Drying and Controlling Temperature Process

Drying and temperature adjustment for stable quality throughout the year

Drying and temperature adjustment for stable quality throughout the year

Powder temperature adjustment equipment

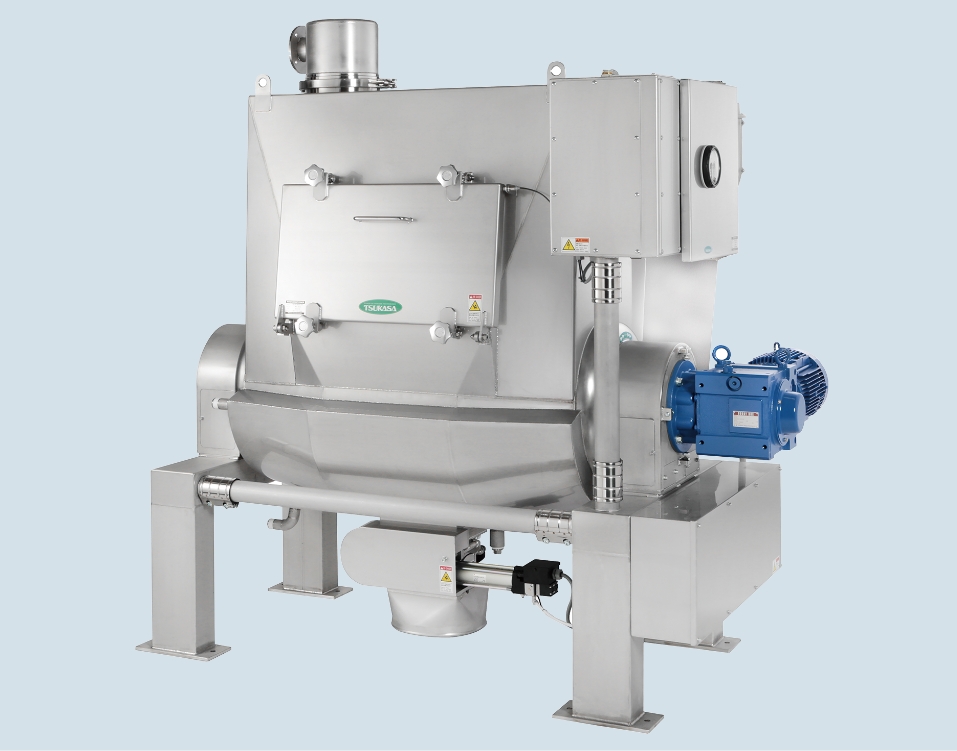

PowConditioner

Powder temperature adjusters that can premix raw materials at the same time as heating or cooling

Features

⚫︎Powder material temperature adjustment device

⚫︎The unique conical casing and mixing blades fluidize raw materials, enabling rapid and efficient cooling in summer and heating in winter.

⚫︎More effective temperature control is possible by combining the air mixing method, which sends cold or hot air into the unit, and the jacket method, which adjusts the temperature of the casing using cold or hot water.

⚫︎Almost no change is caused to water content of flour etc. by cooling and warming.

⚫︎Mixing mechanism enables pre-mixing of raw material simultaneously with temperature adjustment.

⚫︎The unique conical casing and mixing blades fluidize raw materials, enabling rapid and efficient cooling in summer and heating in winter.

⚫︎More effective temperature control is possible by combining the air mixing method, which sends cold or hot air into the unit, and the jacket method, which adjusts the temperature of the casing using cold or hot water.

⚫︎Almost no change is caused to water content of flour etc. by cooling and warming.

⚫︎Mixing mechanism enables pre-mixing of raw material simultaneously with temperature adjustment.