Operational Testing

Actual equipment test

At the "Powder Technology Center" on the premises of the TSUKASA head office, we have plenty of actual equipment used in powder production lines. Prior to the plants introduction, we can solve customers' concerns and questions such as "Is the selection of this equipment appropriate?" and "Is it possible to obtain powders with such properties?"

Able to conduct an actual equipment test at the actual site

To simulate on-site work, we have prepared a variety of actual equipment unique to a comprehensive powder equipment manufacturer. It is possible to accurately grasp "how and which equipment is operating and what state the powder raw materials will become."

Providing feedback on operational status and test results

The results of the actual equipment test is submitted as a detailed report. We analyze the operation data of the equipment, processing capacity, and whether the powder raw material is in the desired state, and consider introducing it to the actual production line by improving it as necessary.

Also supporting testing in conjunction with the processes before and after

We support not only individual equipment, but also facilitate testing through multiple processes, such as "opening a bag, weighing and mixing raw materials." This enables accurate pre-design of the actual production line and smoother start-up of the production line.

Flow of the actual equipment test

STEP

Inquiry

Inquiry

From the customer's inquiry, the TSUKASA sales representative will conduct a hearing to understand your requests, e.g., "What is the target powder property?"

STEP

Formulate a test plan

Formulate a test plan

What kind of powder raw materials are used, and what kind of equipment is tested under what conditions? We formulate a specific plan, including testing process and scheduling. We also provide you with a quotation.

STEP

Conduct tests

Conduct tests

In the presence of the customer, we conduct actual equipment tests using actual powder raw materials under reliable confidentiality.

STEP

Submit reports

Submit reports

We analyze the test data, submit a detailed report, and provide advice on model selection and improvement points.

Test equipment lineup

We support testing of powder raw materials in a wide range of fields such as food, pharmaceuticals, chemicals, and electronics.

-

Material ReceivingWe test a system that integrates the supply of raw material bags, the opening of bags, and the disposal of empty bags into a single unit.

-

WeighingWe perform tests ranging from large-volume weighing of main raw materials to small-volume weighing of additives.

-

Divider Scale Hybrid 200L(DSC-HV-200)

Material stocker: 200ℓ Weighing range: 500g to 10kg (Apparent specific gravity of 0.5)MORE > -

Divider Scale Terminal Fixed Model(DSC-TDP-5-FX)

Material stocker: 50ℓ Weighing range: 100g to 10kg (Apparent specific gravity of 0.5)MORE > -

Divider Scale Simple(DSC-S)

Ideal for small-scale weighing of raw food materials, pharmaceutical raw materials, and additives, etc.MORE >

-

MixingWe conduct testing for easy and precise mixing of powder with different grain sizes and specific gravity.

-

Sifting and Foreign-material RemovalMetallic foreign material removal using magnets and foreign material removal with a vibrating sieve for classification are supported.

-

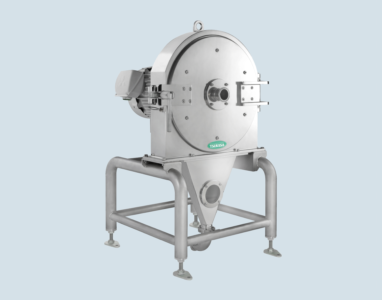

Crushing and MillingSupports micron-level grinding to millimeter-level coarse grinding.

If you want to request or download detailed information, or consult with us about technologies or ask questions about our products, contact us from this page.