"One-to-one" customized support for each customer

TSUKASA's manufacturing is based on "one-to-one" or original manufacturing. We think together with the customer to find what product is more suitable to the customer's plant or production line and make steady efforts to seek how to achieve manufacturing it. Thus, there is no mass production line in our plants. Dedicated booths are established for each project, and expert staff gather their wisdom to steadily give shape to the customer's original specifications and customized products.

Actively promoting hybrid and in-line systems

Our technologies include a "hybrid system," which integrates various functions into a single unit, and an "in-line system," which organically connects multiple equipment. Compared to the construction of a production line where multiple disparate pieces of equipment are connected somehow, we can offer many advantages such as improved operability, space-saving installation, and lower installation costs and power consumption.

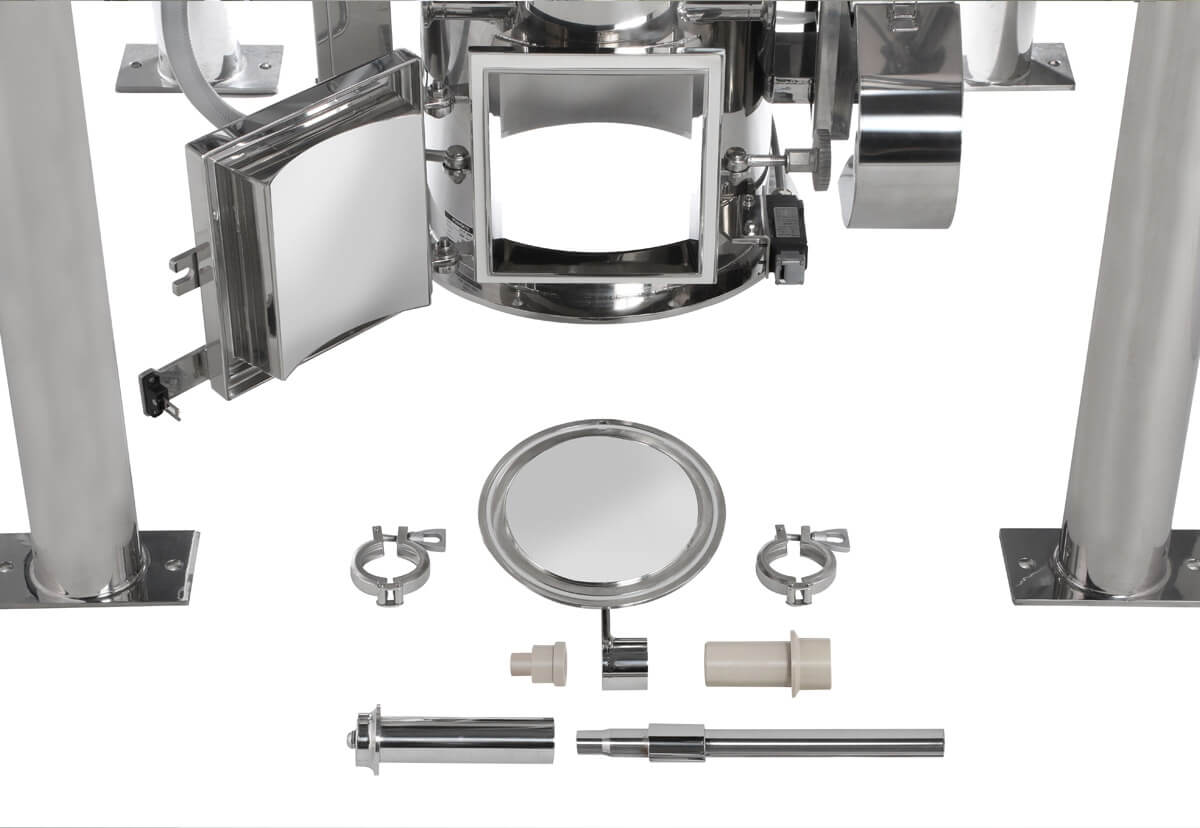

Cannot be insanitary, will not cause any pollution, and is easy to clean if it gets dirty

From large machines to single piping parts, our products are based on our basic concept "Cannot be insanitary, will not cause any pollution, and is easy to clean if it gets dirty."

We support the improvement of the customer's production environment by adopting materials that do not allow powder to adhere, simple designs that prevent powder from entering, development of equipment with built-in dust collectors, and promotion of tool-less disassembly and washing with water without special skills.

We support the improvement of the customer's production environment by adopting materials that do not allow powder to adhere, simple designs that prevent powder from entering, development of equipment with built-in dust collectors, and promotion of tool-less disassembly and washing with water without special skills.

Compatible with "HACCP", "GMP", and "AIB" standards

Food hygiene control standard "HACCP," food and pharmaceutical manufacturing standard "GMP," and "AIB standard" for the baking and flour milling industry. TSUKASA's powder equipment is conceived with "meeting strict international standards" in mind at all stages from development, design, manufacturing, and actual operation, and we can reliably help our customers to meet these standards at their plant.

Delivering to the customer after the test on an actual machine at the customer's plant

Starting with listening to the customer's requests, we proceed to designing, prototyping, and conducting operation tests, and install the equipment at the customer's plant, as well as perform trial operations as necessary. We then thoroughly verify the operation of the equipment to ensure that the entire production line works smoothly. Further fine adjustments and custom settings are implemented to deliver the equipment to the customer with the best possible performance.