Products

Wrong feeding prevention system

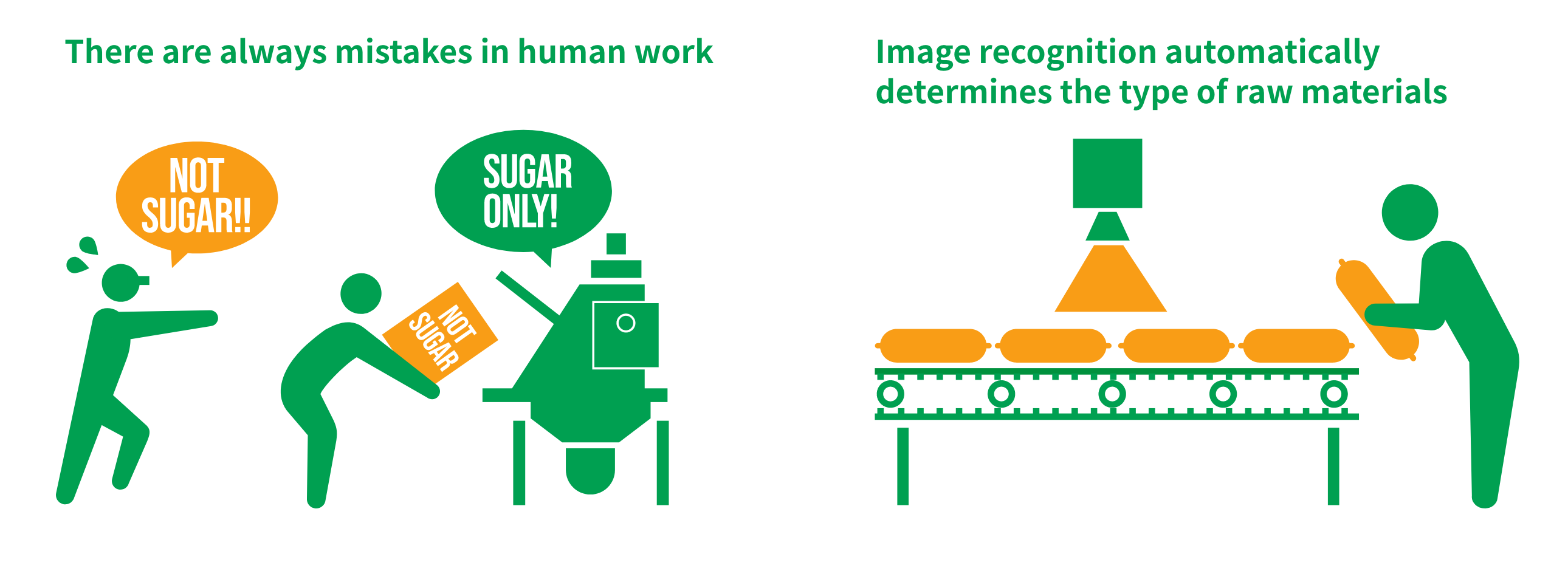

Image recognition ensures that human error

during raw material feeding is prevented.

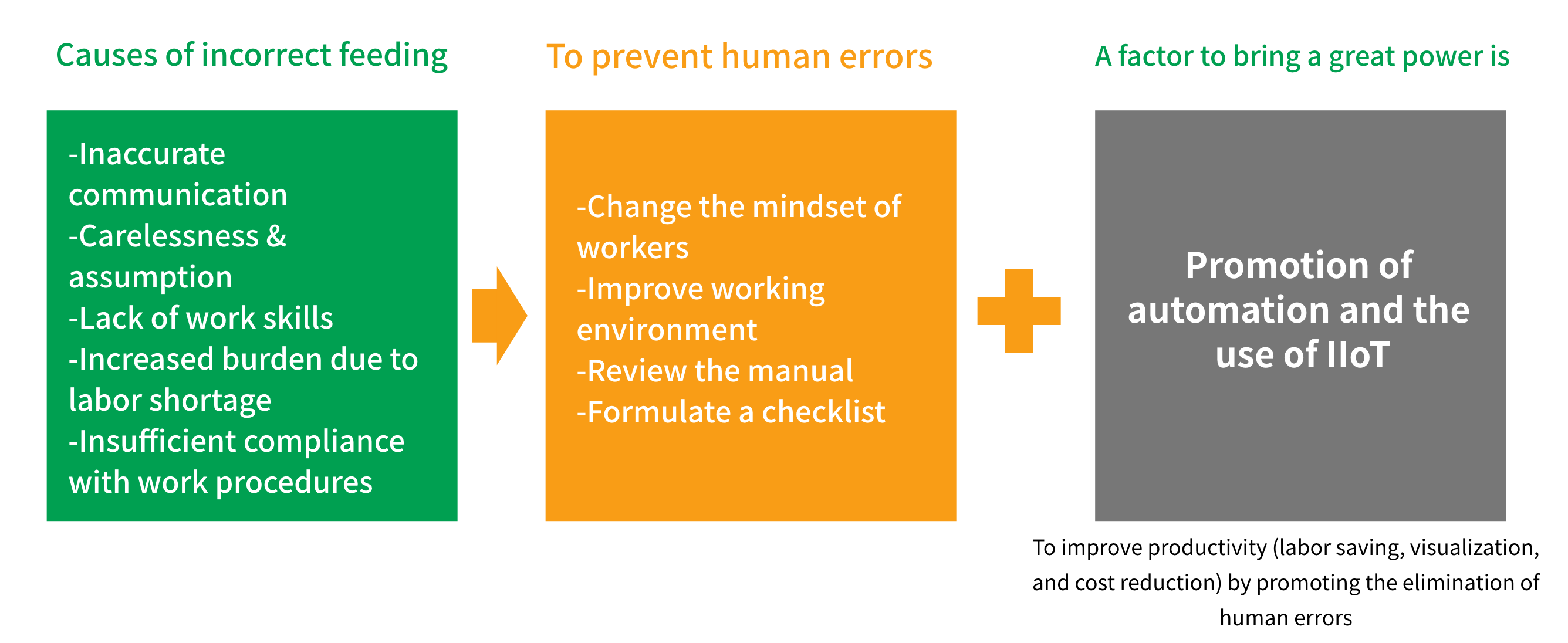

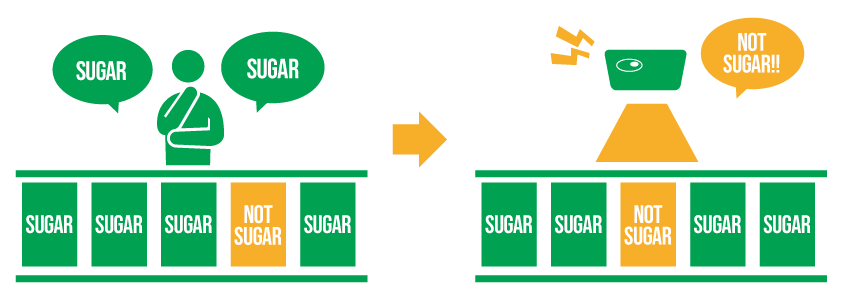

Sites that handle many types of powder materials, preventing incorrect feeding due to operator check errors is also a major issue. Therefore, we have prepared a system that recognizes letters and patterns on the surface of the raw material bag and supplies them to the equipment only when the "OK" signal is received.

Application example of TSUKASA's wrong feeding prevention system in use

Mishandling of raw ingredients (flour, sugar, additives, etc.) as they were added, was a common problem when feeding. With the introduction of the "PV Checker", we were able to shut out erroneous input by photographing the surface of the bag before injection, and only unlocking the injection door when the design (letters, patterns, colors, etc.) was deemed "OK".

If you want to request or download detailed information, or consult with us about technologies or ask questions about our products, contact us from this page.