Weighing Process

Precisely weight large amount of main materials and small amount of additives

Precisely weight large amount of main materials and small amount of additives

Weighing equipment

Divider Scale Receiver Model(DSC-RC)

Weighing equipment which stocks and automatically supplies materials conveyed with air

Features

⚫︎Automatic dividing and subdivision weighing equipment with integrated sifter

⚫︎Receiver storage tank has built-in dust collector and it supplies materials by pneumatic transportation.

⚫︎Receiver storage tank capacity is optional (standard is 150liter).

⚫︎Receiver storage tank is selectable from table feeder Type and hopper Type.

⚫︎While weighing, sifting and magnetic material removal operations are also carried out.

⚫︎Built-in dust collector also collects dust generated during automatic weighing. Thus collected powder will be reused.

⚫︎Rule of thumb for measurement is 2 to 20kg and standard minimal scale is 0.02kg.

⚫︎Disassembly and cleaning are easy.

⚫︎Receiver storage tank has built-in dust collector and it supplies materials by pneumatic transportation.

⚫︎Receiver storage tank capacity is optional (standard is 150liter).

⚫︎Receiver storage tank is selectable from table feeder Type and hopper Type.

⚫︎While weighing, sifting and magnetic material removal operations are also carried out.

⚫︎Built-in dust collector also collects dust generated during automatic weighing. Thus collected powder will be reused.

⚫︎Rule of thumb for measurement is 2 to 20kg and standard minimal scale is 0.02kg.

⚫︎Disassembly and cleaning are easy.

Specifications

⚫︎Material stocker: 50〜500ℓ

⚫︎Weighing range: 1kg to 20kg (Apparent specific gravity of 0.5)

⚫︎Minimum scale: 10g

⚫︎Scaling accuracy: ±50g or ±5g ※option

⚫︎Weighing range: 1kg to 20kg (Apparent specific gravity of 0.5)

⚫︎Minimum scale: 10g

⚫︎Scaling accuracy: ±50g or ±5g ※option

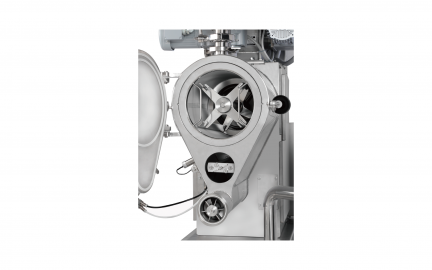

Inside of Table feeder Type

Various functions in one piece of equipment