Products

Handling Process

Smoothen powder flow.

Quantified and stable transport system.

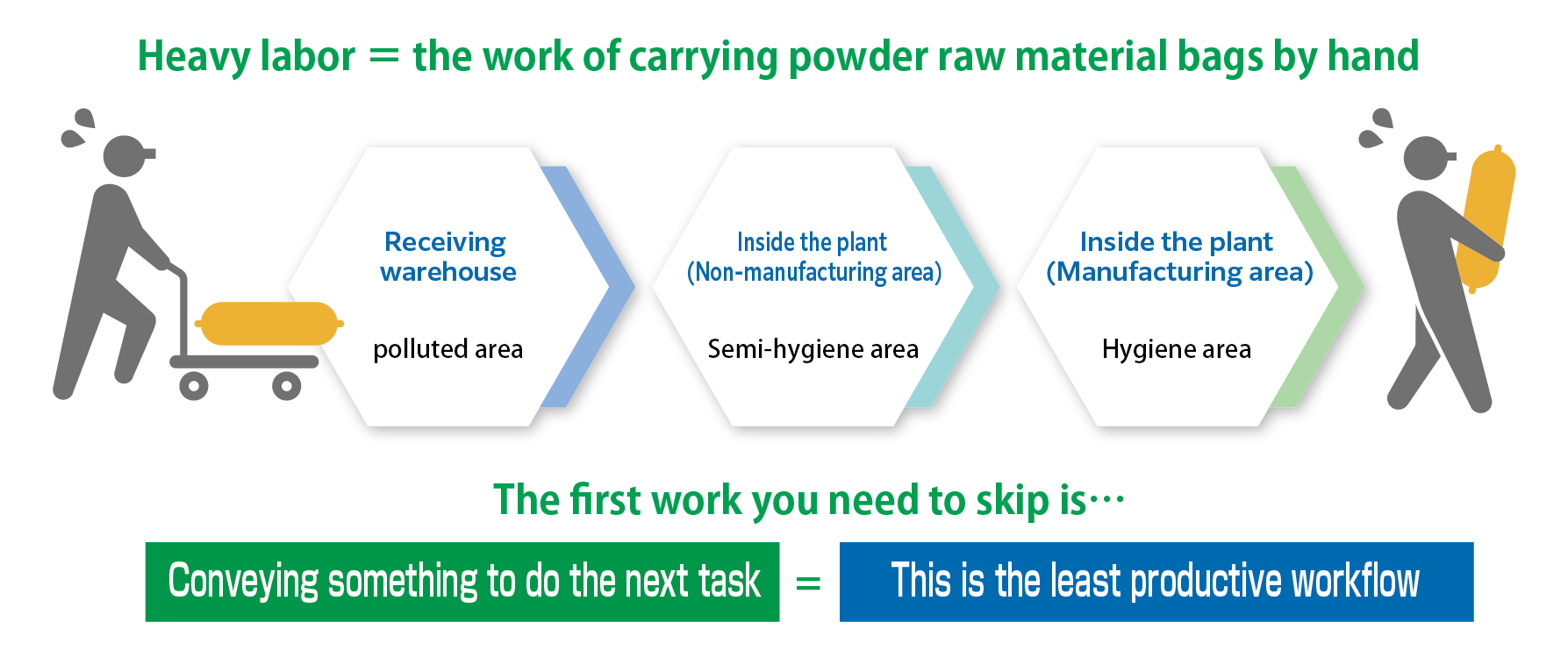

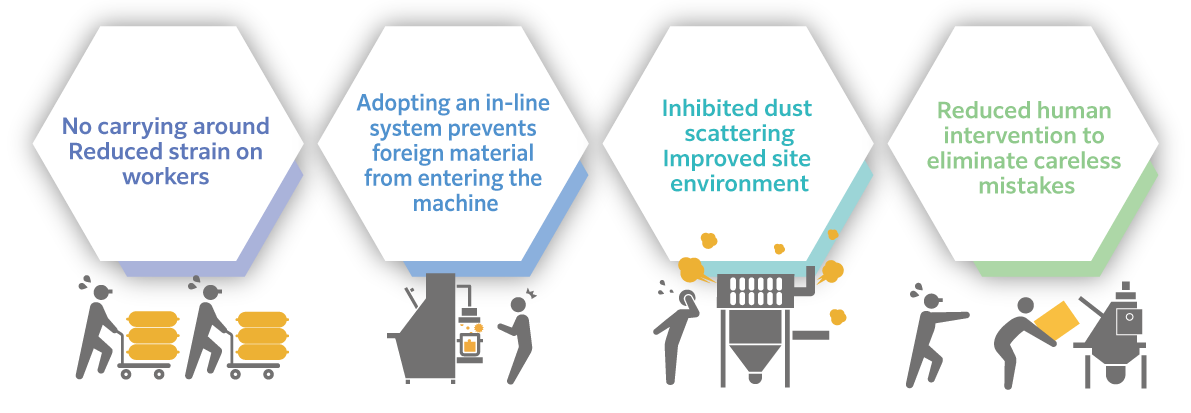

Various handling methods are available according to the characteristics of the powder handled by the customer.

We can propose comprehensive solutions for "powder flow" , from transportation in the factory to quantified supply and discharge in each process and equipment.

We can propose comprehensive solutions for "powder flow" , from transportation in the factory to quantified supply and discharge in each process and equipment.

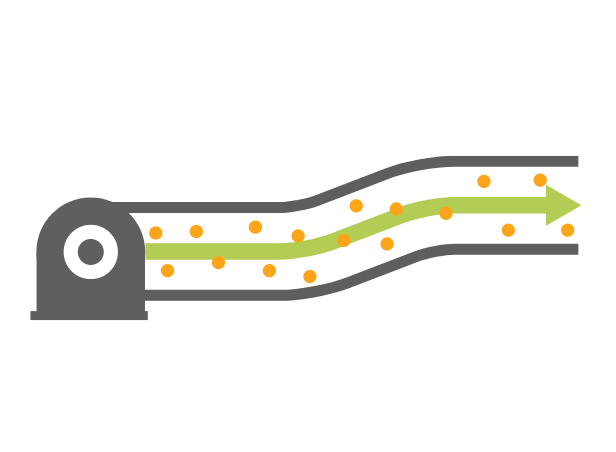

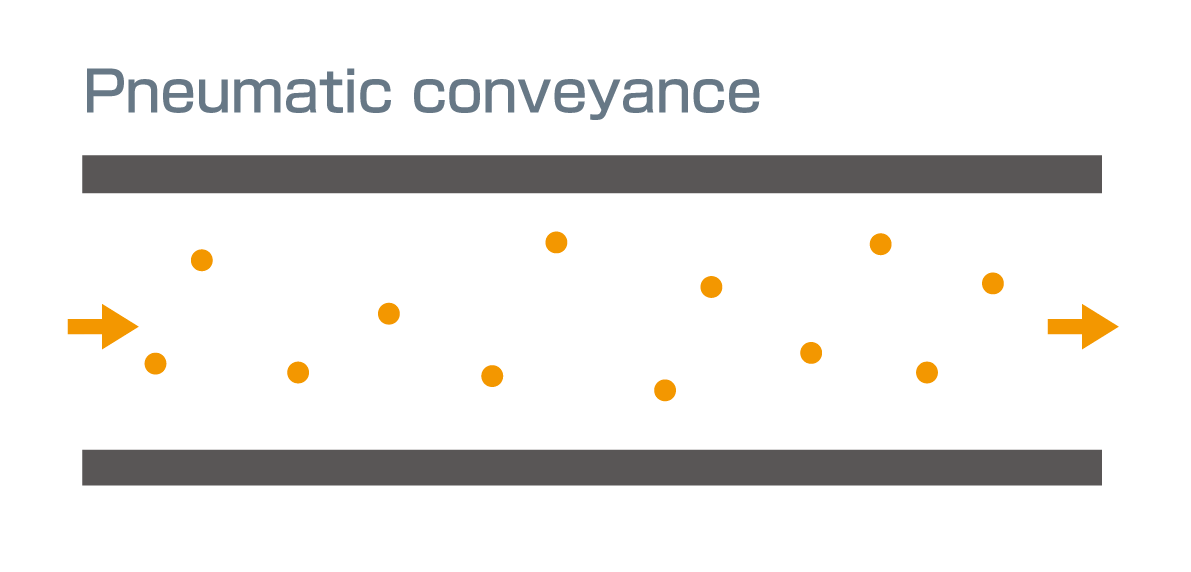

Pneumatic conveyance

The air flow conveys the powder.

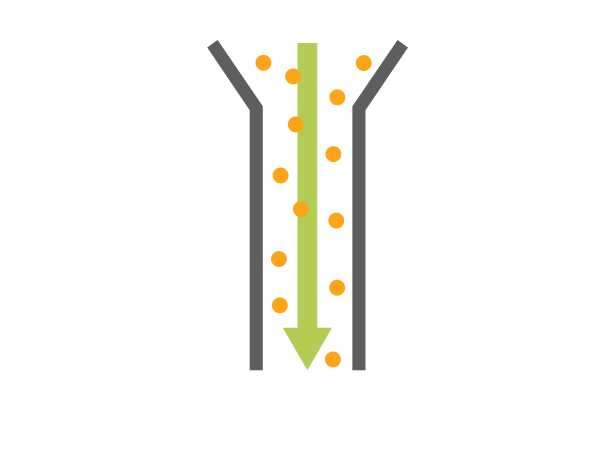

Chute conveyance

The powder is conveyed by its own weight (gravity).

Application examples of TSUKASA's Pneumatic conveyance 1

Changed machine conveyance to pneumatic conveyance

Reduced loss due to residual powder

Machine conveyance (conveyor type) of powder raw materials inevitably accumulates residual powder. To solve this problem, a pneumatic conveyance system was introduced. In addition to reducing residual powder, it can be installed in a small space, reducing the risk of failure and maintenance costs.

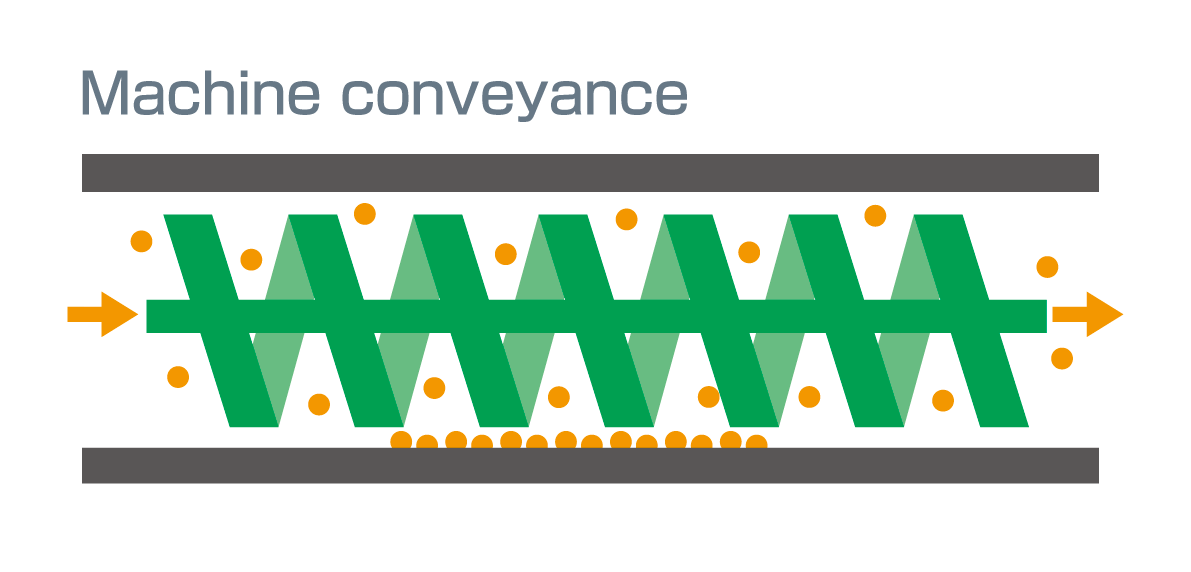

⚫︎ Features of machine conveyance

・Advantages: Able to perform long-distance conveyance.

・Disadvantages: Relatively large amount of residual powder.

There are many mechanical parts, and installation space is required.

Frequent maintenance is required

・Advantages: Able to perform long-distance conveyance.

・Disadvantages: Relatively large amount of residual powder.

There are many mechanical parts, and installation space is required.

Frequent maintenance is required

⚫︎ Features of pneumatic conveyance

・Advantages: Little residual powder.

Able to be installed while saving space.

・Disadvantages: Difficult to convey materials for long distances.

・Advantages: Little residual powder.

Able to be installed while saving space.

・Disadvantages: Difficult to convey materials for long distances.

Application examples of TSUKASA's Pneumatic conveyance 2

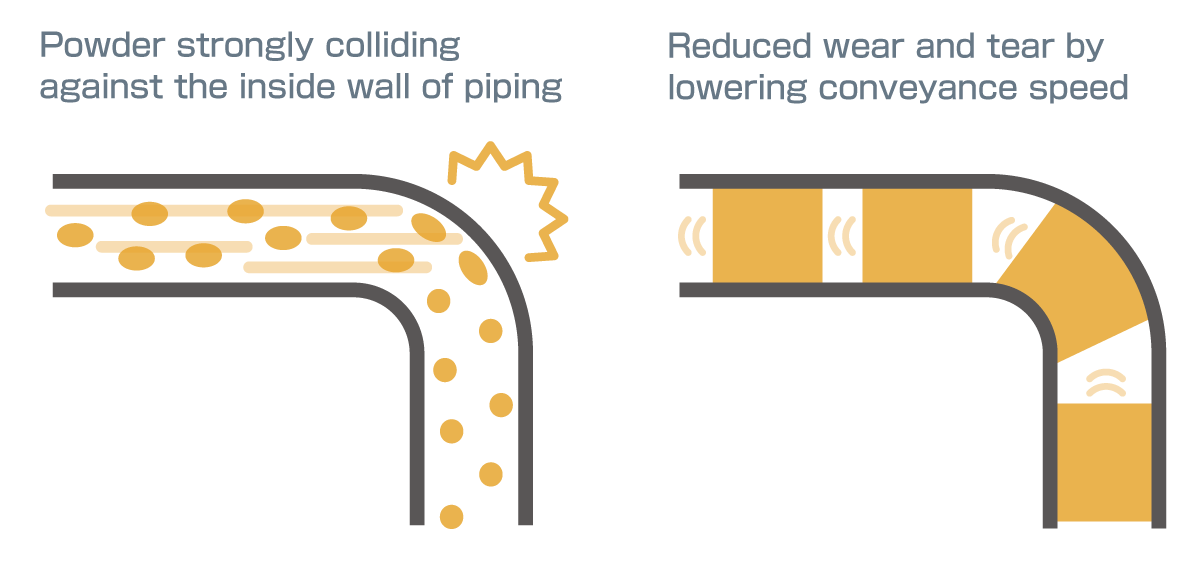

Preventing pipe wear caused by powder

by lowering the conveyance speed

The pneumatic conveyance of highly abrasive resin powders made the bent part of the piping easy to wear. Therefore, we introduced a "Pulse Feeder" that can convey high-density batches at low speed. Long life of piping has been achieved.

Please contact TSUKASA for troubles with powder transportation such as:

▪️Powder transport pipes are prone to clogging

▪️Large loss occurs in residual powder during transport

▪️Highly abrasive powders damage the pipe

▪️Daily cleaning of parts has become a burden

▪️Large loss occurs in residual powder during transport

▪️Highly abrasive powders damage the pipe

▪️Daily cleaning of parts has become a burden

Quantitative supply equipment

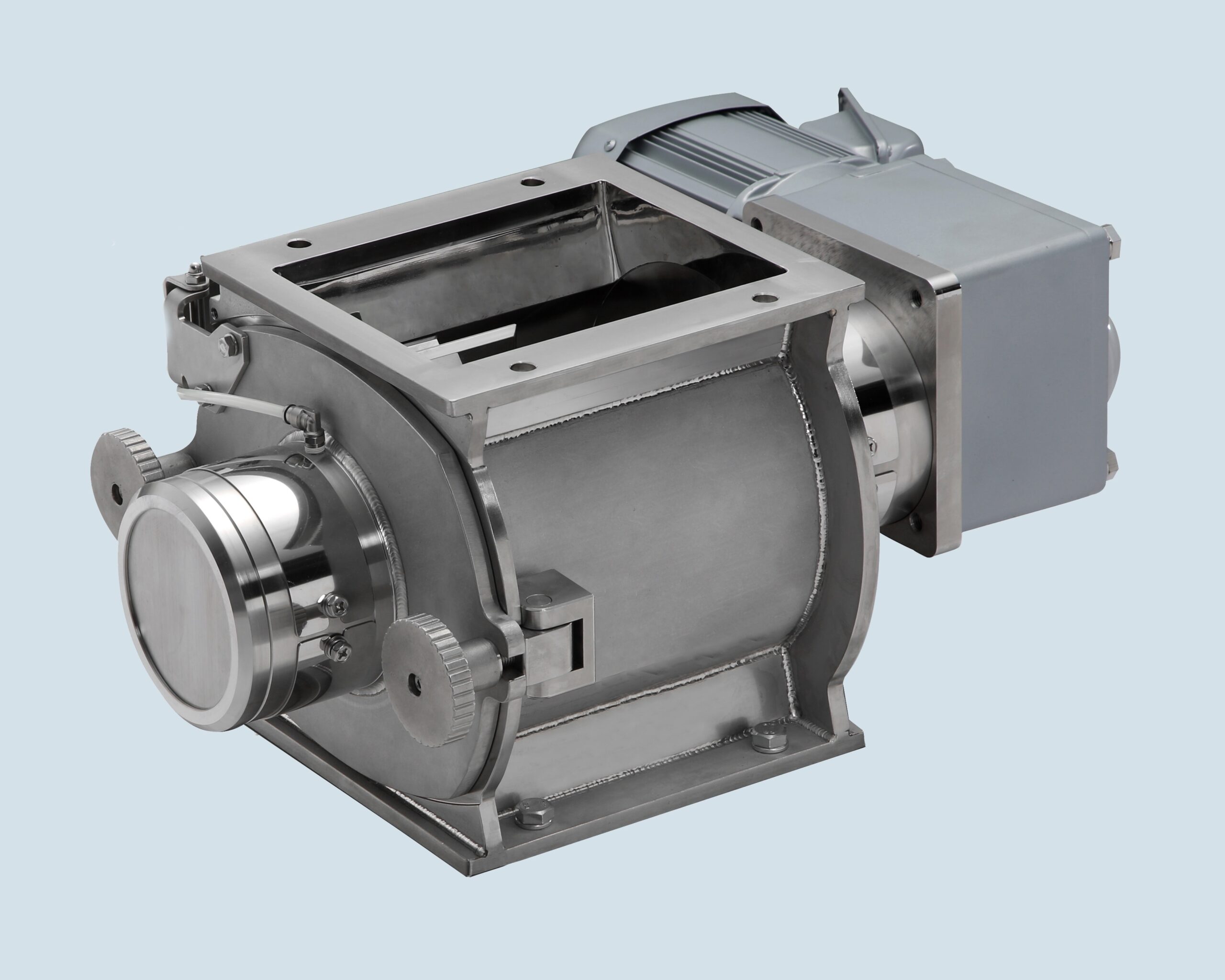

Rotary Valve Cyclone Direct-coupled Model(TLV-C)

Special model directly connected to a cyclone for suction-type pneumatic conveyanceMORE >

Rotary Valve Eccentric Model(TRS-E)

Constant discharge device which prevents clogging of powder with its eccentric structureMORE >

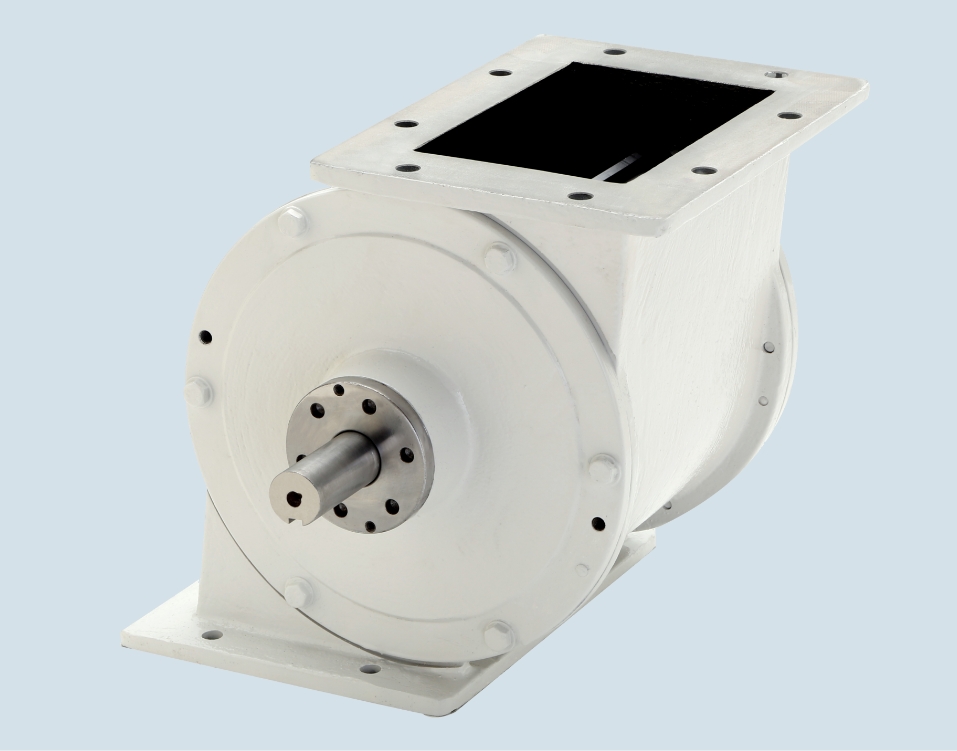

Rotary Valve Blow-through Model (Motor Direct-coupled)(TFD-D)

Constant discharge device which functions exclusively as the feed source for pneumatic conveyanceMORE >

Rotary Valve Air-lock Model (Motor Direct-coupled)(TLV-D)

Constant discharge device under a receiver or cyclone in the force feed pneumatic conveyanceMORE >

Rotary Valve Blow-through Model(TFD2)

Constant discharge device which functions exclusively as the feed source for pneumatic conveyanceMORE >

Rotary Valve Air-lock Model(TLV2)

Constant discharge device under a receiver or cyclone in pneumatic conveyanceMORE >

Rotary Valve Quantitative Discharge Model(TRS-D1,-DH)

Constant discharge device for places with no vertical pressure differencesMORE >

Screw Feeder(SF)

Feeder optimal for the constant supply of materialsMORE >

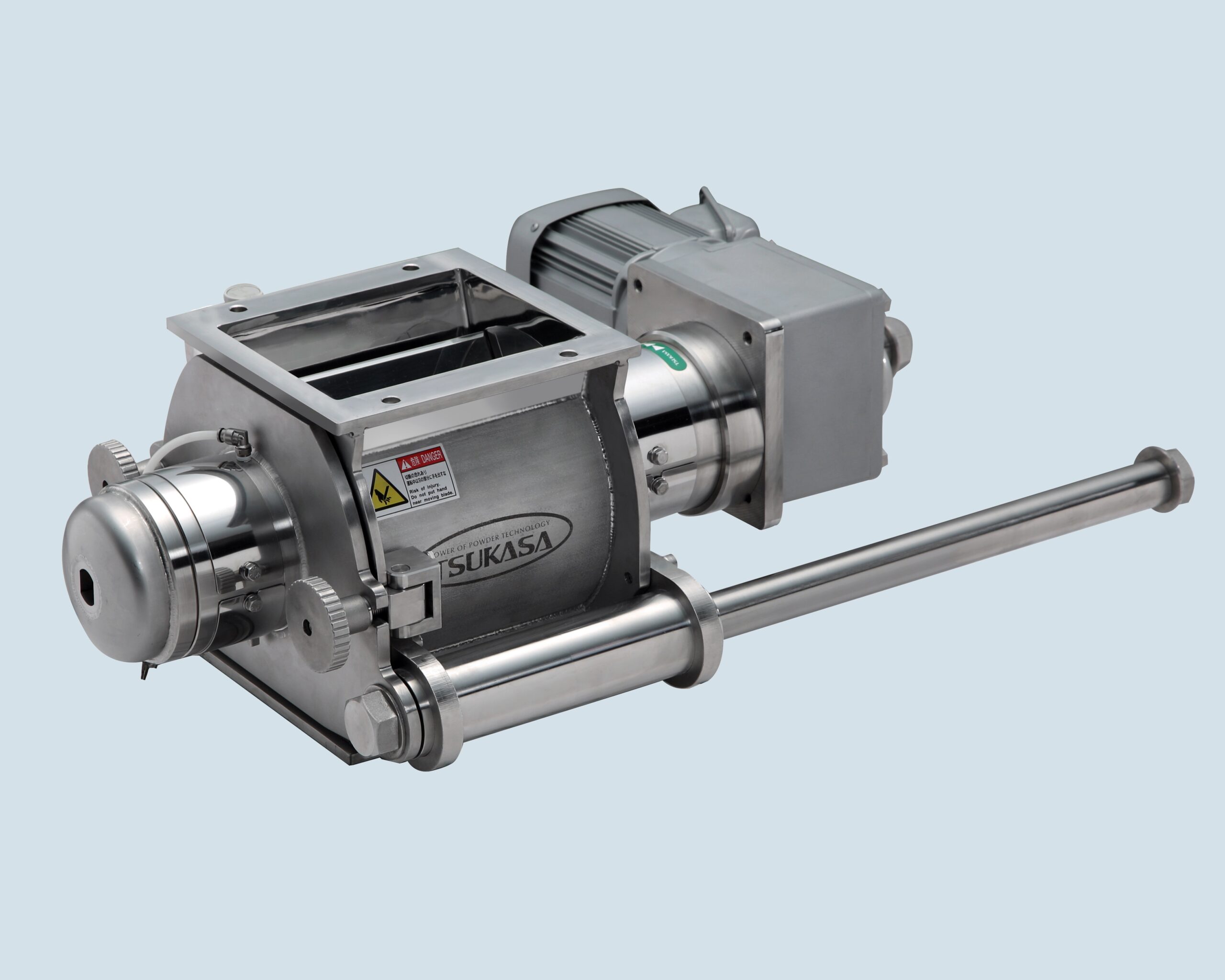

PowRotor FC model

Quantitative discharge equipment that allows the rotor to be washed on the spotMORE >

PowRotor FCH model

Lightweight quantitative discharge equipment that allows the rotor to be removed without toolsMORE >

PowRotor Light-weight, Blow-through, Sanitary Model (TRV-LSF)

Constant discharge device which functions exclusively as the feed source for pneumatic conveyanceMORE >

PowRotor Light-weight Sanitary Model (TRV-LS)

Constant discharge device manufactured with our unique precision sheet metal processingMORE >

Conveyance equipment

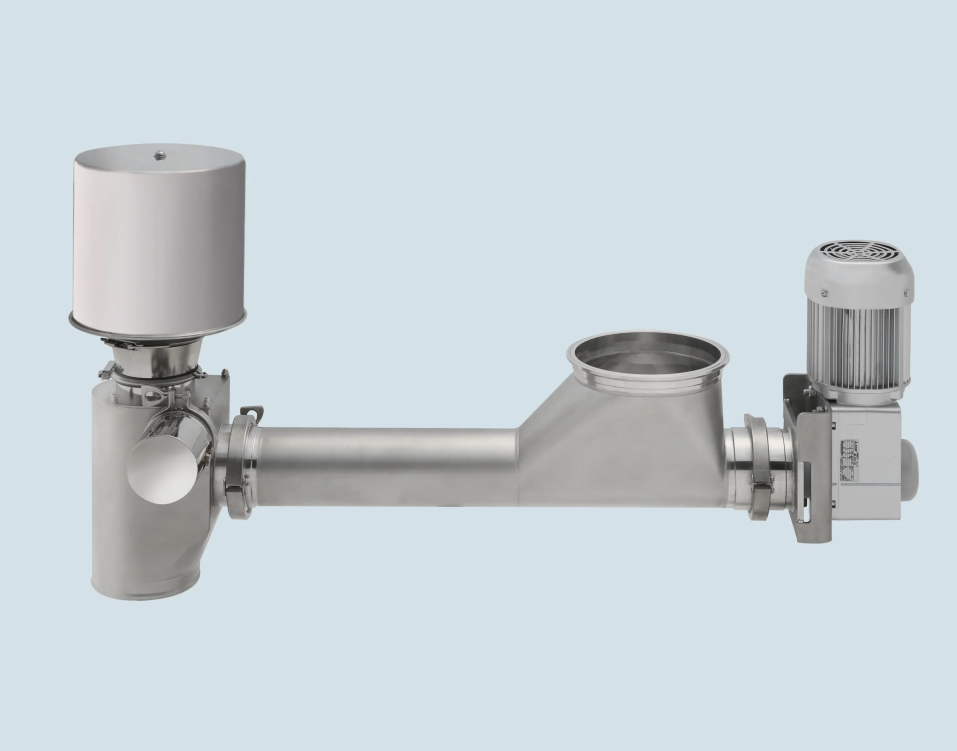

Pulse Feeder(PF)

Conveyance device optimal for conveying fragile powder such as granulation productsMORE >

Pulse Feeder Mini(MP)

Small and space-saving conveyance equipmentMORE >

Others

If you want to request or download detailed information, or consult with us about technologies or ask questions about our products, contact us from this page.