Products

Mixing Process

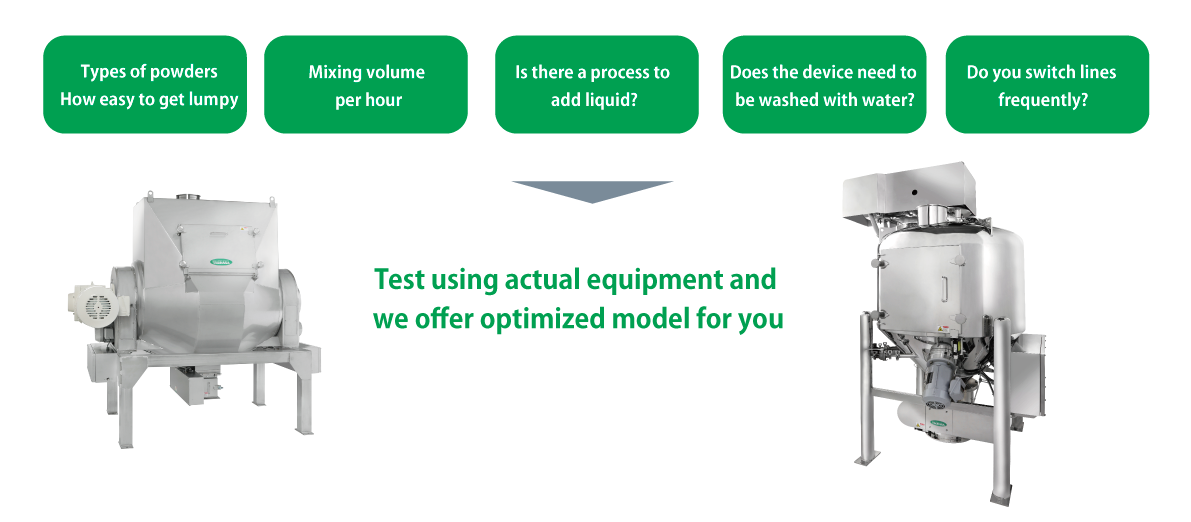

A lineup of equipment that can be applied

attentively to various mixing conditions.

We offer mixers and options that can flexibly handle the type of powder of your choice and the environment at the production site.

We are able to meet your needs of "Can we mix in these conditions" in various industrial fields such as food, chemicals, pharmaceuticals, and electronics in detail.

Abundant know-how and experience in mixing machines that take advantage of the characteristics of the cone shape. *Shaft rotating type

Even mixing in a short time

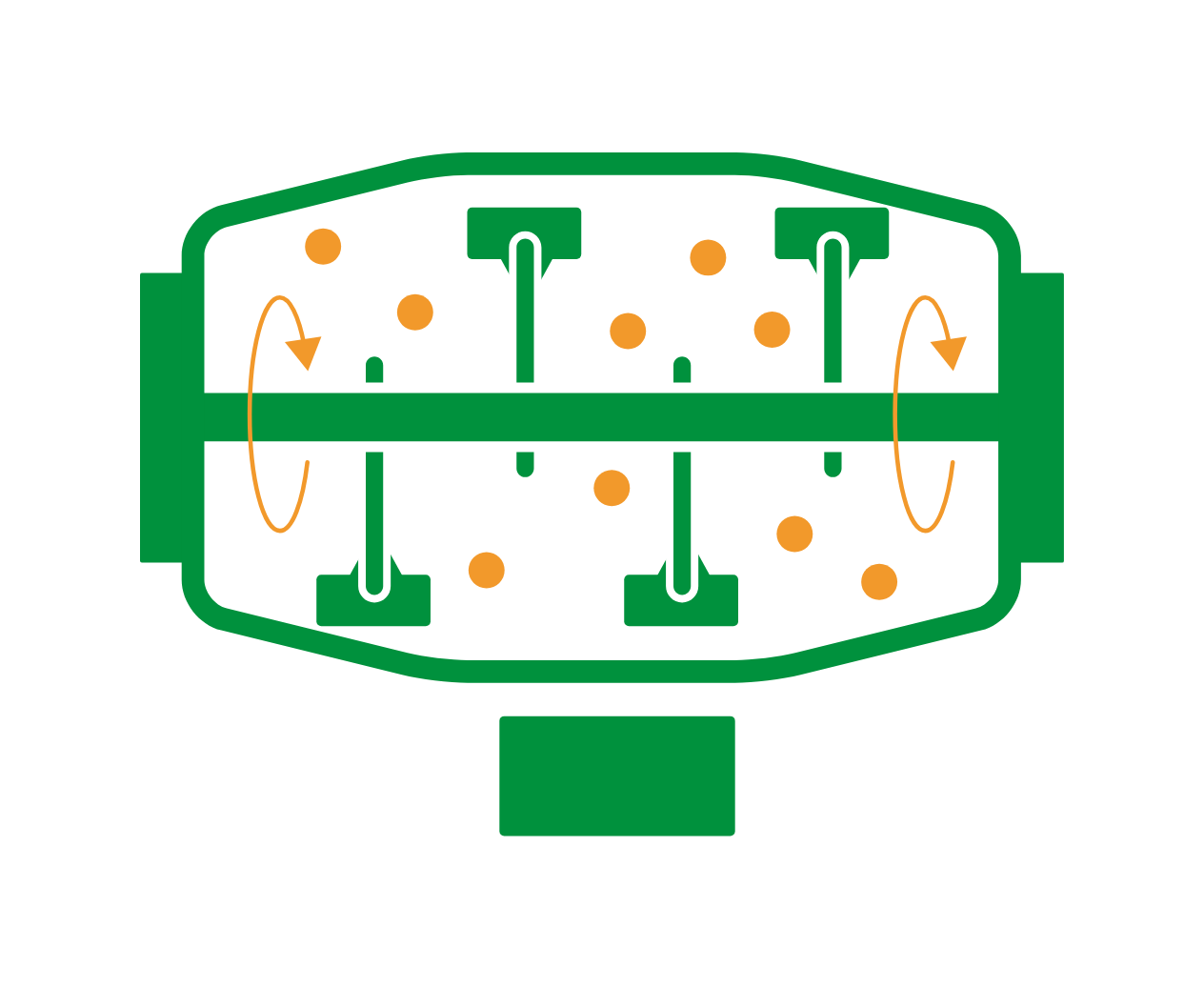

⚫︎PowMixer Conical & Horizontal Model

Three-dimensional mixing flow is created completely inside the mixer, and materials with large specific gravity and particle size differences can be mixed evenly in a short time.

Excellent cleaning and discharge functions

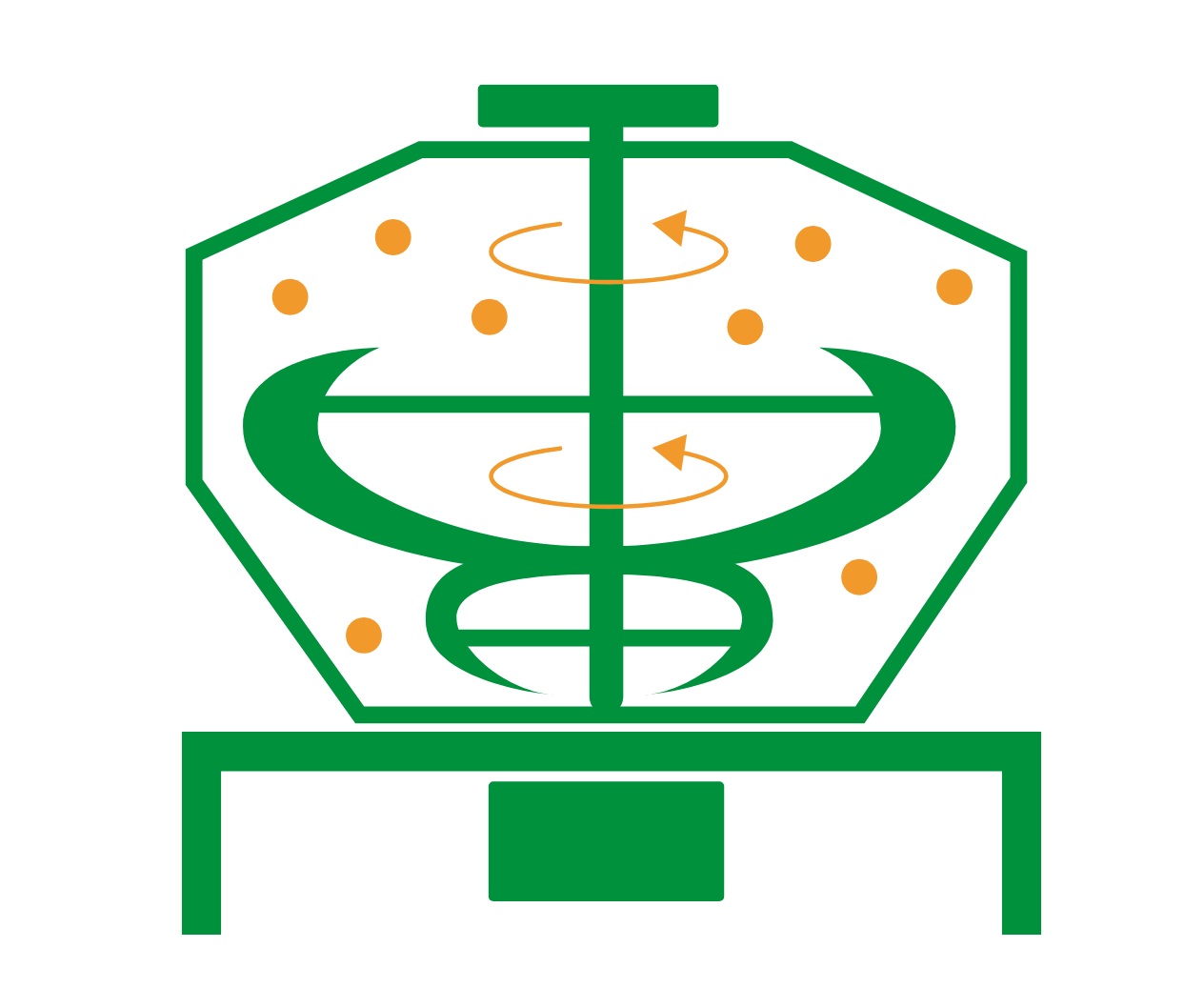

⚫︎PowMixer Conical & Vertical Model

Excellent in discharging of raw materials, and little residue in the main unit. The spiral blade by our original development creates a complex mixing flow that allows soft mixing of powders and liquids.

TSUKASA Mixing Module

Compactly and automatically complete everything from feeding powder raw material, collecting dust, removing foreign matters, sieving, mixing, stocking and weighing. It ensures an effective use of factory space.

The point of powder mixing

Application examples of TSUKASA's mixing equipment 1

Mixing time of powder raw materials Reduced to 5 minutes from 15 minutes

One factory used a screw-type mixer for many years. In order to further improve productivity, they tried to upgrade equipment, and at the site where the mixing time was set to 15 minutes with the conventional equipment, the mixing time was reduced to 5 minutes by introducing the "PowMixer Conical Vertical Type".

Application examples of TSUKASA's mixing equipment 2

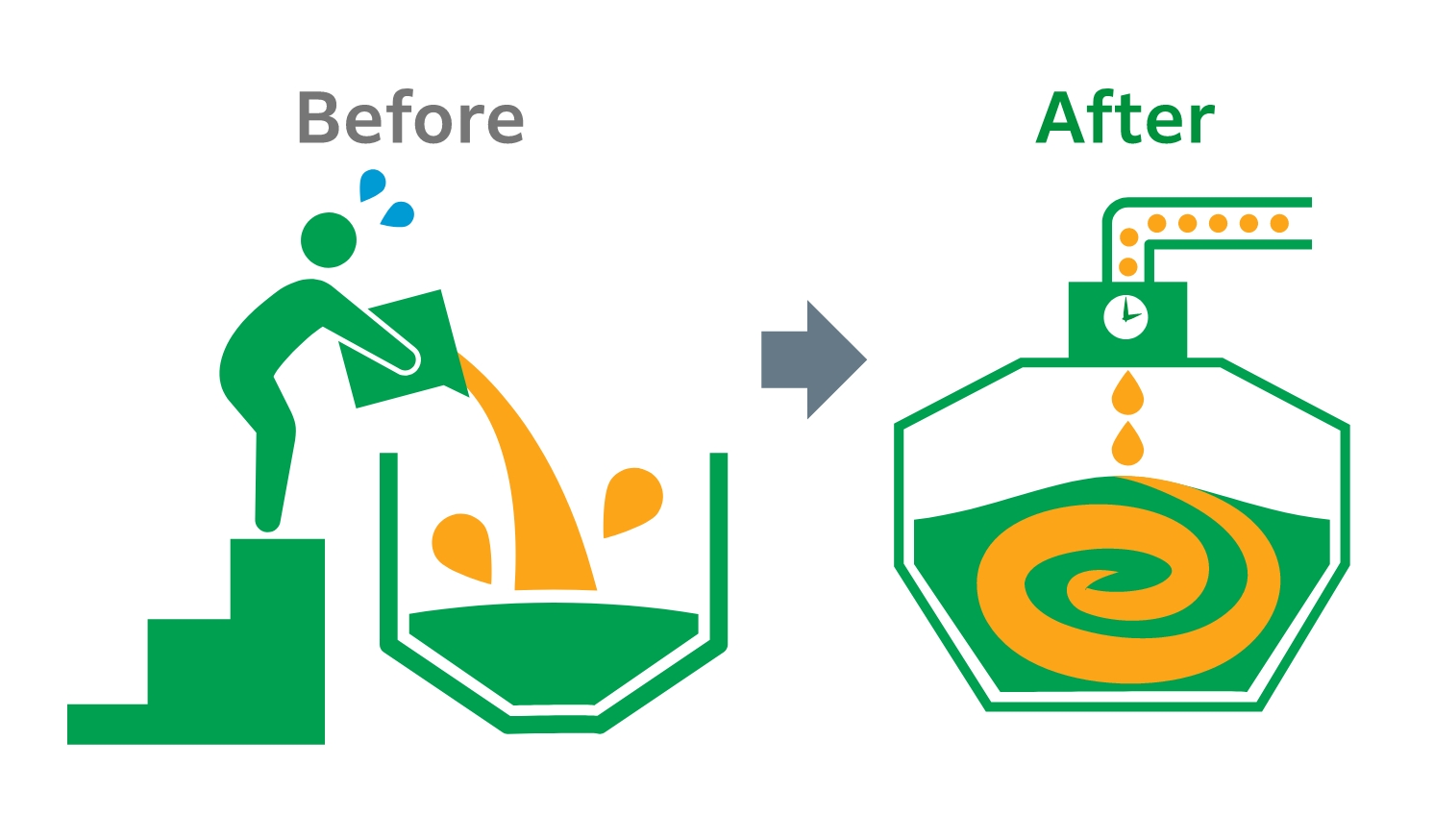

Adding liquid is automated Also making maintenance easy

It enabled to wash automatically with water into the main unit. Compared to so-called "powder washing", there is almost no need to worry about unwashed items, and there it eliminated an operation by workers to go inside the mixer to wash.

They introduced the "PowMixer Conical Vertical Type," which softly mixes powder and liquid, and a liquid adding device (optional). The automatic addition of water and oil eliminated the workload of "manually pouring liquid over powder".

Video

Mixer

-

PowMixer Conical & Horizontal Model(PM-CH)

A horizontal mixer with a unique paddle design enables high-efficiency, high-precision mixing in short cyclesMORE > -

PowMixer Conical & Vertical Model(PM-CV)

A vertical mixer equipped with original spiral blades for high-precision mixing in a short time, with excellent cleanabilityMORE > -

PowMixer Cross-rotary Model(PM-CM)

Mixer with for dispersion and uniform mixing of small and very small quantitiesMORE > -

PowMixer Cross-rotary Model Laboratory Specifications(CM-3)

Small cross rotary mixer suitable for experiments and researchMORE > -

Batter Mixer (BT)

Batter manufacturing mixer for mixing powder in liquidMORE >

If you want to request or download detailed information, or consult with us about technologies or ask questions about our products, contact us from this page.