Material Receiving and Powder Feeding Process

Achieved Speedy and efficient reception and supply of materials

Achieved Speedy and efficient reception and supply of materials

Automatic bag opening System

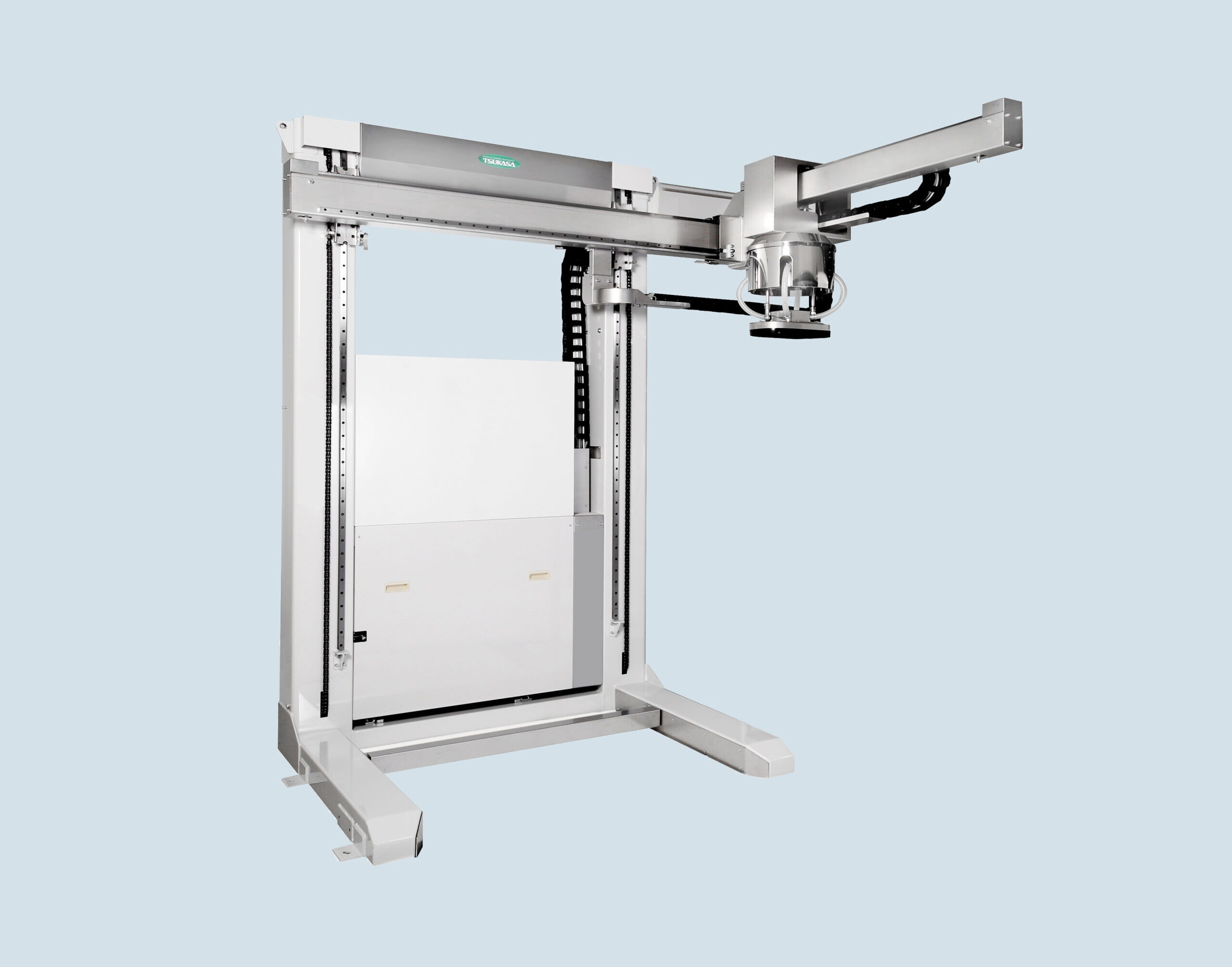

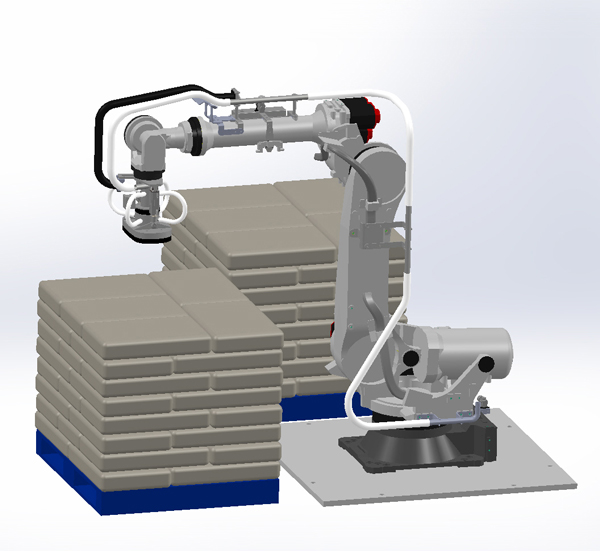

Depalletizer robo(DPL)

An automated conveyor system equipped with a special suction mechanism and Cartesian coordinate drive for fast bag supply.

Features

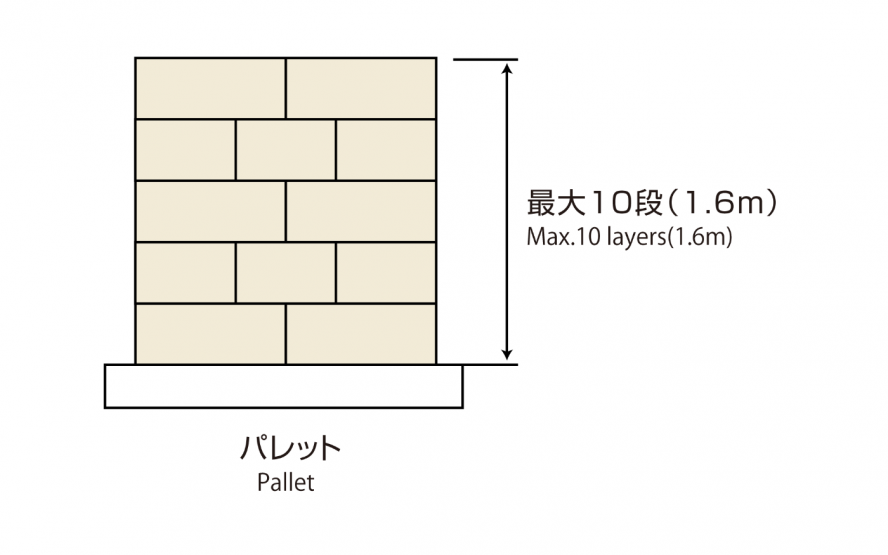

⚫︎Paper bags stacked on pallets are automatically conveyed to the next process using the special suction mechanism.

⚫︎The Cartesian-style arm operates safely within a single pallet’s range—maximizing safety and minimizing space requirements. Articulated robot models available for operations involving multiple pallets.

⚫︎Touch panel control allows easy registration and modification of pallet stacking patterns.

⚫︎The optional Depalletizer Robo PV, featuring advanced image recognition, accurately detects bag positions—no teaching required.

⚫︎The Cartesian-style arm operates safely within a single pallet’s range—maximizing safety and minimizing space requirements. Articulated robot models available for operations involving multiple pallets.

⚫︎Touch panel control allows easy registration and modification of pallet stacking patterns.

⚫︎The optional Depalletizer Robo PV, featuring advanced image recognition, accurately detects bag positions—no teaching required.

The example of installation

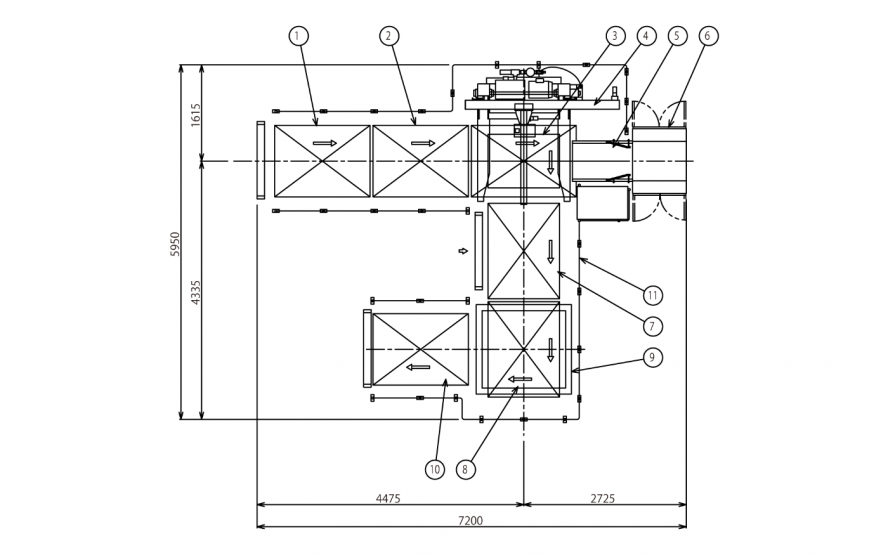

Opening of one type of bag continuously

1.Pallet conveyor

2.Pallet conveyor

3.Depalletizer orthogonal conveyor

4.Depalletizer

5.Inlet conveyor

6.PowOpener

7.Pallet conveyor

8.Conveyor for stocker

9.Pallet stocker

10.Pallet conveyor

11.Safety fence

2.Pallet conveyor

3.Depalletizer orthogonal conveyor

4.Depalletizer

5.Inlet conveyor

6.PowOpener

7.Pallet conveyor

8.Conveyor for stocker

9.Pallet stocker

10.Pallet conveyor

11.Safety fence

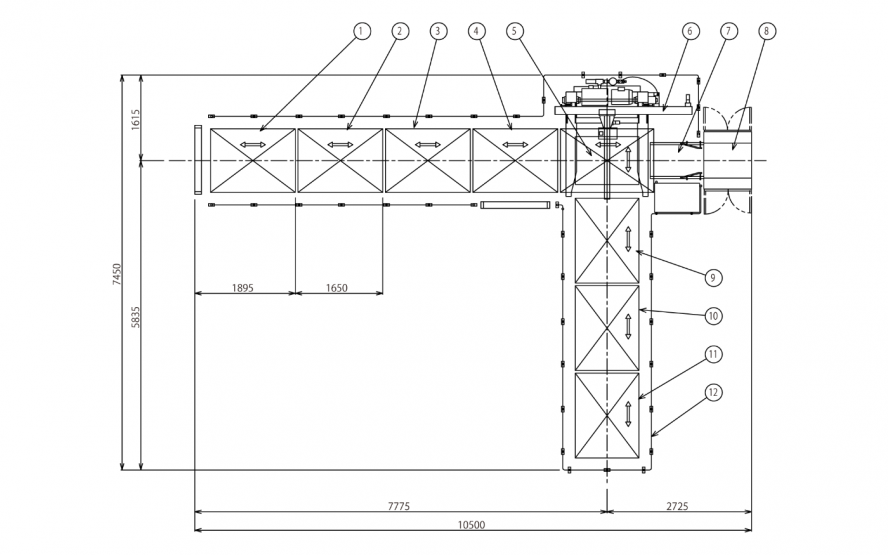

Opening of various type of bags

1.Pallet conveyor(Forward and reverse)

2.Pallet conveyor(Forward and reverse)

3.Pallet conveyor(Forward and reverse)

4.Pallet conveyor(Forward and reverse)

5.Depalletizer orthogonal conveyor

6.Depalletizer

7.Inlet conveyor

8.PowOpener

9.Pallet conveyor(Forward and reverse)

10.Pallet conveyor(Forward and reverse)

11.Pallet conveyor(Forward and reverse)

12.Safety fence

2.Pallet conveyor(Forward and reverse)

3.Pallet conveyor(Forward and reverse)

4.Pallet conveyor(Forward and reverse)

5.Depalletizer orthogonal conveyor

6.Depalletizer

7.Inlet conveyor

8.PowOpener

9.Pallet conveyor(Forward and reverse)

10.Pallet conveyor(Forward and reverse)

11.Pallet conveyor(Forward and reverse)

12.Safety fence

Special specifications

Articulated robot specification

⚫︎Articulated robot arm transports raw materials from multiple pallets.

⚫︎Responding to various layouts.

⚫︎Responding to various layouts.

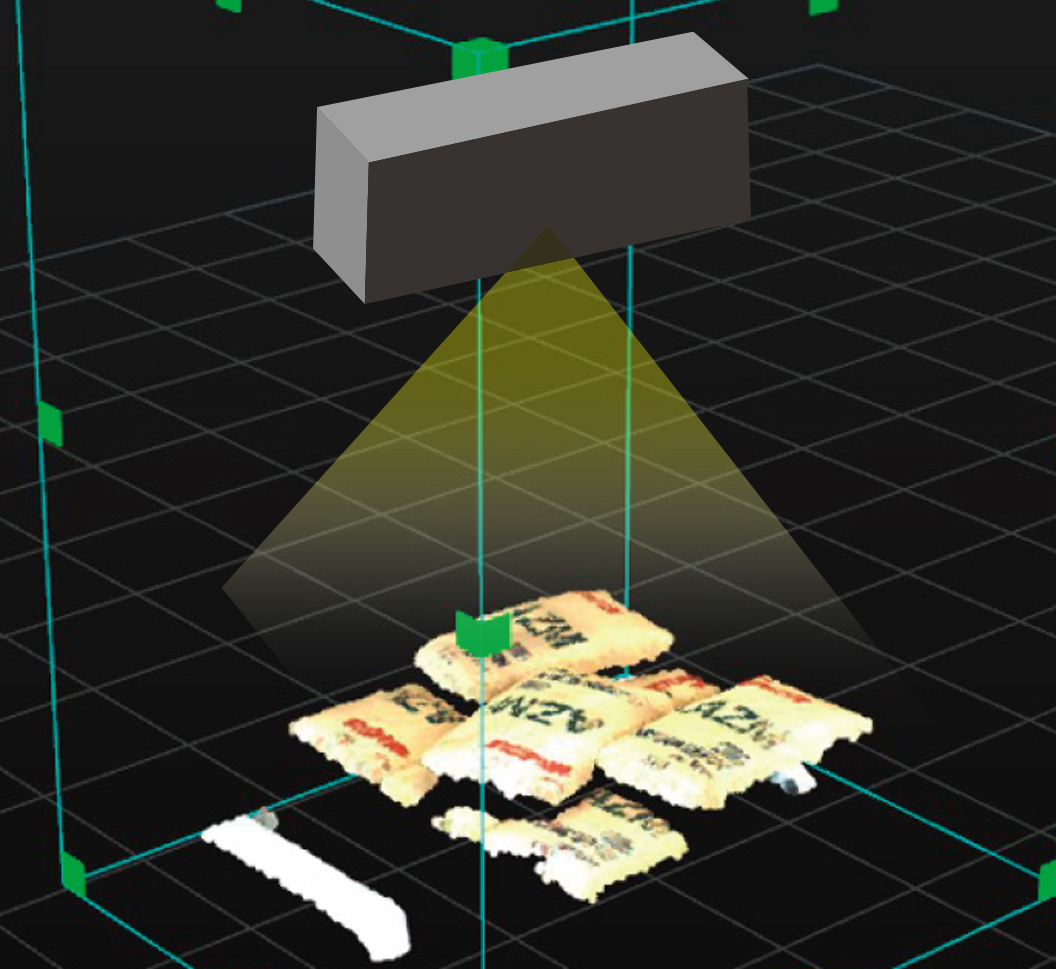

Depalletizer Robo PV(PowVision)

⚫︎During supplying raw material bags to the automatic opening system, the position, height and orientation of the bags on a pallet are accurately recognized by the 3D vision camera.

⚫︎No need for operators to stack bags or select patterns.

⚫︎No need for operators to stack bags or select patterns.