Material Receiving and Powder Feeding Process

Achieved Speedy and efficient reception and supply of materials

Achieved Speedy and efficient reception and supply of materials

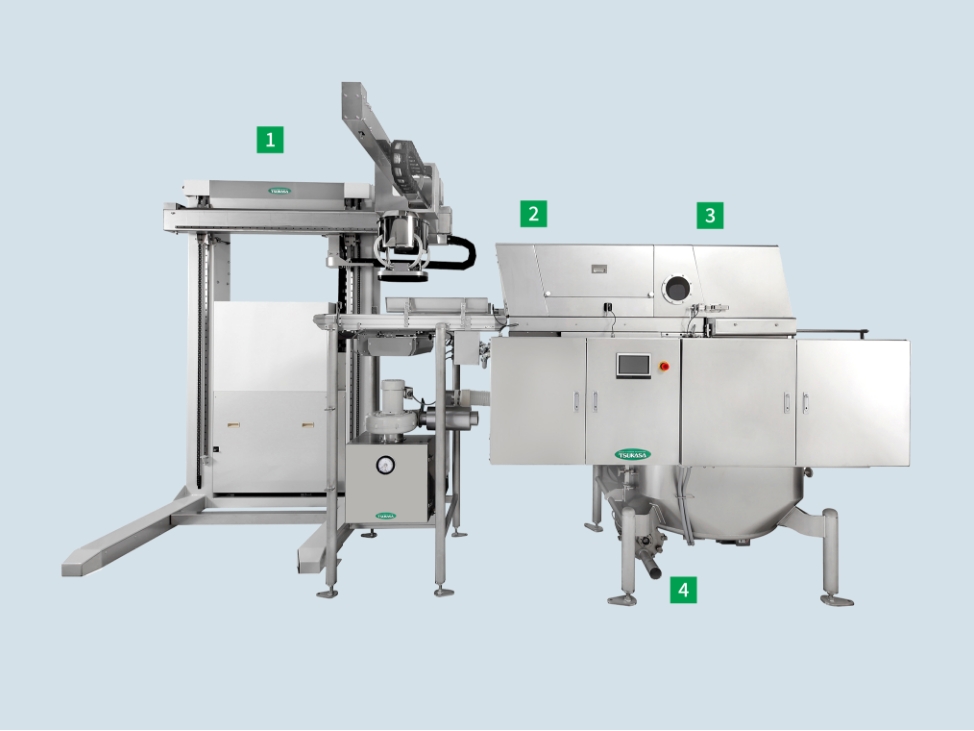

Automatic bag opening System

Automatic bag opening System

A system equipped with functions for bag supply, surface cleaning, and bag opening

①Depalletizer robo

A special suction mechanism enables rapid bag feeding.

Articulated robot specification available for operations involving multiple pallets.

②Sack Cleaner

Cleans bag surface with high pressure air.

③PowOpener

Processes up to 200 bags/hour with a 99.9% raw material recovery rate, thanks to a specialized opening mechanism.

(Performance may vary depending on raw material type, bag shape, and required capacity.)

④PowRotor

It is the rotary valve for pneumatic transportation designed lightweight and compact.

A special suction mechanism enables rapid bag feeding.

Articulated robot specification available for operations involving multiple pallets.

②Sack Cleaner

Cleans bag surface with high pressure air.

③PowOpener

Processes up to 200 bags/hour with a 99.9% raw material recovery rate, thanks to a specialized opening mechanism.

(Performance may vary depending on raw material type, bag shape, and required capacity.)

④PowRotor

It is the rotary valve for pneumatic transportation designed lightweight and compact.

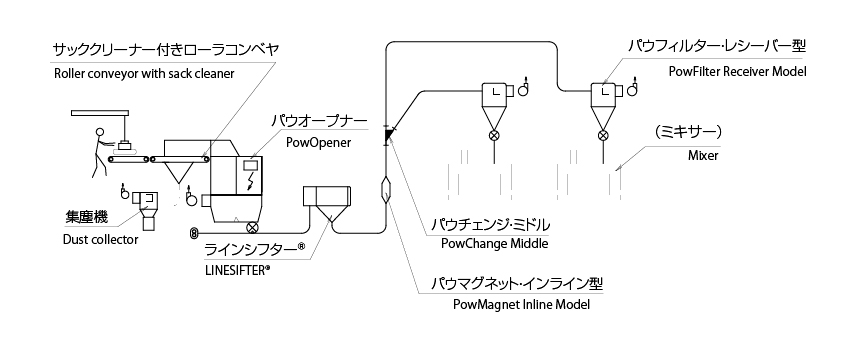

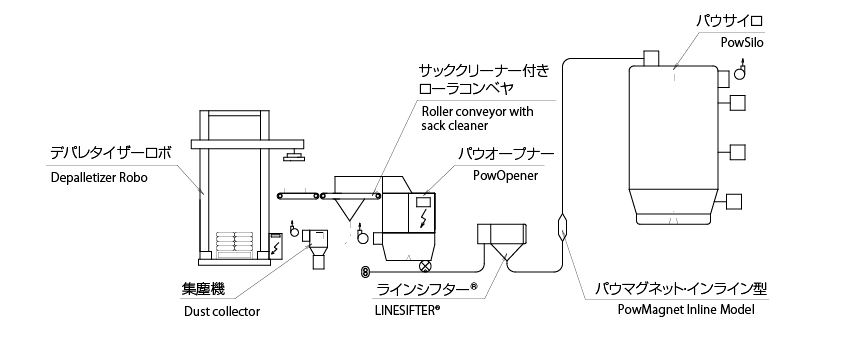

System Overview

⚫︎A compact all-in-one system that integrates bag supply, surface cleaning, bag opening, and empty bag disposal—all essential functions for the bag opening and powder feeding process—into a single unit.

⚫︎There is little paper powder generated when the bag is opened by a special processing cutter.

⚫︎The single-unit design inhibits contamination by germs and other foreign matter, resisting soiling and helping to ensure an attractive appearance.The built-in dust collector prevents scattering of raw materials to the outside and does not pollute the working environment.

⚫︎Easy access for internal inspection, maintenance, and cleaning ensures outstanding sanitary performance. Models with components that can be disassembled are also available, allowing internal cleaning with water.

⚫︎There is little paper powder generated when the bag is opened by a special processing cutter.

⚫︎The single-unit design inhibits contamination by germs and other foreign matter, resisting soiling and helping to ensure an attractive appearance.The built-in dust collector prevents scattering of raw materials to the outside and does not pollute the working environment.

⚫︎Easy access for internal inspection, maintenance, and cleaning ensures outstanding sanitary performance. Models with components that can be disassembled are also available, allowing internal cleaning with water.