Crushing and Milling Process

We propose equipment optimal for purposes and materials

We propose equipment optimal for purposes and materials

Mill

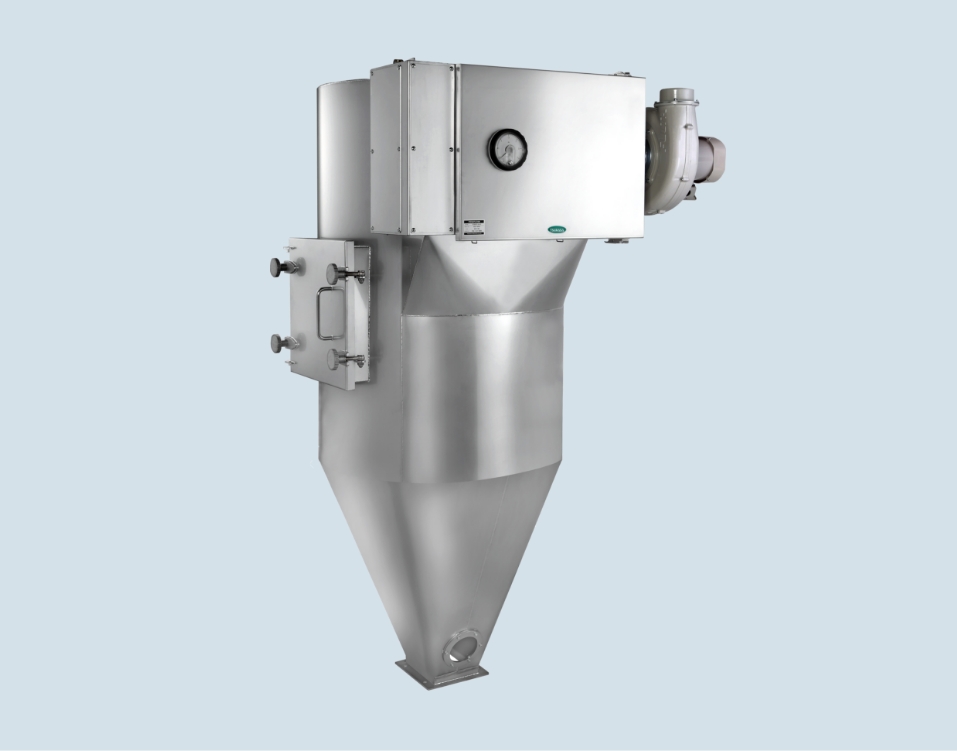

PowJet(PJ)

Dry fine pulverizer utilizing gas-fluid energy

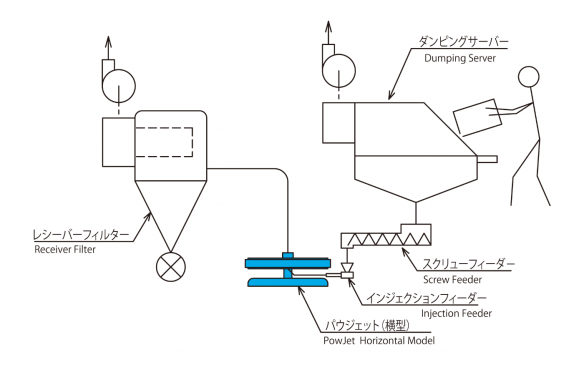

Horizontal Model

*The injection feeder in a photo is optional.

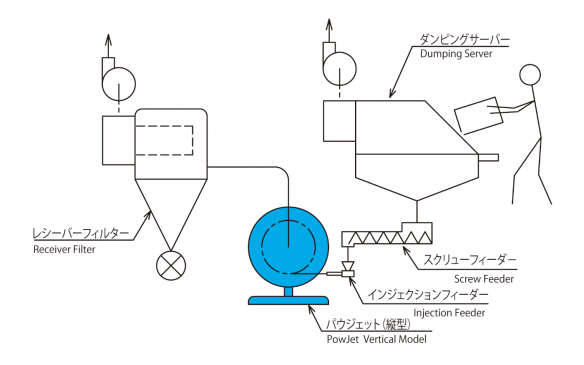

Vertical Model

*The injection feeder in a photo is optional.

Features

⚫︎Dry mill utilizing fluid energies such as compressed air, nitrogen, argon, carbon dioxide gas and others.

⚫︎Optimal for micronizing materials to particle sizes ranging from a few μm to over ten μm.

⚫︎Lower milling temperature realized by pneumatic milling minimizes property change of milled material.

⚫︎Line of products are Vertical Model with higher precision milling capability and Horizontal Model with higher treatment capacity.

⚫︎Integration of compressed air current manifold system resulted in simple design with no pressure hose laid outside of the machine.

⚫︎Light weight structure with no driving parts and fewer components facilitates disassembly and cleaning.

⚫︎Optimal for micronizing materials to particle sizes ranging from a few μm to over ten μm.

⚫︎Lower milling temperature realized by pneumatic milling minimizes property change of milled material.

⚫︎Line of products are Vertical Model with higher precision milling capability and Horizontal Model with higher treatment capacity.

⚫︎Integration of compressed air current manifold system resulted in simple design with no pressure hose laid outside of the machine.

⚫︎Light weight structure with no driving parts and fewer components facilitates disassembly and cleaning.