Sifting and Foreign-material Removal Process

Performs efficient sieving and foreign material removal

Performs efficient sieving and foreign material removal

Sifter

PowSifter︎ Three sized classify Model(PSF-SPW)

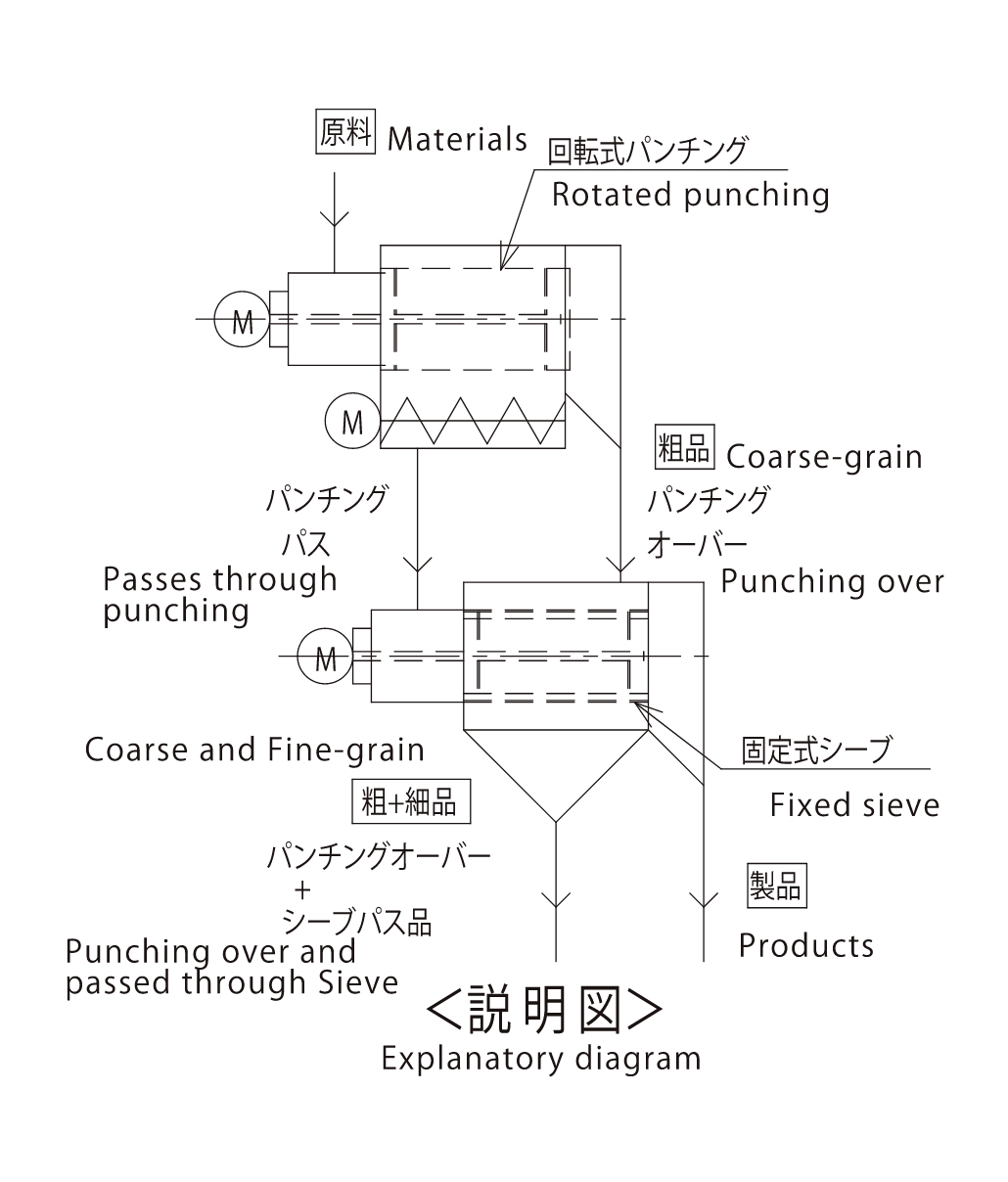

In-line model sifter which is installed in the chute conveyance line for classifying materials into three particle size

Features

⚫︎Features a cylindrical structure and high-speed rotating beater for sifting raw materials.

⚫︎Appropriate for removing fine or over-size particle from granulated material.

⚫︎Two PowSifters stacked vertically saves installation space.

⚫︎Screw Feeder incorporated in the first stage sifter feeds a given quantity of passed material to the second sifter, enabling stable sifting.

⚫︎Easy inspection and replacement of the sieve.

⚫︎The super-low-pitched sound design with very little vibration.

⚫︎Appropriate for removing fine or over-size particle from granulated material.

⚫︎Two PowSifters stacked vertically saves installation space.

⚫︎Screw Feeder incorporated in the first stage sifter feeds a given quantity of passed material to the second sifter, enabling stable sifting.

⚫︎Easy inspection and replacement of the sieve.

⚫︎The super-low-pitched sound design with very little vibration.

Options

⚫︎Water-washable design