Case Studies

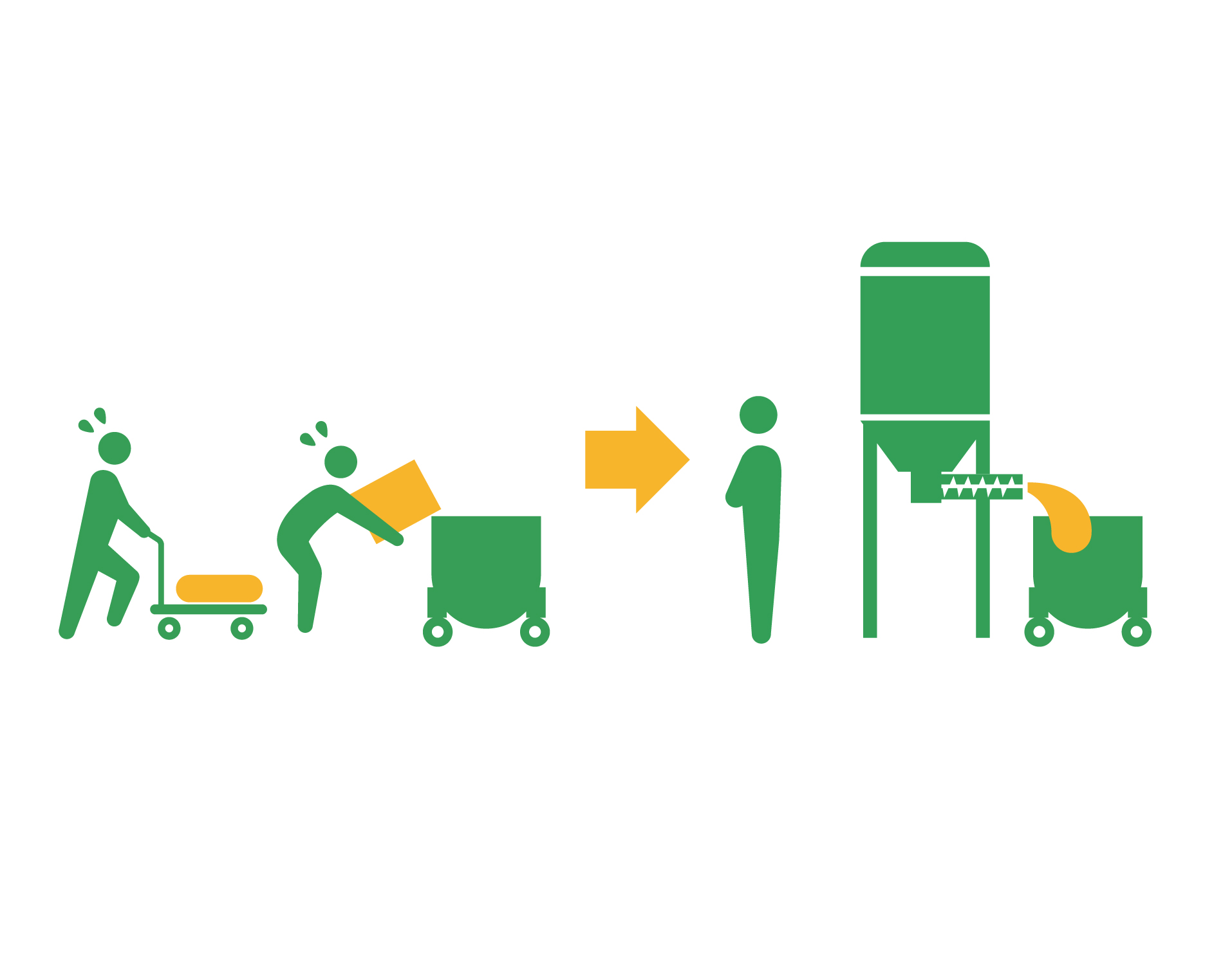

Stabilizes continuous automatic powder feeding at noodle factories

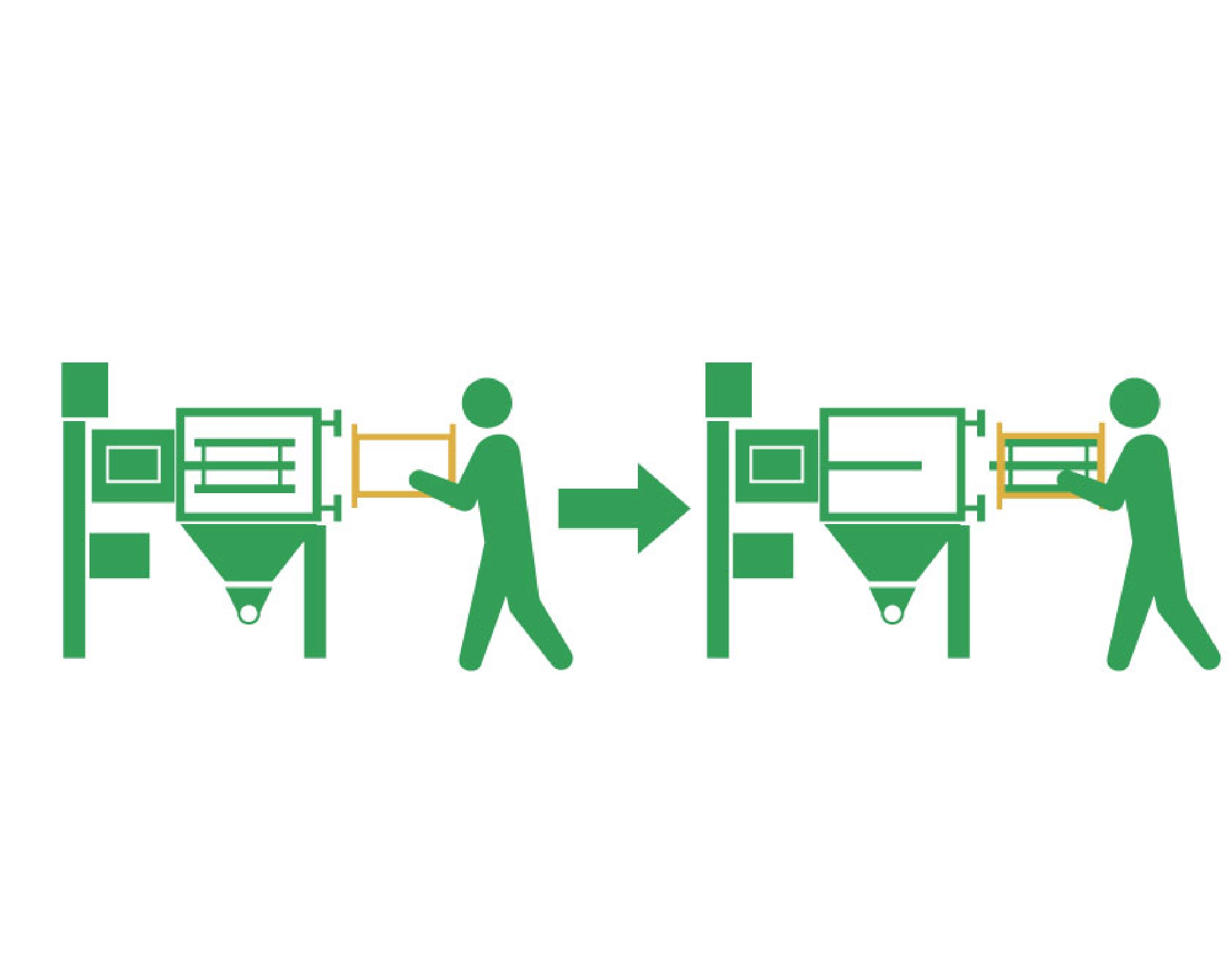

Automatic feeding of powders to movable bowls for bread spiral mixers

High-precision weighing for auxiliary raw materials shortened from “40h” to “8h”!

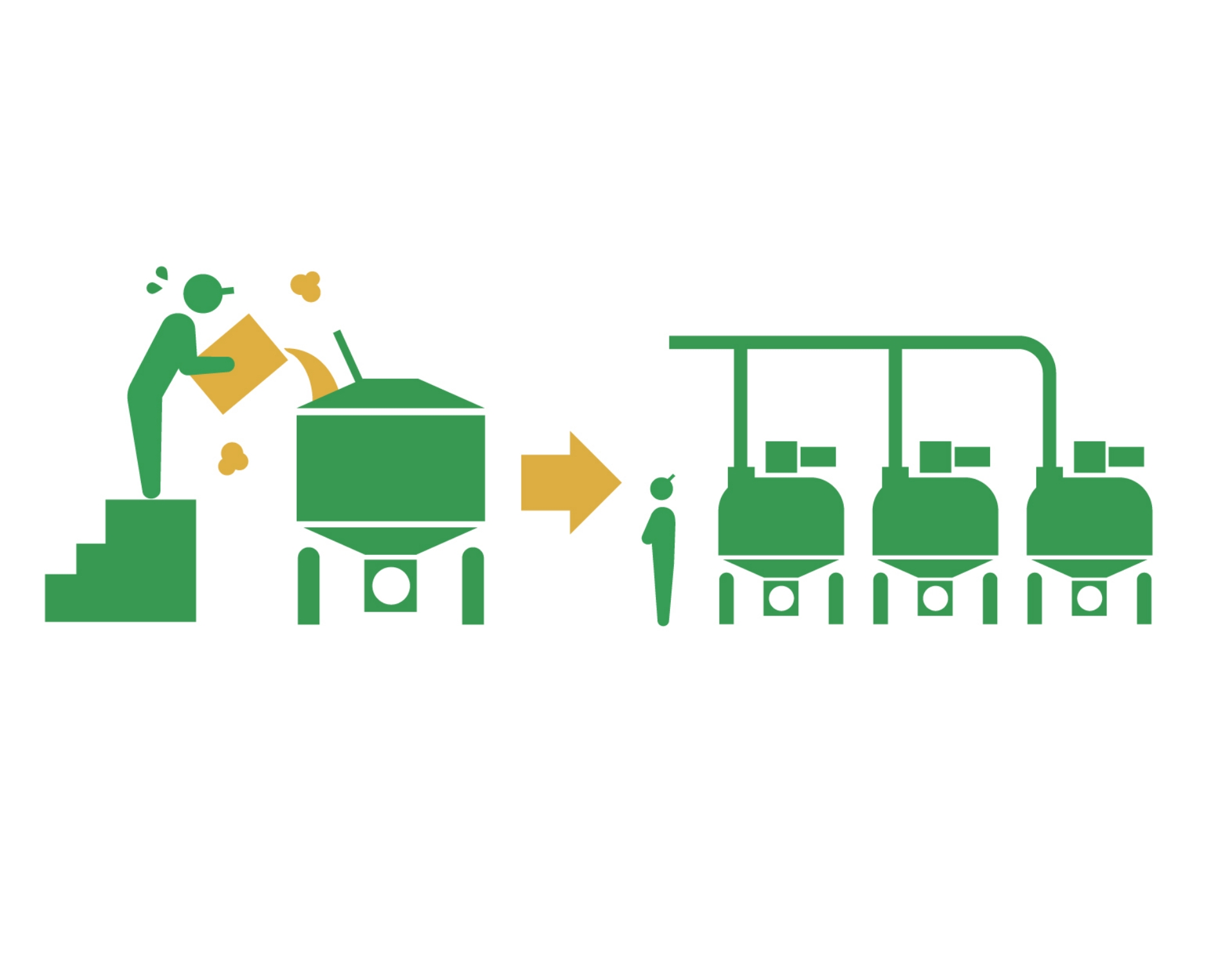

The mixing time in the noodle dough mixer is greatly reduced

Improved direct feeding of raw materials into the dough mixer

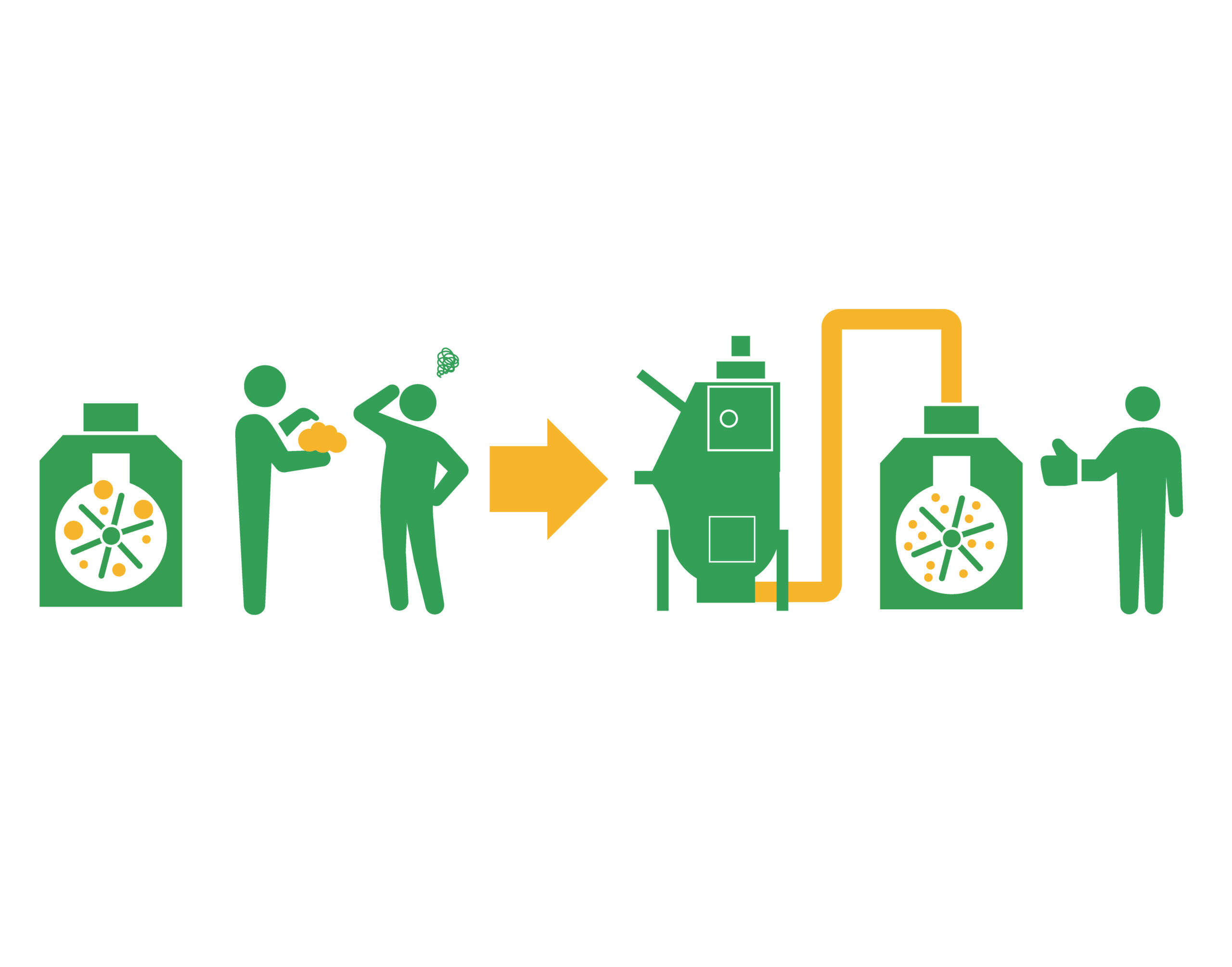

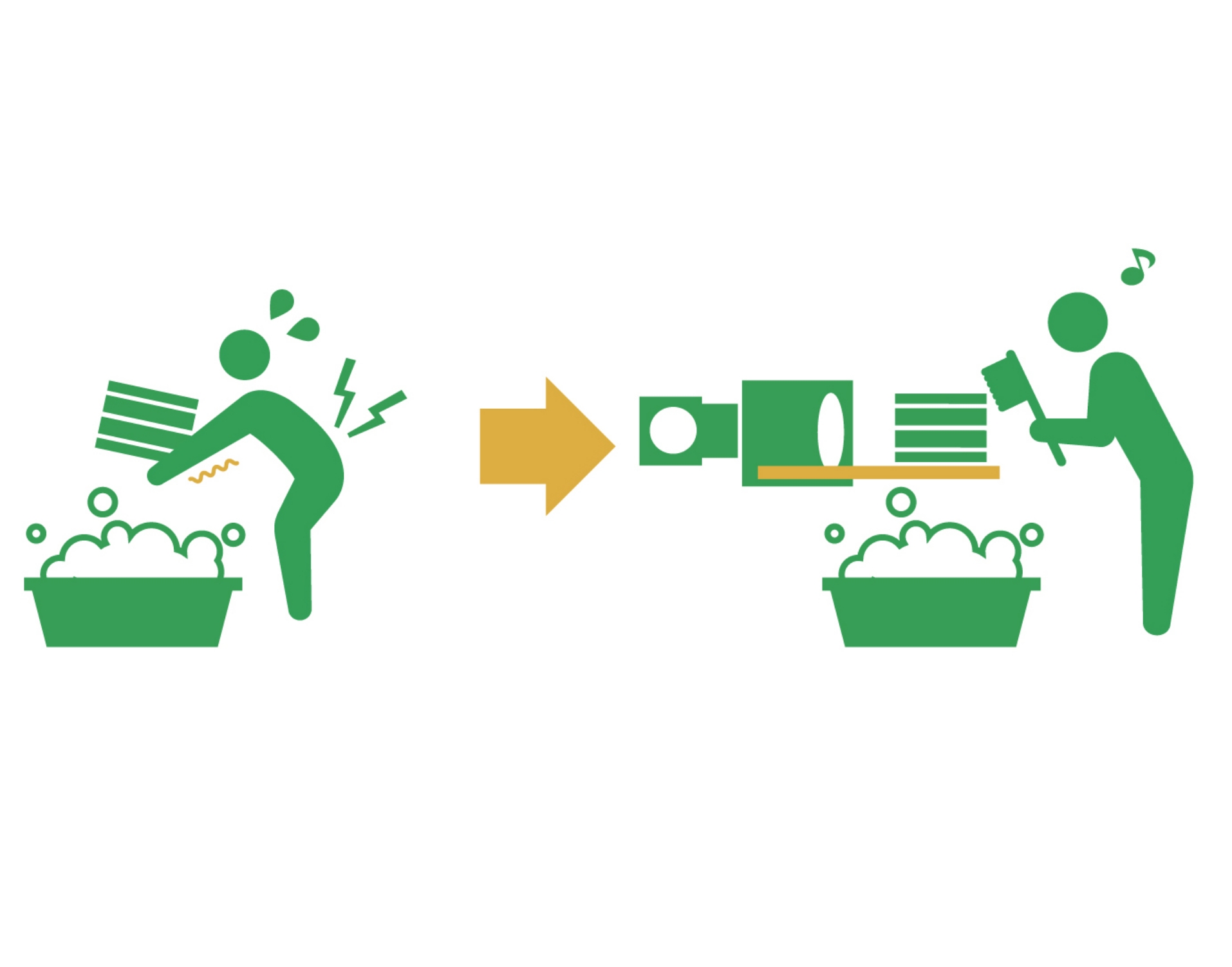

Two models have been developed to simplify rotor washing

Aiming for zero defect rate by supplying bags to bag-opening equipment

Development of a new specification that enables you to see the inside of the sifter from the side

Disassembling and cleaning the sifter is now possible even for new employees

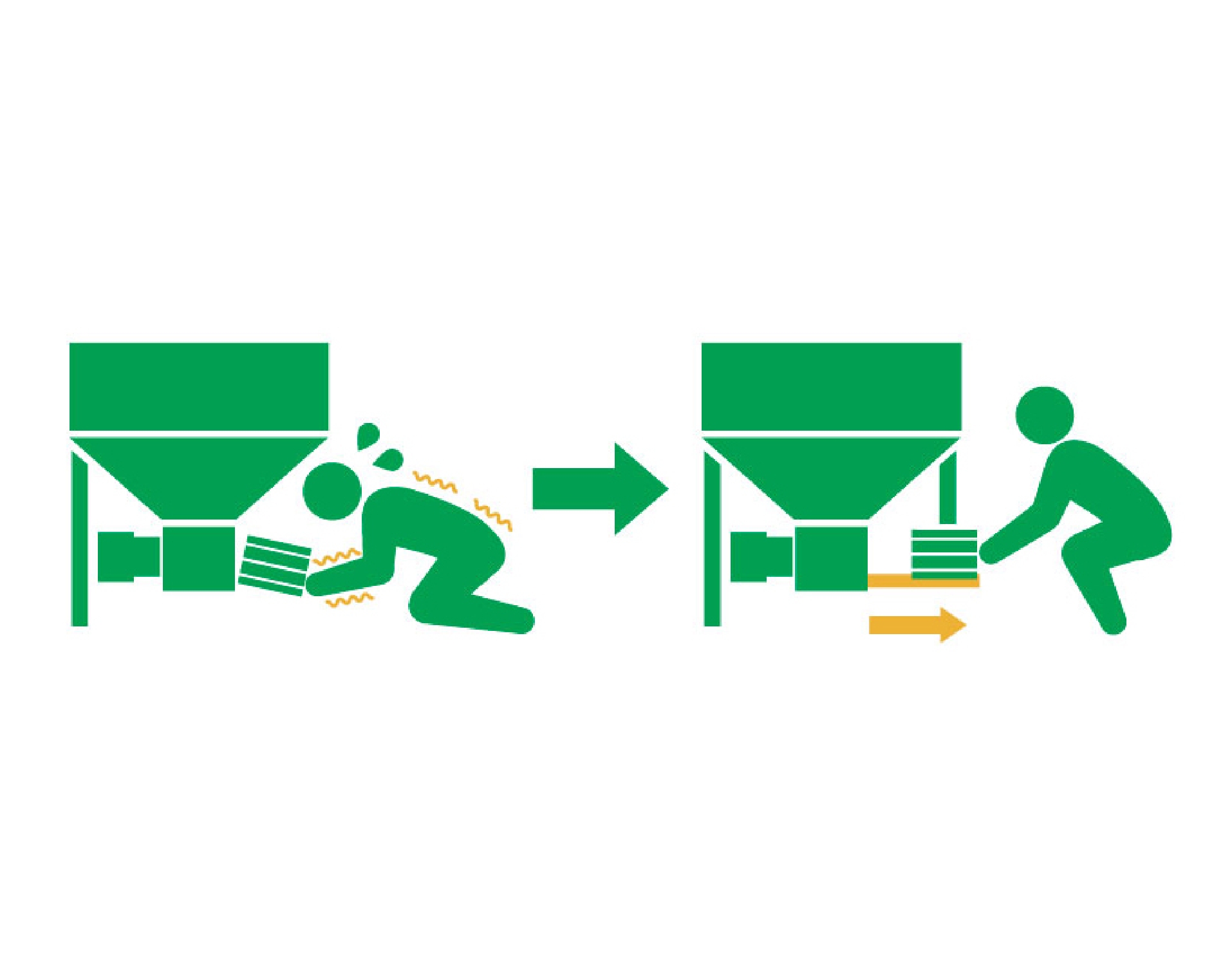

Development of a jig that enables easy removal and refitting of the rotor

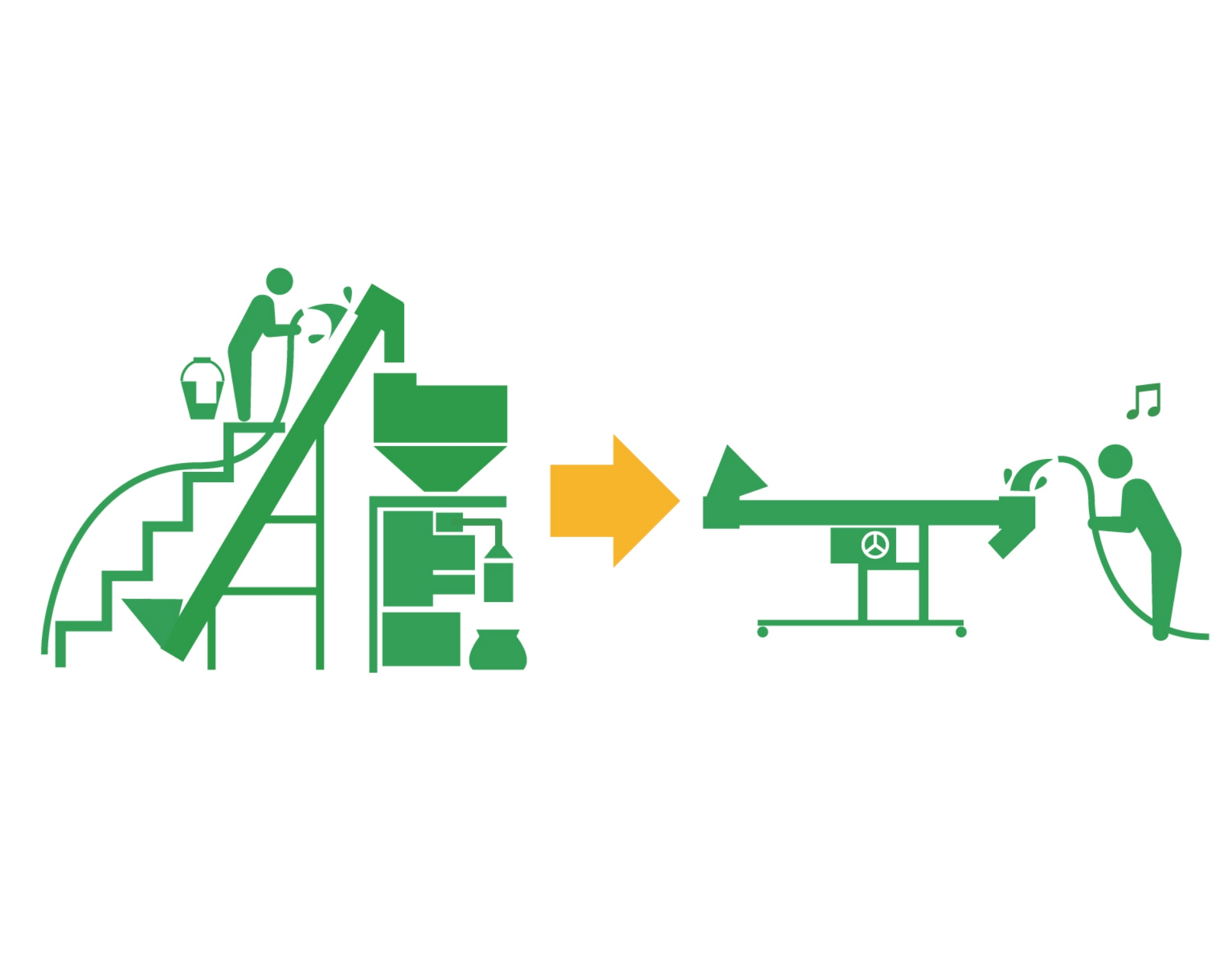

Screw Feeder Tilt Adjustable With Handle

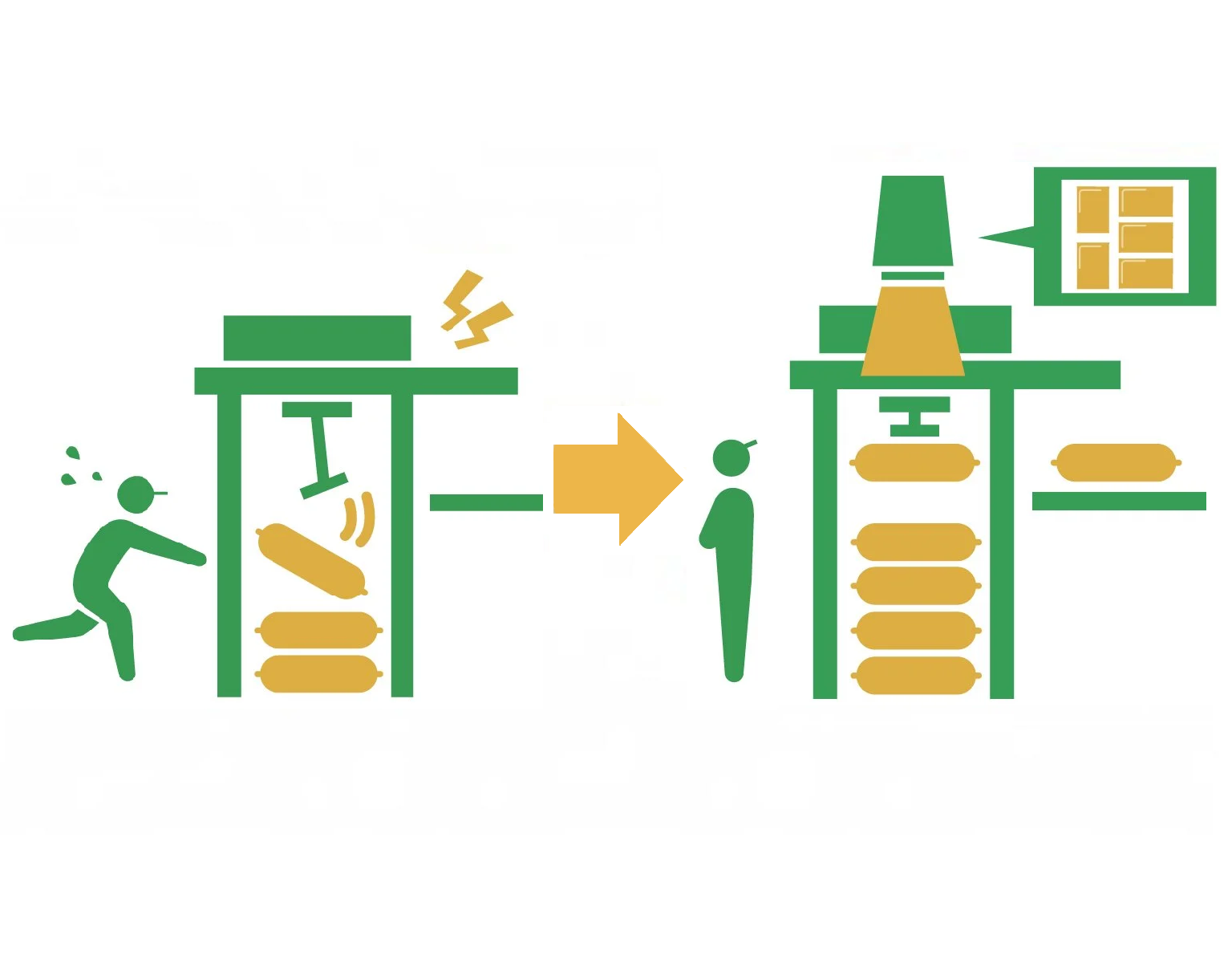

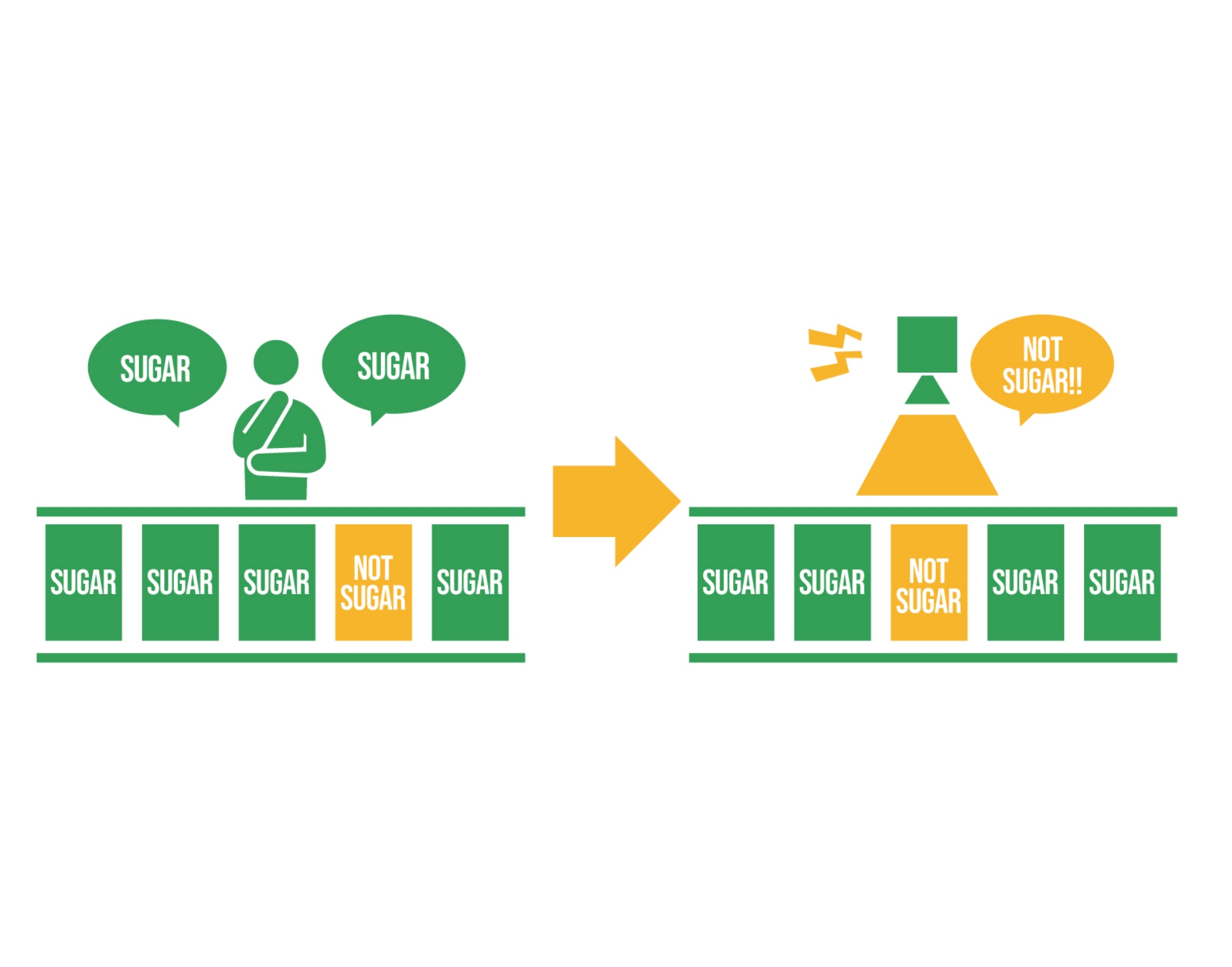

Image recognition shuts out erroneous feeding of powder raw materials