Products

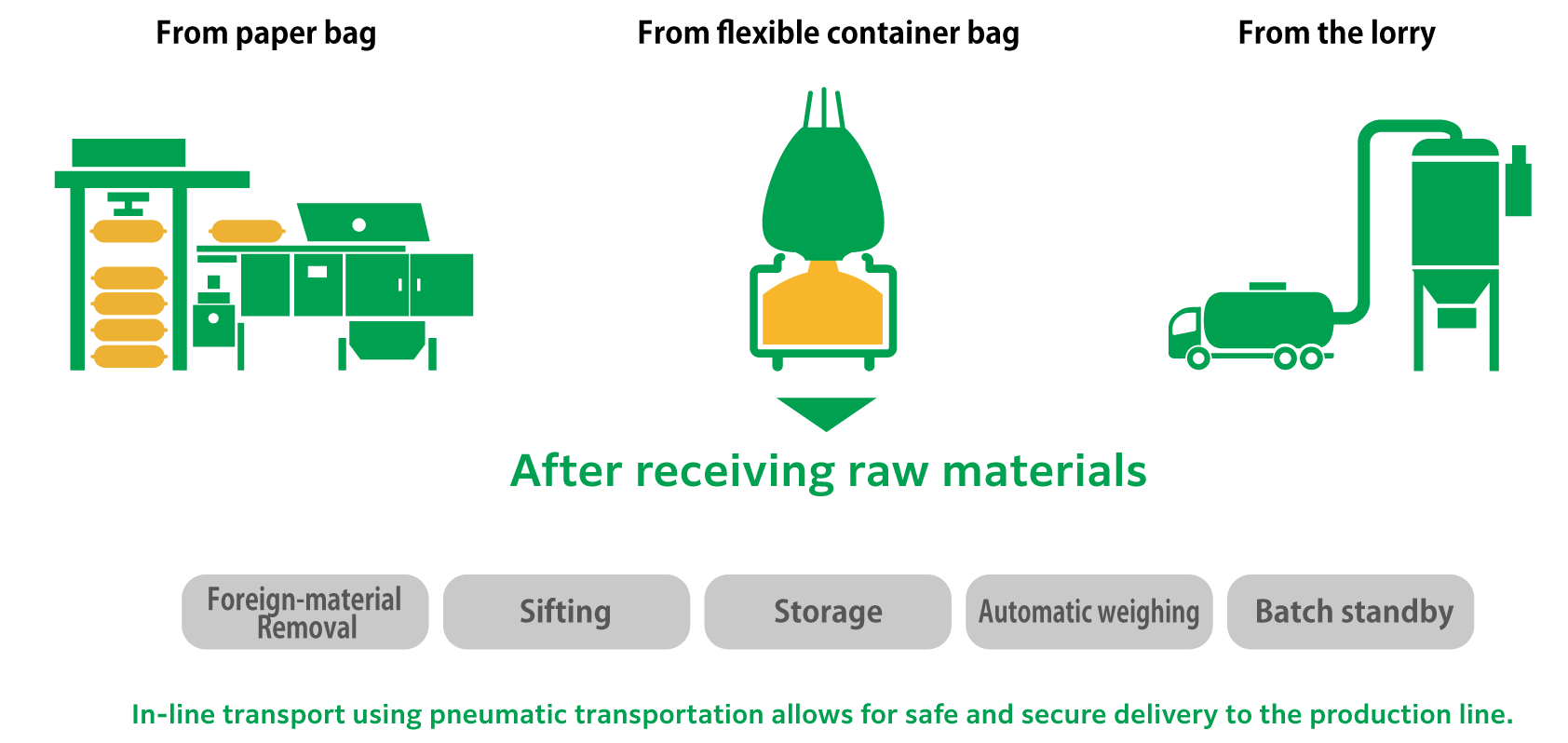

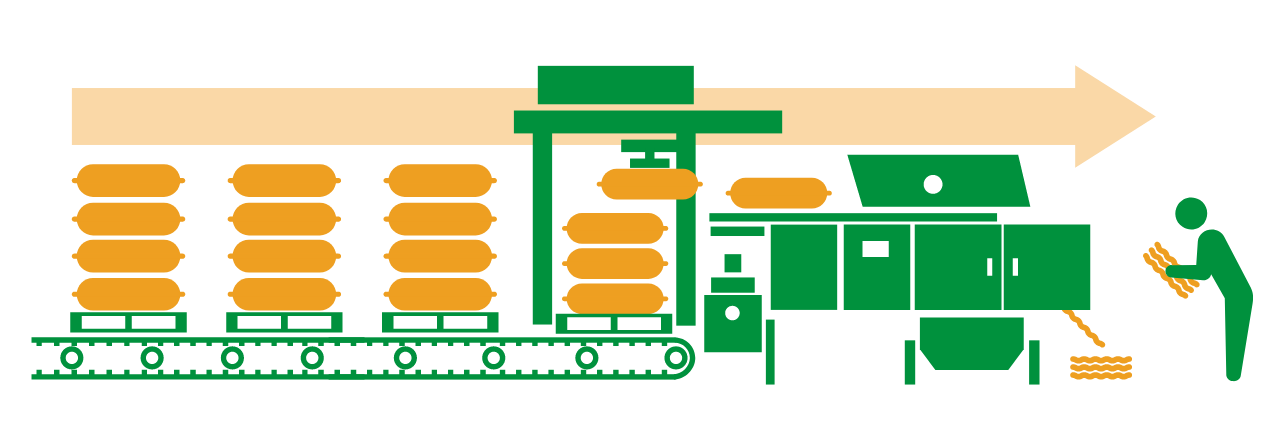

Material Receiving and Powder Feeding Process

Efficiently receive raw materials.

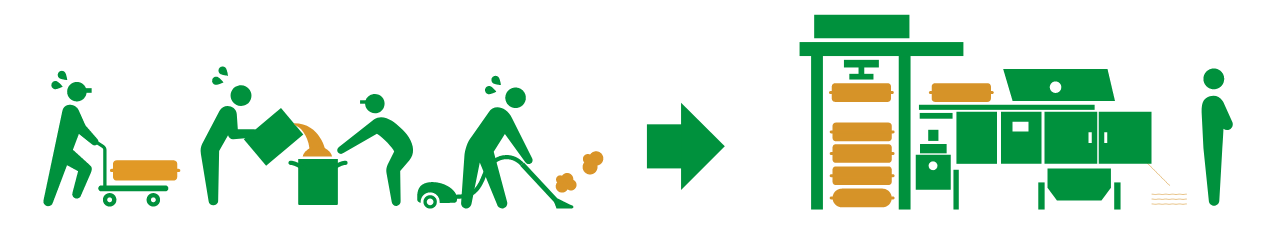

Workload of opening the bag is greatly reduced.

Making efficient receipt of raw materials according to the form of arrival. "Heavy labor when opening the bag" is eliminated, and it can be made inline by pneumatic transport without dust scattering until batch waiting just before the production line.

Receiving of powder raw materials

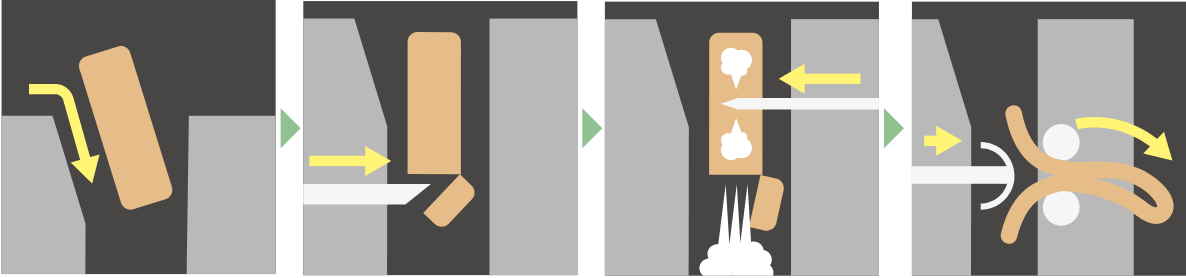

Application examples of TSUKASA's bag opening system 1

Automated bag opening now possible Saving 4 hours per person per day

At one factory, one worker was engaged in the opening of 20 kg per bag x 400 bags every day. It took about 30 seconds to open one bag, and it took more than 4 hours every day, including breaks and cleaning. With the introduction of the automatic bag-opening system, manual work became only stacking of bags on a pallet and replace them. Since it does not pollute the working environment, cleaning time is reduced, and the entire four hours could be allocated to other tasks.

Application examples of TSUKASA's bag opening system 2

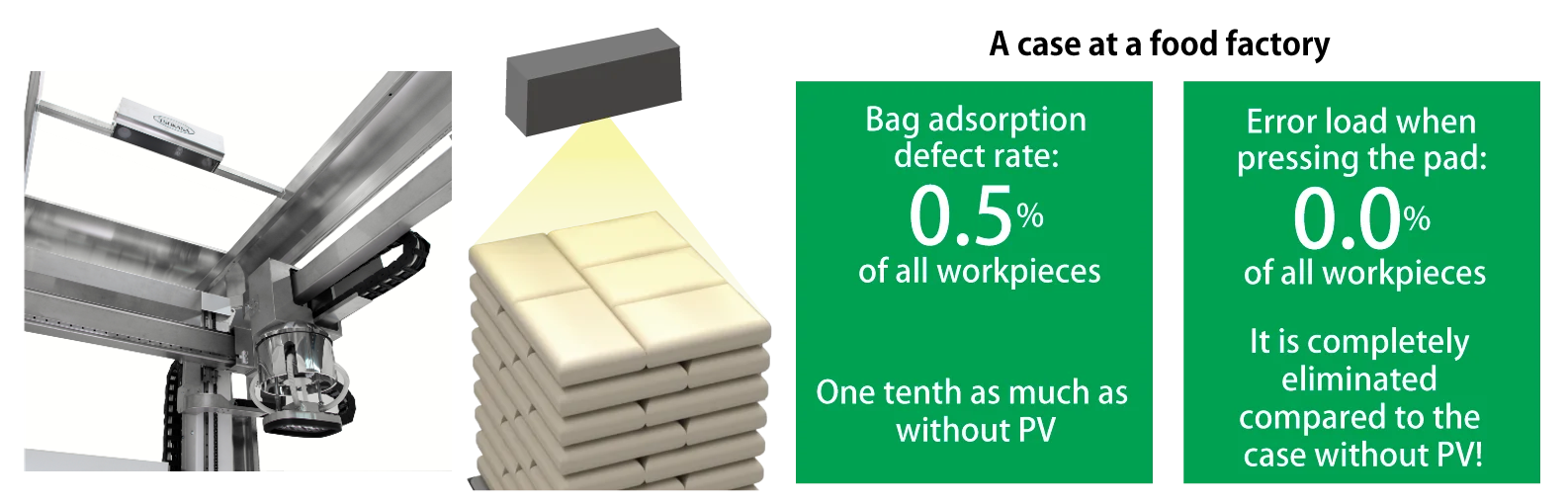

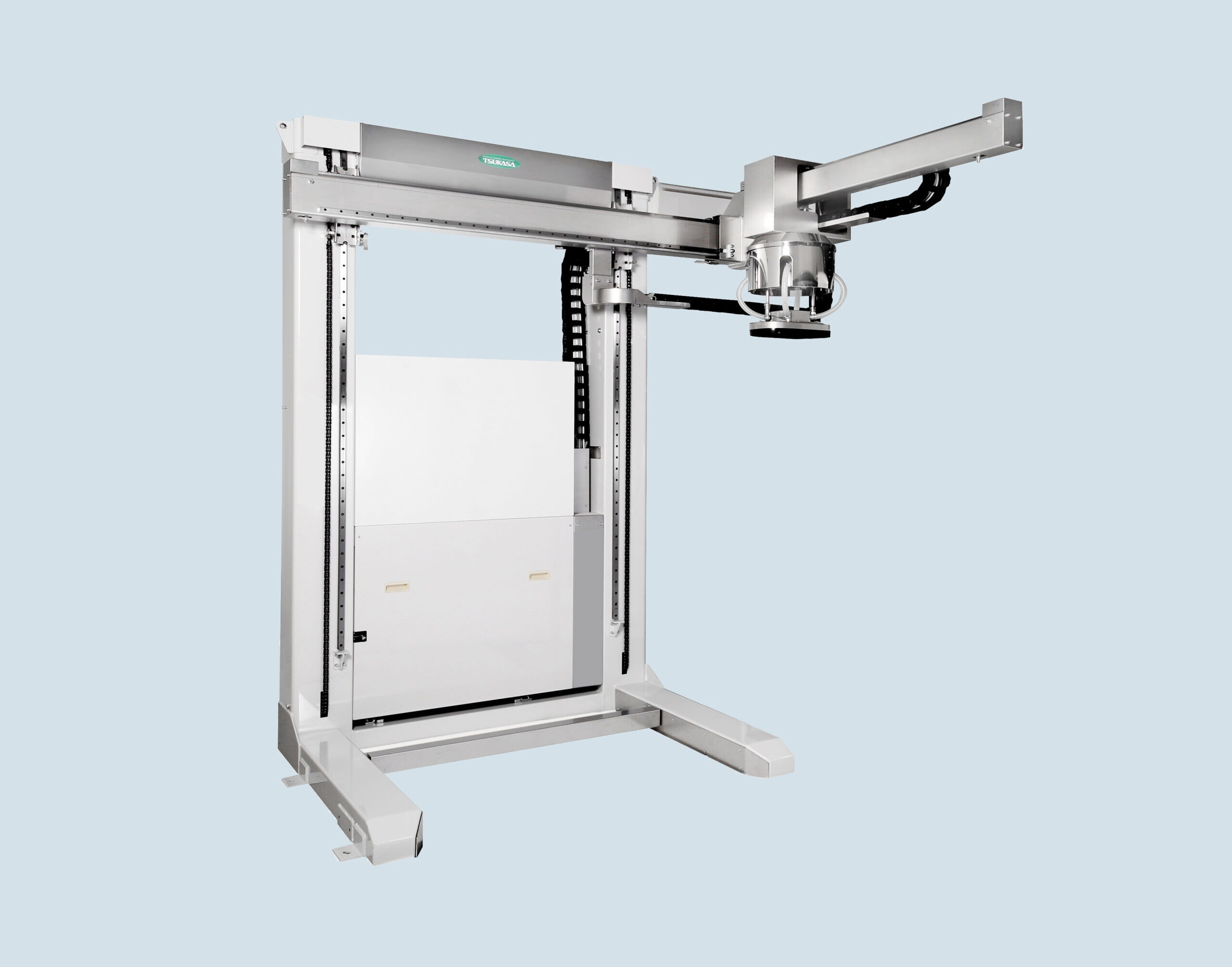

“Depalletizer Robo PV” Promote zero defect

During supplying raw material bags to the automatic opening system, the position, height and orientation of the bags on a pallet are accurately recognized by the 3D vision camera. "The problem of defective adsorption of the bag being less than 0.5% of the total," and "No error in load when pressing the pads" were achieved.

Application examples of TSUKASA's bag opening system 3

A start-up of a new factory using an automated warehouse system

For constructing the new plant, we studied how to enhance the overall efficiency of the operation. In order to completely eliminate manual work, the "automatic bag opening system" and "automatic warehouse system" have been linked.

Since "the next bag to be opened" is automatically transported at the right time, loading on the pallet and replacement work became unnecessary. The only human task is to visually check whether "the pallet transported is correct" and to handle the empty bag.

Since "the next bag to be opened" is automatically transported at the right time, loading on the pallet and replacement work became unnecessary. The only human task is to visually check whether "the pallet transported is correct" and to handle the empty bag.

Video

Special Specifications

large bag specification

⚫︎Accommodates larger bag sizes than usual

⚫︎Adaptable bag dimentions W550 x L1000 x H200mm

⚫︎Adaptable bag dimentions W550 x L1000 x H200mm

Articulated robot specification

⚫︎Transport raw materials from multiple pallets

Explosion-proof specification

⚫︎Specifications that do not allow electronic components or in-equipment wiring to be the source of ignition

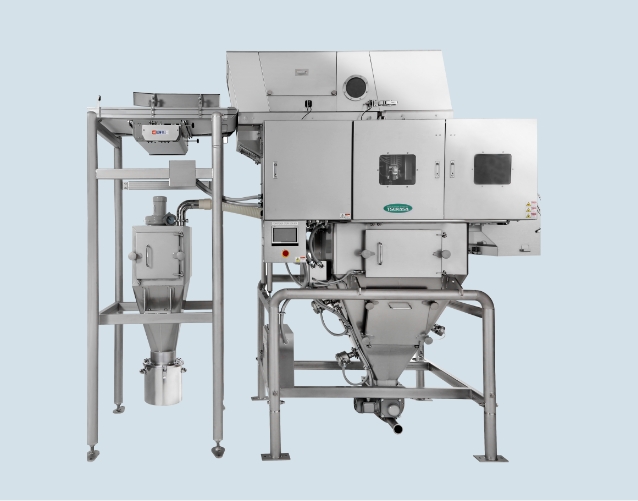

Automatic bag opening System

Automatic bag opening System

A system equipped with functions for bag supply, surface cleaning, and bag openingMORE >

Depalletizer robo(DPL)

An automated conveyor system equipped with a special suction mechanism and Cartesian coordinate drive for fast bag supply.MORE >

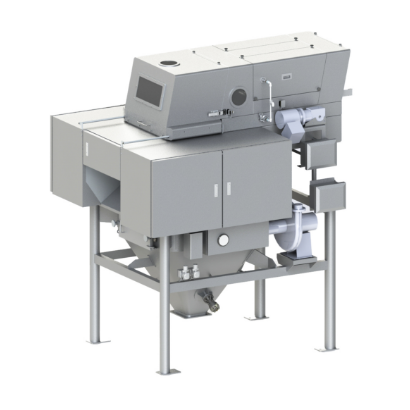

PowOpener(PO)

Compact automatic bag-opening equipment you can place anywhereMORE >

PowOpener Disassembly Washing Type(PO-WR)

An automatic bag opener designed for frequent cleaning during raw material switchingMORE >

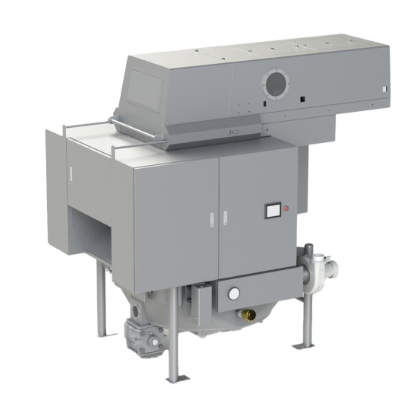

Pow Breaker(Solidified powder crusher)

A solidified powder crusher that eliminates bag opening problems with automatic bag openersMORE >

Raw material receiving equipment for flexible containers

FleconOpener Stock Model(FO-TF)

Bag-opening equipment for flexible container bags which can deal with powder that easily scattersMORE >

FleconOpener Compact Hopper Model(FO-SH)

A raw material receiving equipment for flexible containers, compatible with granular materials such as granulated sugar and refined salt.MORE >

Manual in-feed equipment

Dumping Server Conical Model(DSV-CF-300)

For this manual in-feed equipment, we painstakingly designed the height of the in-feed port, and reduced the burden on material feedingMORE >

Dumping Server and LINESIFTER Integrated Model(DSV-LS-25/50-300)

Manual in-feed equipment that is capable of simultaneously removing foreign materials and breaking down clumps in raw materials.MORE >

Dumping Server and LINESIFTER Integrated Model Hopper Type(DSV-LS-25/50-HP)

Manual in-feed equipment that is capable of simultaneously removing foreign materials and breaking down clumps in raw materials.MORE >

Dumping Server Premixing Model(DSV-PM)

A manual in-feed unit featuring a unique mixing paddle design that enables premixing of raw materialsMORE >

Dumping Server Hopper Model(DSV-S)

Manual in-feed equipment that is compact and can be installed in a limited spaceMORE >

If you want to request or download detailed information, or consult with us about technologies or ask questions about our products, contact us from this page.