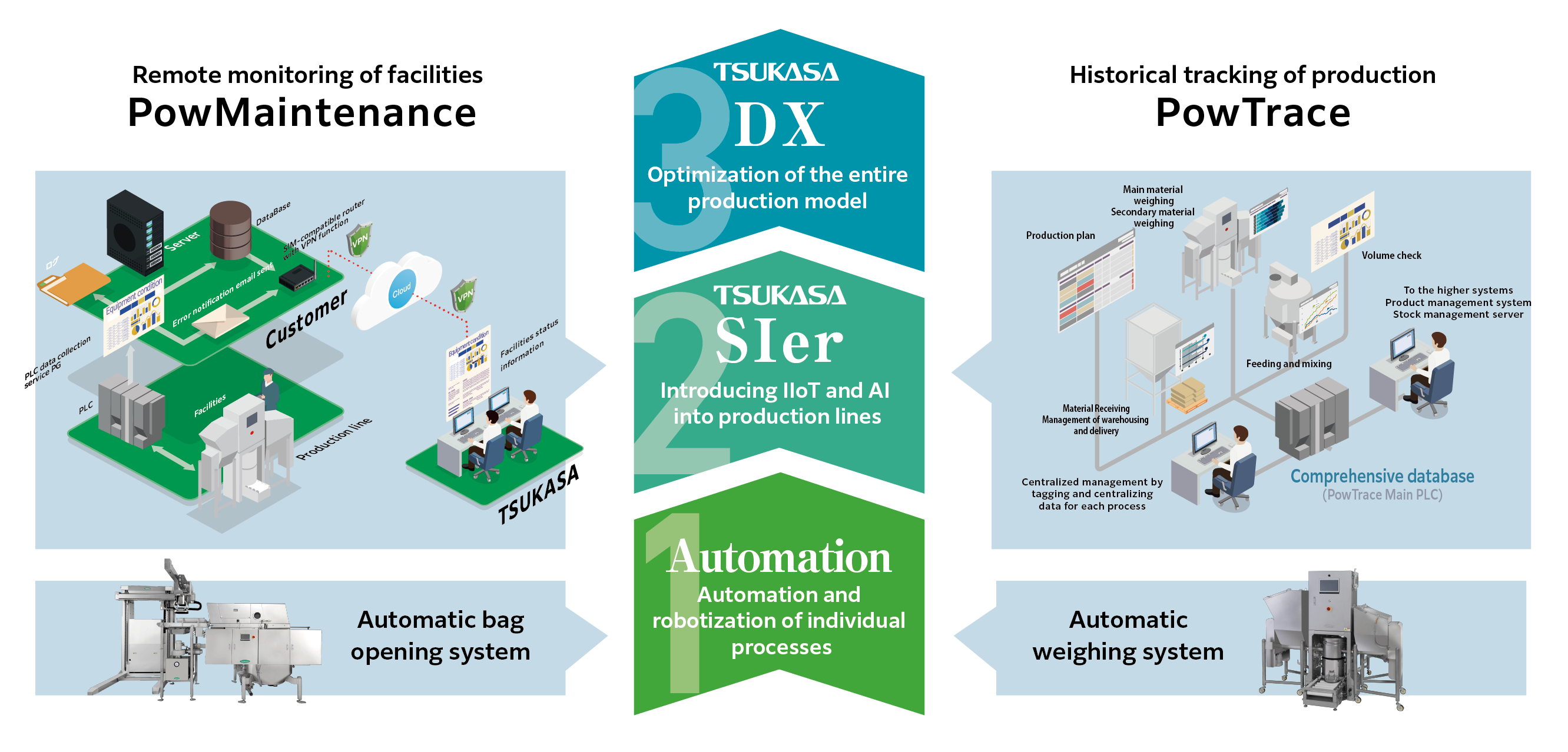

TSUKASA DX【Three stages of evolution】

Present, near future, and to a new era.

We will steadily promote DX initiatives.

TSUKASA has a system in place where you can entrust us with a consistent approach from consulting to system design, operation support, and data analysis for the digitalization of your plant. We have dedicated departments and staff in the company, and we aim to put new ideas into practical use every day to improve the productivity of our customers.

DX Evolution Theory

"Three stages of digitalization" and "TSUKASA's initiatives"

evolution.1

Automation and robotization of individual processes

TSUKASA's initiatives

Automating and robotizing tasks such as opening and weighing raw material bags, traditionally performed by humans. By digitizing and storing operational data, it can be utilized for subsequent management tasks (such as tracking stock levels). Significant improvements in work efficiency and personnel reduction can also be expected.

evolution.2

Introducing IIoT and AI to the production line

TSUKASA's initiatives

Typical examples are the remote monitoring system "PowMaintenance" at factories and the "PowTrace" that can track production history. By digitalizing the entire production line, we aim to achieve "total optimization" by organically connecting everything from receiving and supplying raw materials to weighing and mixing them.

evolution.3

Optimization of the entire production model

TSUKASA's initiatives

Through the linkage of TSUKASA's "automatic bag opening system" and the "automatic warehouse system," etc., we will optimize the entire production model of the plant, not just the "powder" category, and we will also consider contributing to the overall marketing of our customers' products.