Weighing Process

Precisely weight large amount of main materials and small amount of additives

Precisely weight large amount of main materials and small amount of additives

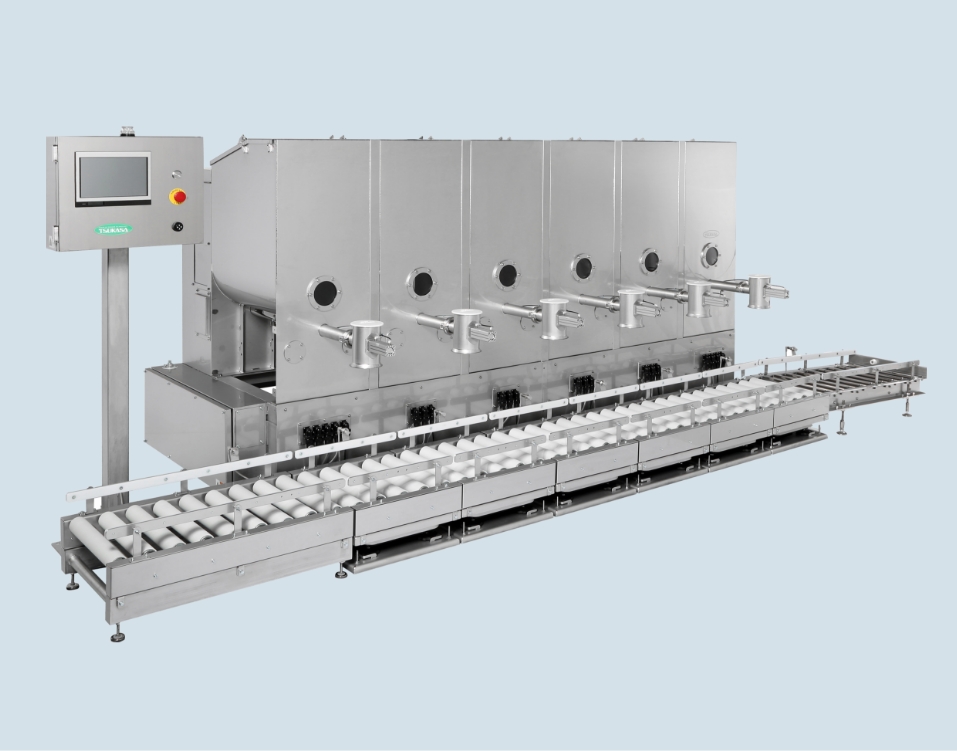

Weighing equipment

Divider Scale Combination Model(DSC-C)

Automatic dividing/weighing equipment which can automatically weigh a wide variety of materials

Features

⚫︎The small hybrid automatic weighing device which collected the dumping device and an automatic weighing unit all together.

⚫︎Appropriate for measuring and dividing supplemental material and additives.

⚫︎Structured with Stock hopper, Screw feeder, Container transfer conveyor, Load cell and Weighing/blending system.

⚫︎Scattering particulates are controlled with the dust collector (option) and dust collecting hood (standard equipment) at the time of weighing/filling.

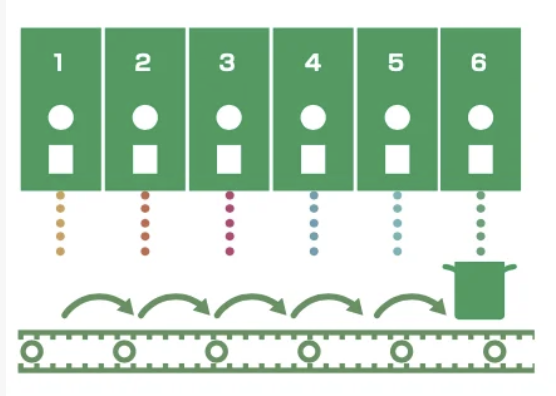

⚫︎Triple, sextuple and nonuple Stock hoppers are standardized to meet various applications.

⚫︎Powdered yolk or other materials of low fluidity can be handled.

⚫︎Easy to disassemble and water-washable.

⚫︎Appropriate for measuring and dividing supplemental material and additives.

⚫︎Structured with Stock hopper, Screw feeder, Container transfer conveyor, Load cell and Weighing/blending system.

⚫︎Scattering particulates are controlled with the dust collector (option) and dust collecting hood (standard equipment) at the time of weighing/filling.

⚫︎Triple, sextuple and nonuple Stock hoppers are standardized to meet various applications.

⚫︎Powdered yolk or other materials of low fluidity can be handled.

⚫︎Easy to disassemble and water-washable.

Applications

⚫︎For blending of materials of food products, chemical products, etc.

⚫︎For blending food products, chemical products, etc.

⚫︎For blending food products, chemical products, etc.

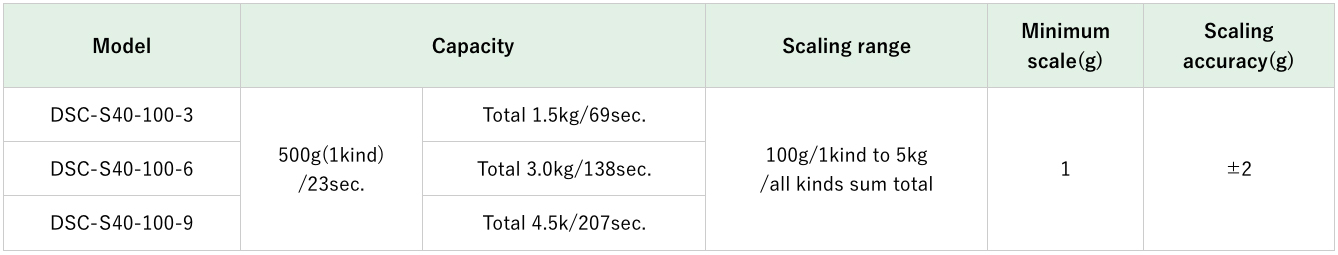

※Above capacity is in the case of extra-strenght flour, apparent specific gravity of 0.5. Capacity may vary according to usage connditions.

※Consult us about performance, weighing range, weighing accuracy and the number of combined hoppers.

※Consult us about performance, weighing range, weighing accuracy and the number of combined hoppers.