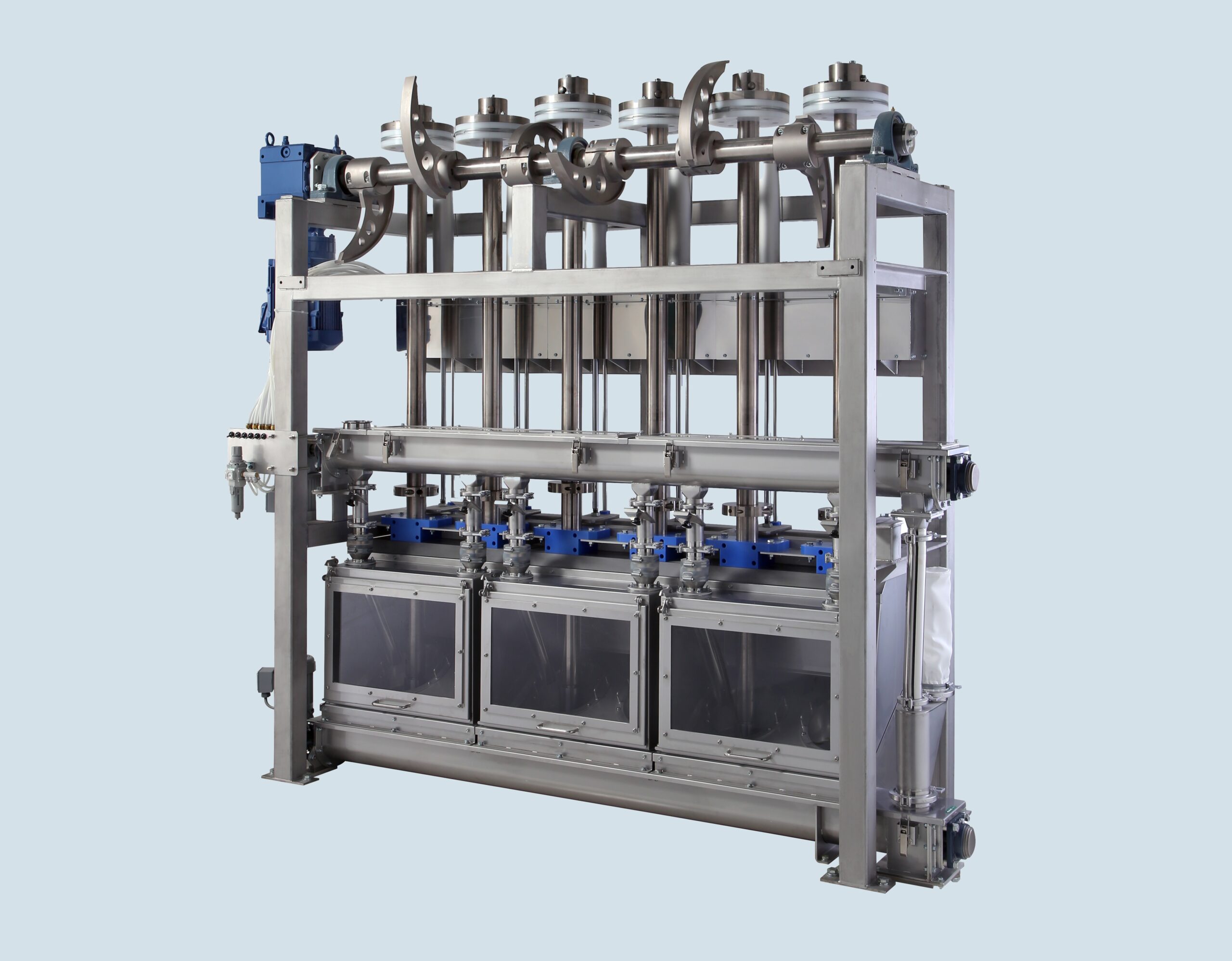

Divider Scale Terminal Fixed Model(DSC-TDP-5-FX)

Automatic dividing and weighing equipment that can handle multiple raw materials using a stocker-fixed modelMORE >

Divider Scale Terminal Detachable Model(DSC-TDP-4-DE)

Automatic dividing and weighing equipment that can handle multiple raw materials using a stocker detachable modelMORE >

Divider Scale Simple(DSC-S)

Automatic dividing/weighing equipment ideal for portioning and weighing secondary materials and additives.MORE >

Divider Scale Combination(DSC-C)

Automatic dividing/weighing equipment which can automatically weigh a wide variety of materialsMORE >

Divider Scale Hybrid 200L(DSC-HV-200)

A weighing machine that achieves compactness through multi-function integration, dramatically enhancing factory space utilizationMORE >

Divider Scale Hybrid 50L(DSC-HV-50)

A manual-feed weighing machine that allows hand-loading of raw materials and portions stocked materials into smaller quantitiesMORE >

Divider Scale Receiver Model(DSC-RC)

Multi-function unit capable of automatically weighing raw materials transported via pneumatic conveyanceMORE >

Divider Scale Equipment-mounted Model(DSC-EM)

Weighing equipment attachable to the discharge port of a silo or mixerMORE >

PowScale Hopper Model(PS-HP)

Hopper model weighing equipment with a simple and efficient designMORE >

Divider Scale Mobile Robot

Integrating a weighing function into the AMR enables full automation from weighing to transportMORE >

Divider Scale Hybrid/CE Model

An automatic weighing unit certified with the CE mark, compliant with EU safety standardsMORE >

Storage Process

We propose optimal stock and discharge methods depending on the material and process

We propose optimal stock and discharge methods depending on the material and process

Storage tank equipment

PowSilo(PSL)

Compatible with a wide range of operating conditions—from small indoor tanks to large outdoor silosMORE >

PowSilo Fabric Model(PSL-FB)

High safety fabric silo that conforms to the positive list of the Food Sanitation ActMORE >

Discharge equipment

Dust Collecting Process

Achieved high efficiency in dust collection and space-saving

Achieved high efficiency in dust collection and space-saving

Dust Collector

PowFilter Built-in Model(F)

Dust collectors which can be incorporated directly into equipment including tanksMORE >

PowFilter Compact Model(FS)

Usable for a wide variety of uses as a general-purpose small dust collectorMORE >

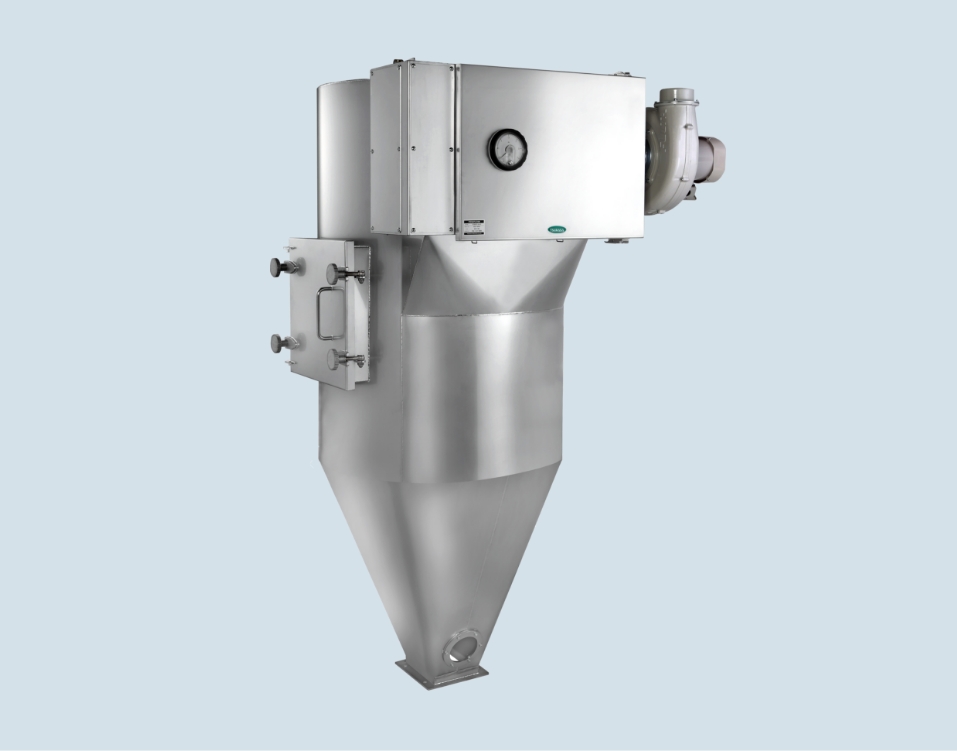

PowFilter Receiver Model(FRH)

Dust collector used as a receiver from pneumatic conveyanceMORE >

PowFilter Central Cleaner Type

Can collect dust on several floors through piping from the main dust collectorMORE >

Mixing Process

Quick mixing is possible with the special shape unique to TSUKASA

Quick mixing is possible with the special shape unique to TSUKASA

Mixer

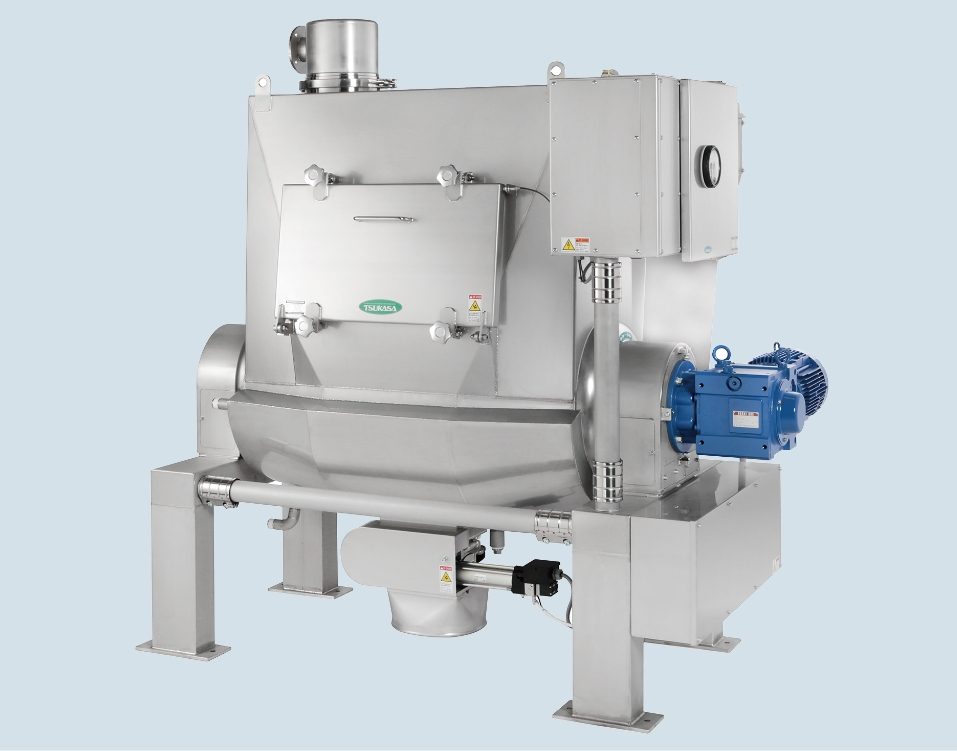

PowMixer Conical & Horizontal Model(PM-CH)

A horizontal mixer with a unique paddle design enables high-efficiency, high-precision mixing in short cyclesMORE >

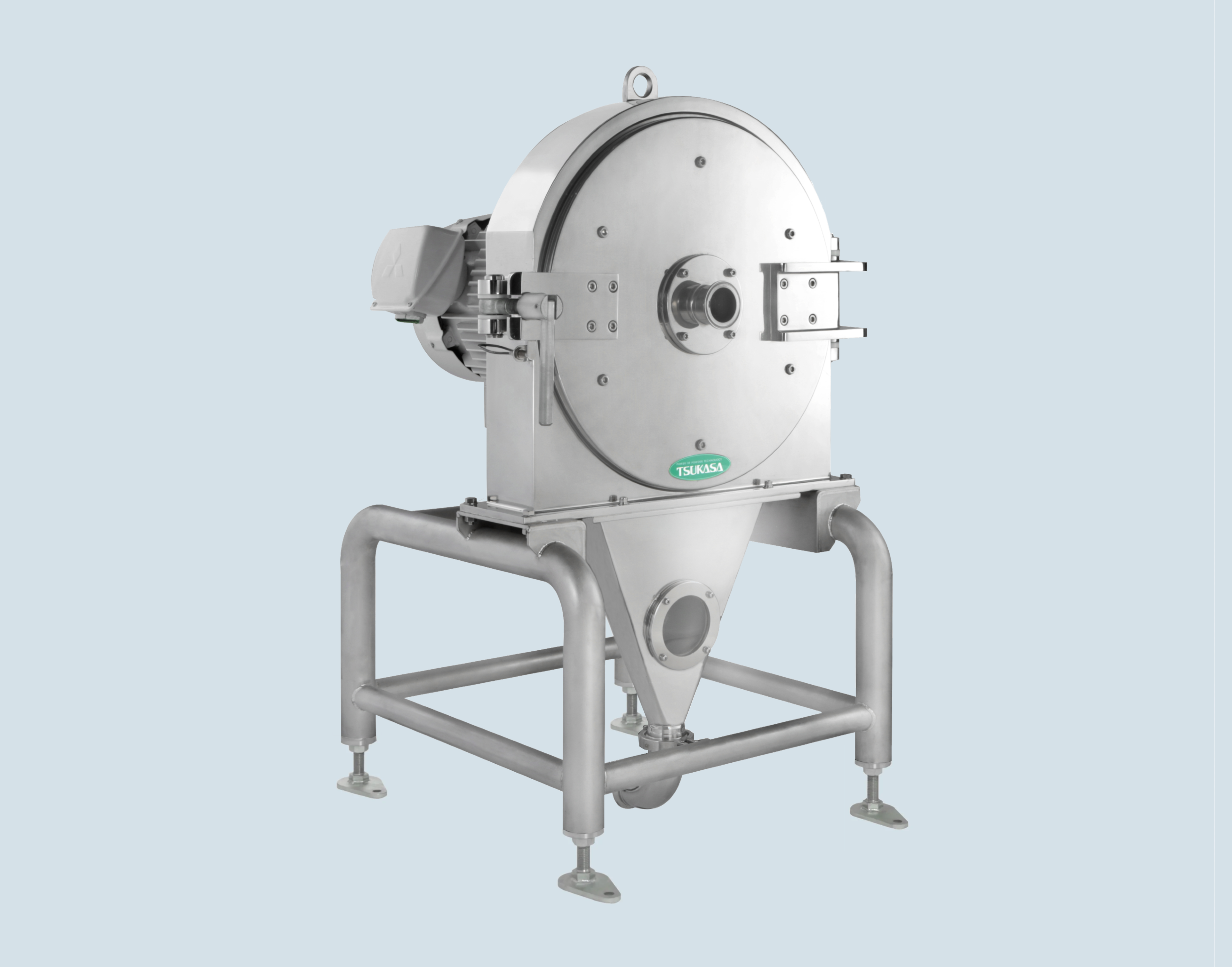

PowMixer Conical & Vertical Model(PM-CV)

A vertical mixer equipped with original spiral blades for high-precision mixing in a short time, with excellent cleanabilityMORE >

PowMixer Cross-rotary Model(PM-CM)

Mixer with for dispersion and uniform mixing of small and very small quantitiesMORE >

PowMixer Cross-rotary Model Laboratory Specifications(CM-3)

Small cross rotary mixer suitable for experiments and researchMORE >

Batter Mixer (BT)

Batter manufacturing mixer for mixing powder in liquidMORE >

Sifting and Foreign-material Removal Process

Performs efficient sieving and foreign material removal

Performs efficient sieving and foreign material removal

Sifter

LINESIFTER®︎ Standard Model(LS)

In-line model sifter installed in the pneumatic conveyance lineMORE >

LINESIFTER®︎︎ Two sized classify Model(LS-SP)

Sifter in the pneumatic conveyance line with the ability to classify materials into two particle sizeMORE >

PowSifter Standard Model(PSF)

In-line model sifter which is installed in chute conveyance linesMORE >

PowSifter︎ Two sized classify Model(PSF-SP)

Sifter which is installed in the chute conveyance line for classifying materials into two particle sizeMORE >

PowSifter︎ Three sized classify Model(PSF-SPW)

In-line model sifter which is installed in the chute conveyance line for classifying materials into three particle sizeMORE >

PowSifter Special Specification Example(PSF-25/70-Z)

Easiness to clean and visibility of the inside of the equipment improved by adding a side inspection port.MORE >

PowSifter Special Specification Example(PSF-15/25 GMP)

Specially designed for R&D and prototyping of pharmaceuticals and multi-ingredient applicationsMORE >

Sieve Cleaner for LINESIFTER® and PowSifter

Cleaning equipment that can clean without contaminating the surroundingsMORE >

Foreign material removal equipment

Magcap(MCP)

Magnetic foreign matter removal device which can be installed at the inspection port of chute conveyance pipesMORE >

Magcap Removable Types(MC)

Magnetic foreign matter removal device with a detachable magnet barMORE >

Magnet Spout(MS-G)

Magnetic foreign matter removal device which can be installed in chute conveyance pipesMORE >

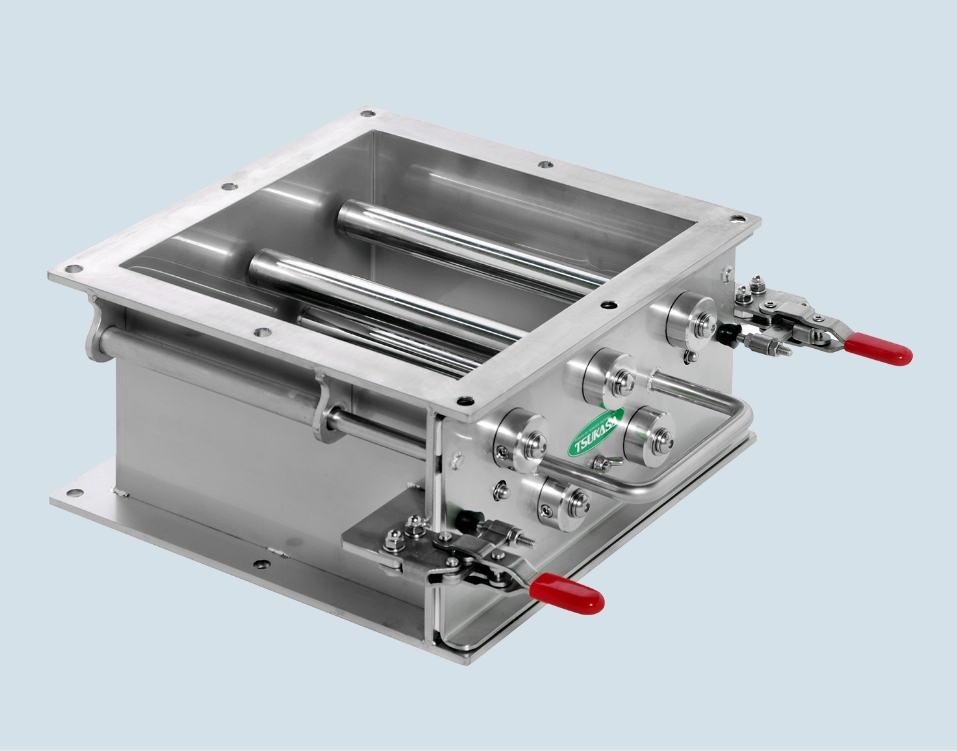

PowMagnet Gate Model(MG2)

Magnetic foreign matter removal device which can be installed at the feed/discharge port of equipment and tanksMORE >

PowMagnet Rotary Model(SRM2)

Magnetic foreign matter removal device which can deal with highly adhesive powderMORE >

PowMagnet Inline Model(NIM)

Magnetic foreign matter removal device which can be installed in the pneumatic conveyance line, etc.MORE >

PowMagnet Inline Model Bar Type(NIMB)

Magnetic foreign matter removal device with the detachable cap structureMORE >

Crushing and Milling Process

We propose equipment optimal for purposes and materials

We propose equipment optimal for purposes and materials

Crushing equipment

PowCutter(PCT)

A crusher capable of roughly crushing a wide range of materials such as bread, biscuits, and piesMORE >

PowCutter LAB

A compact crusher that can be used on a tableMORE >

PowCrusher(PCR)

Crusher for crushing powder clumps and snackMORE >

Mill

Line Mill®︎(LM)

A pin mill-type grinder installable in pneumatic transport linesMORE >

PowJet(PJ)

Dry fine pulverizer utilizing gas-fluid energyMORE >

Wave Mill(WM)

Airflow grinder with a proprietary grinding mechanismMORE >

Stamp Mill

A pulverizer that replicates the traditional “mortar and pestle” mechanismMORE >

Drying and Controlling Temperature Process

Drying and temperature adjustment for stable quality throughout the year

Drying and temperature adjustment for stable quality throughout the year

Powder temperature adjustment equipment

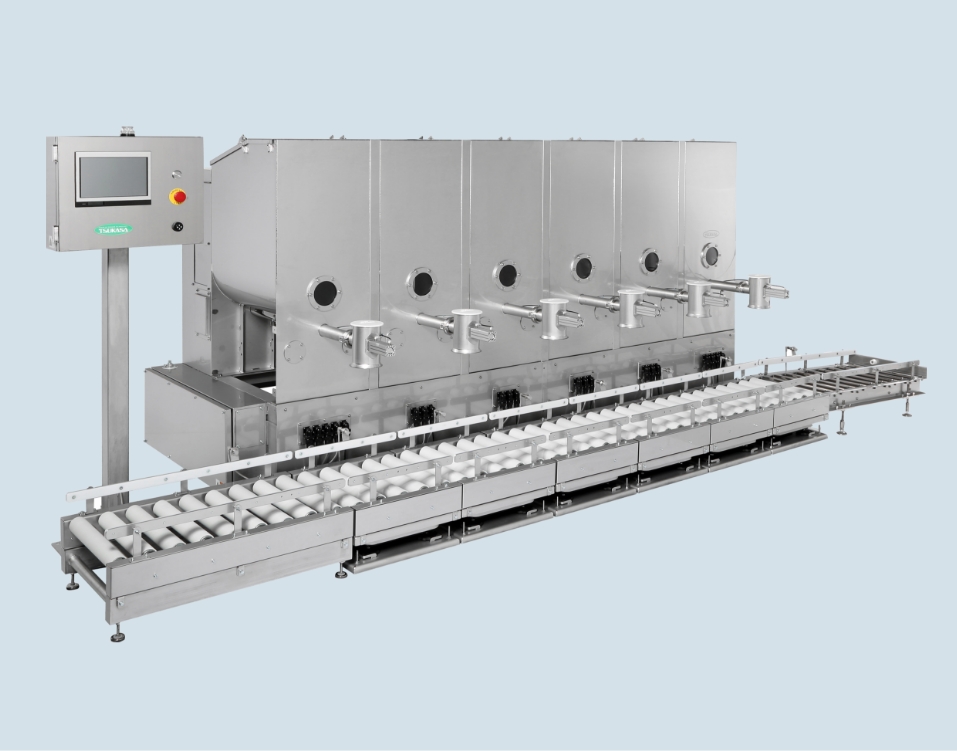

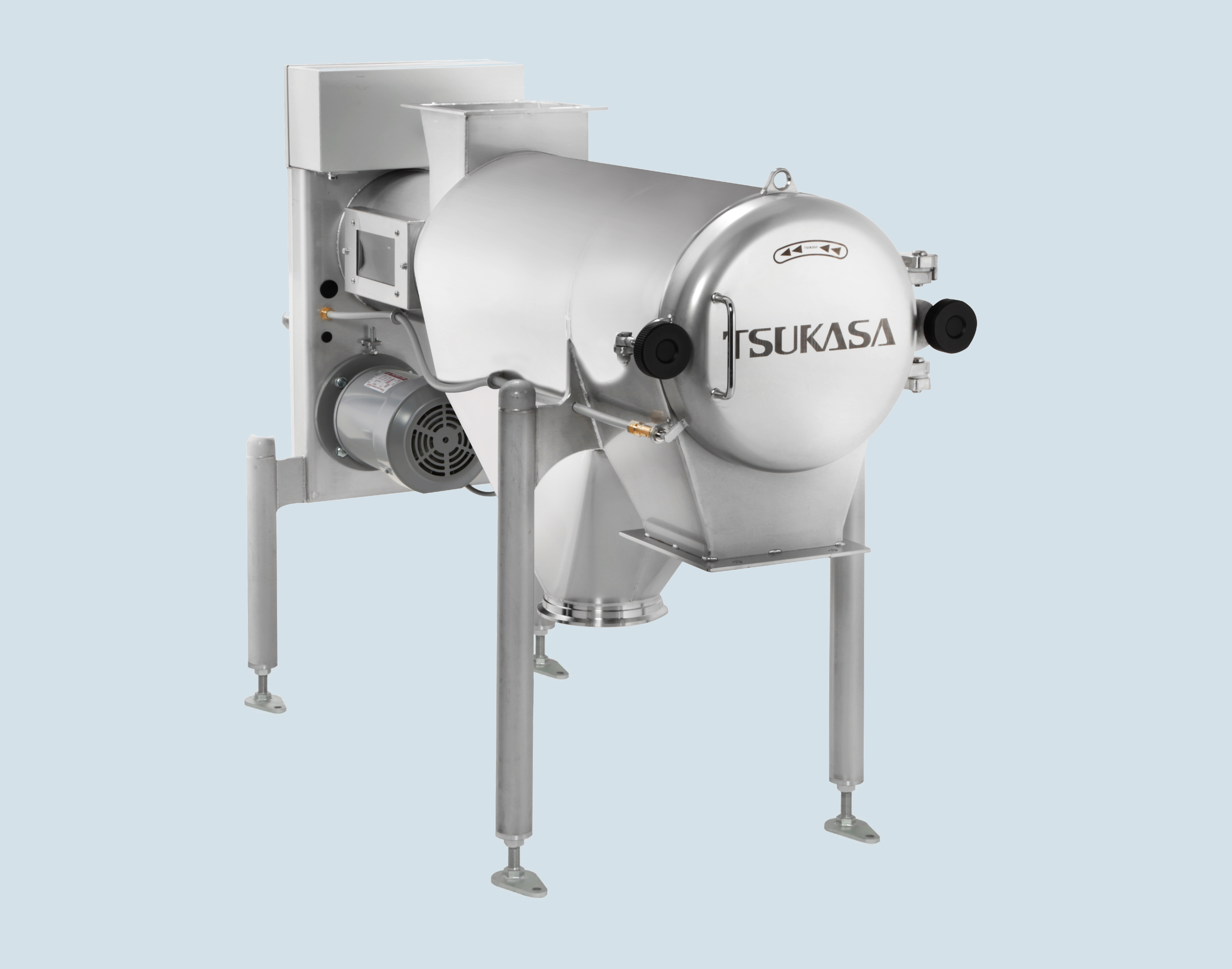

PowConditioner

Powder temperature adjusters that can premix raw materials at the same time as heating or coolingMORE >

PowConditioner CHB type(Vacuum rapid cooling system)

Vacuum rapid cooling system with high cooling efficiencyMORE >

Dryer

Handling Process

Constant conveyance and constant supply, realizing stable discharge

Constant conveyance and constant supply, realizing stable discharge

Quantitative supply equipment

Rotary Valve Cyclone Direct-coupled Model(TLV-C)

Special model directly connected to a cyclone for suction-type pneumatic conveyanceMORE >

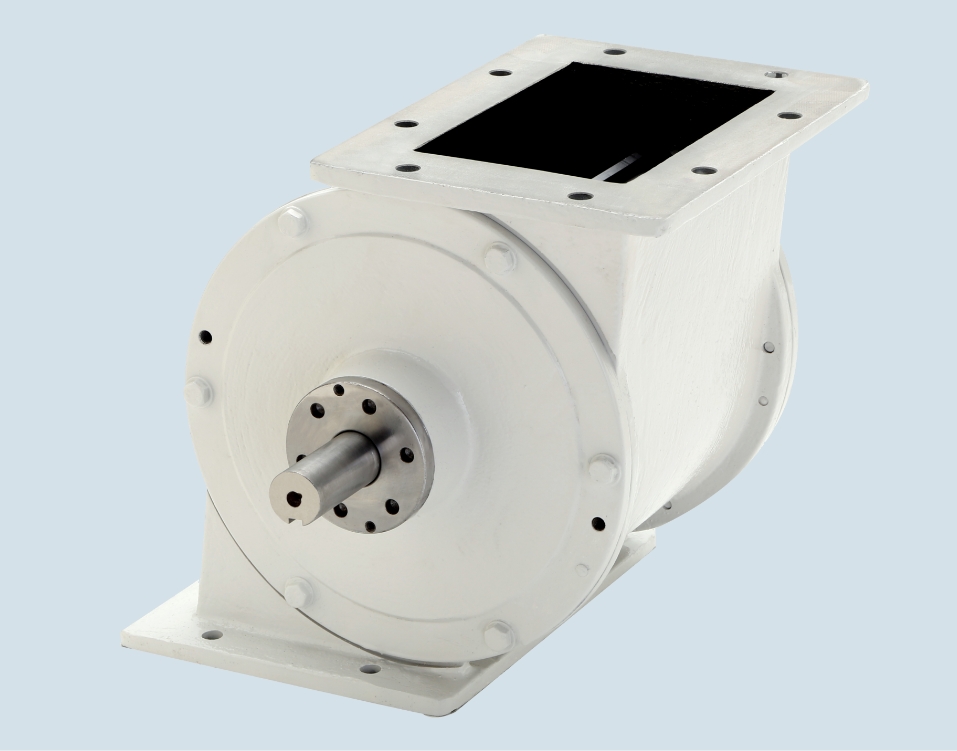

Rotary Valve Eccentric Model(TRS-E)

Constant discharge device which prevents clogging of powder with its eccentric structureMORE >

Rotary Valve Blow-through Model (Motor Direct-coupled)(TFD-D)

Constant discharge device which functions exclusively as the feed source for pneumatic conveyanceMORE >

Rotary Valve Air-lock Model (Motor Direct-coupled)(TLV-D)

Constant discharge device under a receiver or cyclone in the force feed pneumatic conveyanceMORE >

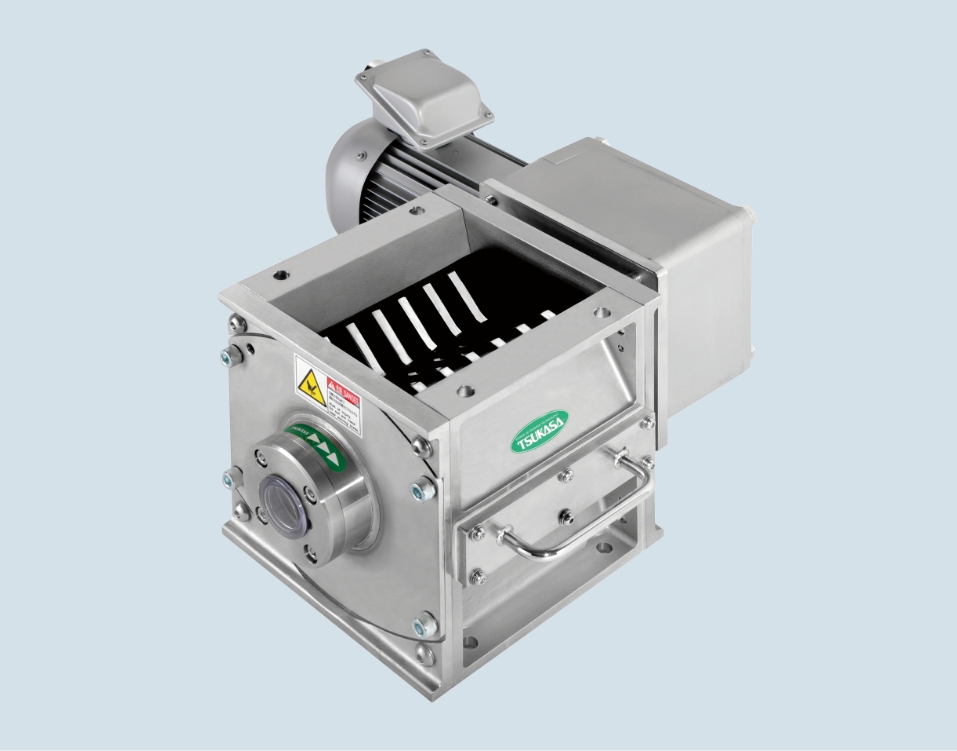

Rotary Valve Blow-through Model(TFD2)

Constant discharge device which functions exclusively as the feed source for pneumatic conveyanceMORE >

Rotary Valve Air-lock Model(TLV2)

Constant discharge device under a receiver or cyclone in pneumatic conveyanceMORE >

Rotary Valve Quantitative Discharge Model(TRS-D1,-DH)

Constant discharge device for places with no vertical pressure differencesMORE >

Screw Feeder(SF)

Feeder optimal for the constant supply of materialsMORE >

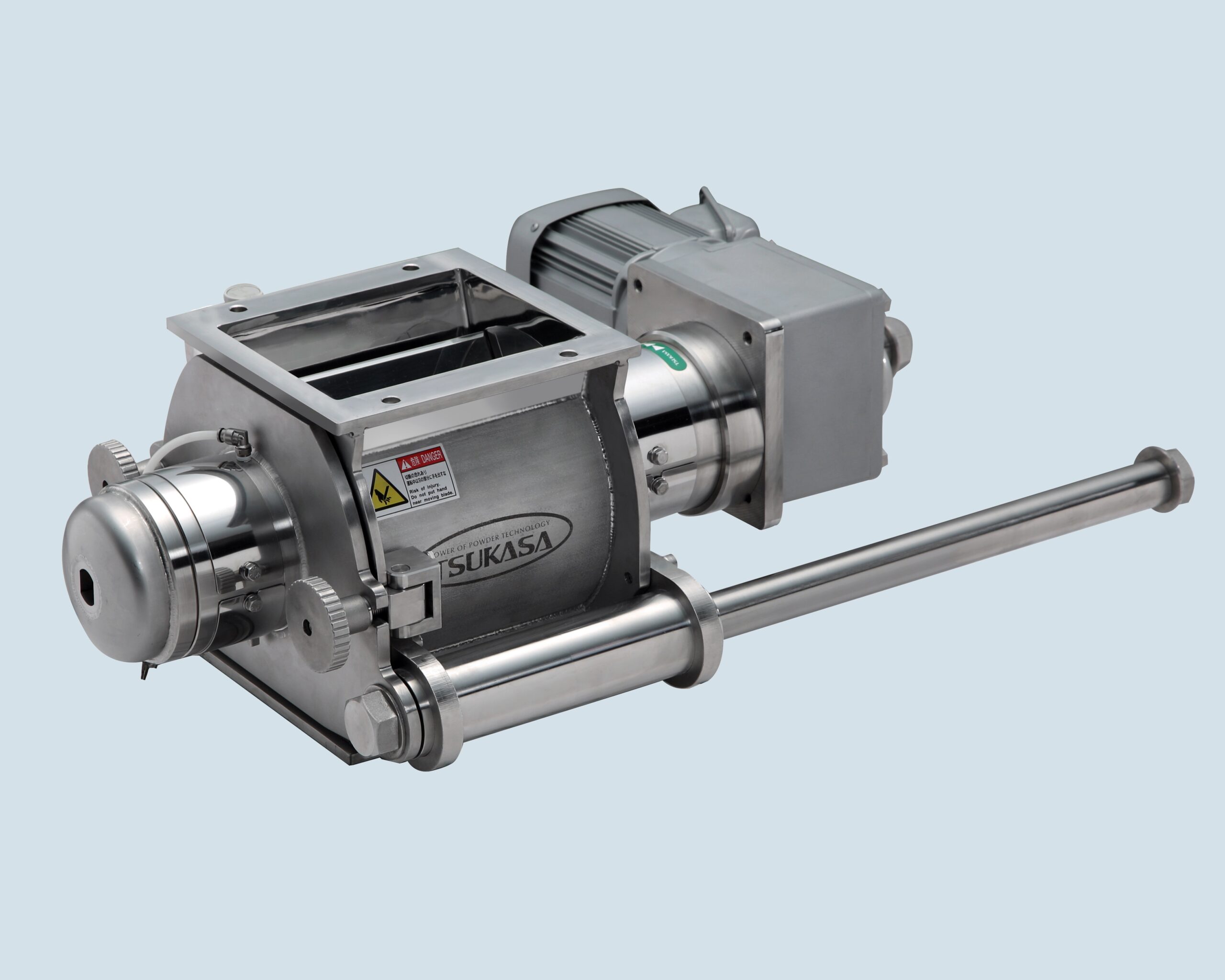

PowRotor FC model

Quantitative discharge equipment that allows the rotor to be washed on the spotMORE >

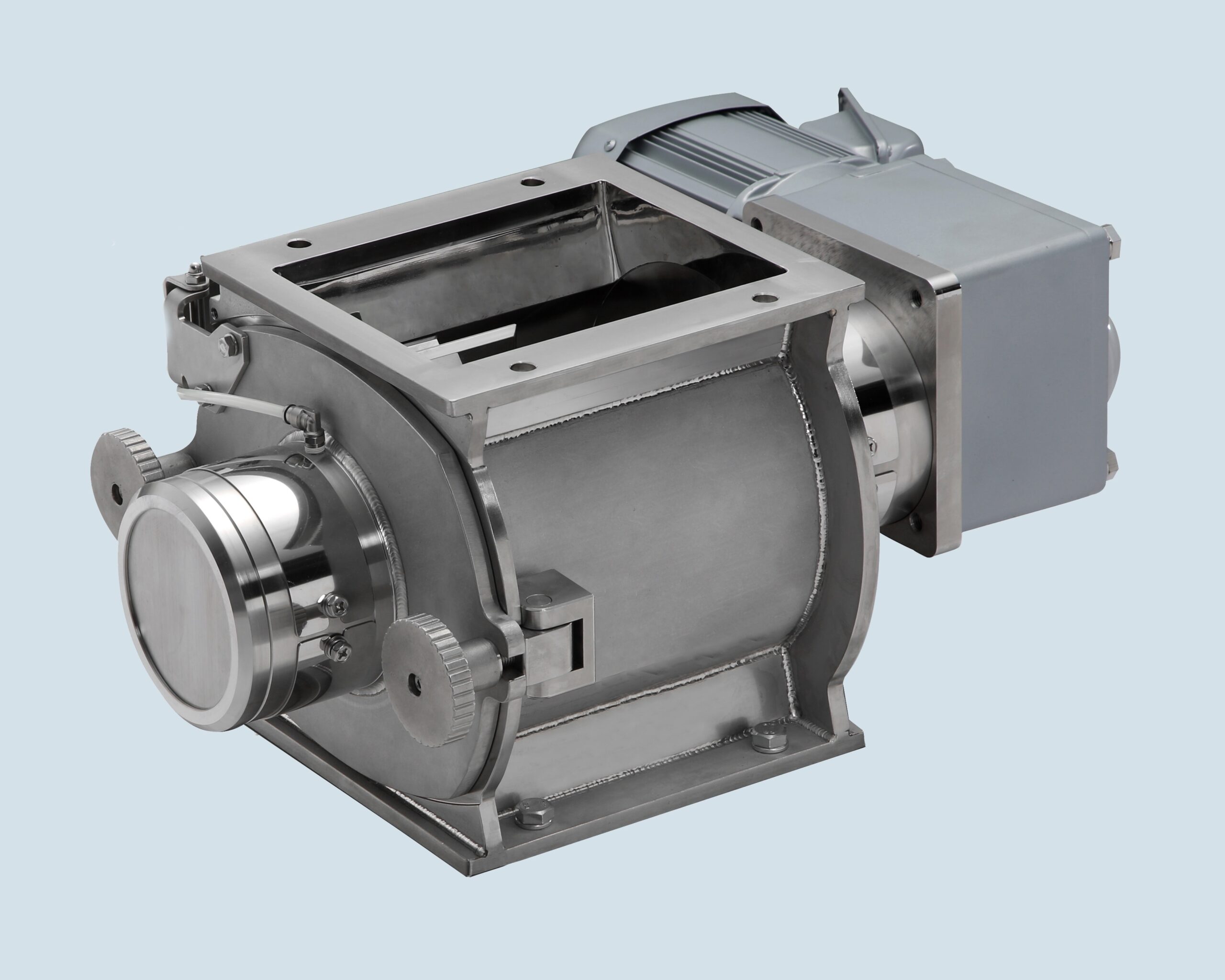

PowRotor FCH model

Lightweight quantitative discharge equipment that allows the rotor to be removed without toolsMORE >

PowRotor Light-weight, Blow-through, Sanitary Model (TRV-LSF)

Constant discharge device which functions exclusively as the feed source for pneumatic conveyanceMORE >

PowRotor Light-weight Sanitary Model (TRV-LS)

Constant discharge device manufactured with our unique precision sheet metal processingMORE >

Conveyance equipment

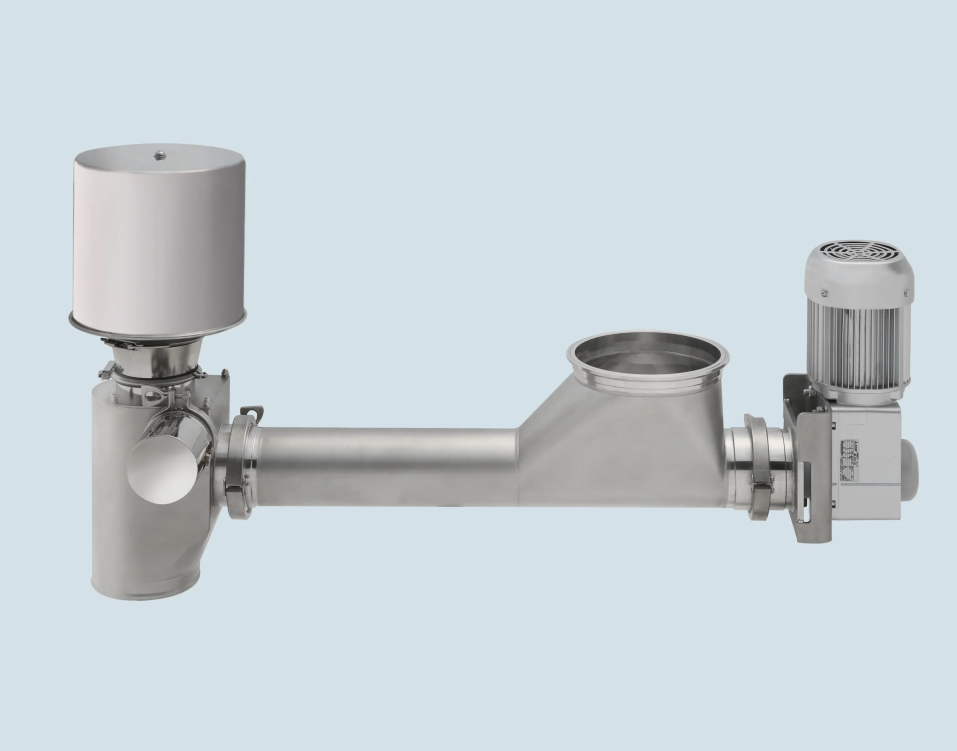

Pulse Feeder(PF)

Conveyance device optimal for conveying fragile powder such as granulation productsMORE >

Pulse Feeder Mini(MP)

Small and space-saving conveyance equipmentMORE >

Others

Valves and Piping parts

A wide variety of valve and piping parts that have superior compatibility

A wide variety of valve and piping parts that have superior compatibility

Dacton Parts

These parts are used for chute conveyance piping.

MORE >

Two-way Valves

These parts switch the powder flow direction with a damper, and changes destinations.

MORE >

Pneumatic Parts

These parts are used for pneumatic conveyance piping.

MORE >

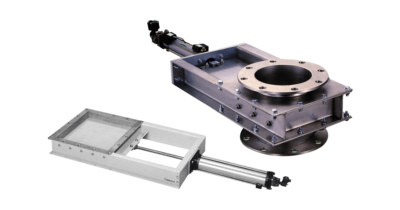

Powder Slide Gate

This slide gate is for powder. We offer the motor type and manual type.

MORE >

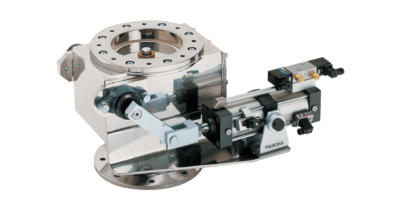

Powder Flap Gate

This flap gate is installed in the discharge port of dust collectors, bottom of cyclones, tanks, bottom of silos, screw feeders, mixers, etc.

MORE >

Multi-directional Distributor

This parts distribute powder to discharge ports if there are a multiple number of them.

MORE >

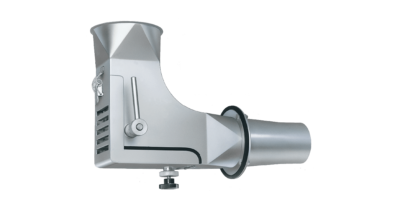

Sampling Equipment

This is a device installed on pneumatic conveyance piping to sample powder flowing inside the pipe.

MORE >

Difficult-to-process materials

We are developing products with difficult-to-process materials that are used in the food, chemical, pharmaceutical and electronic fields.

We are developing products with difficult-to-process materials that are used in the food, chemical, pharmaceutical and electronic fields.

PowMaintenance

Remote monitoring of equipment operation status.

Remote monitoring of equipment operation status.

PowTrace

Achieve visualization in plants

Achieve visualization in plants

Wrong feeding prevention system

To improve productivity by promoting the elimination of human errors

To improve productivity by promoting the elimination of human errors