Products

PowTrace

Ensuring traceability.

You can reliably track down the cause of the trouble.

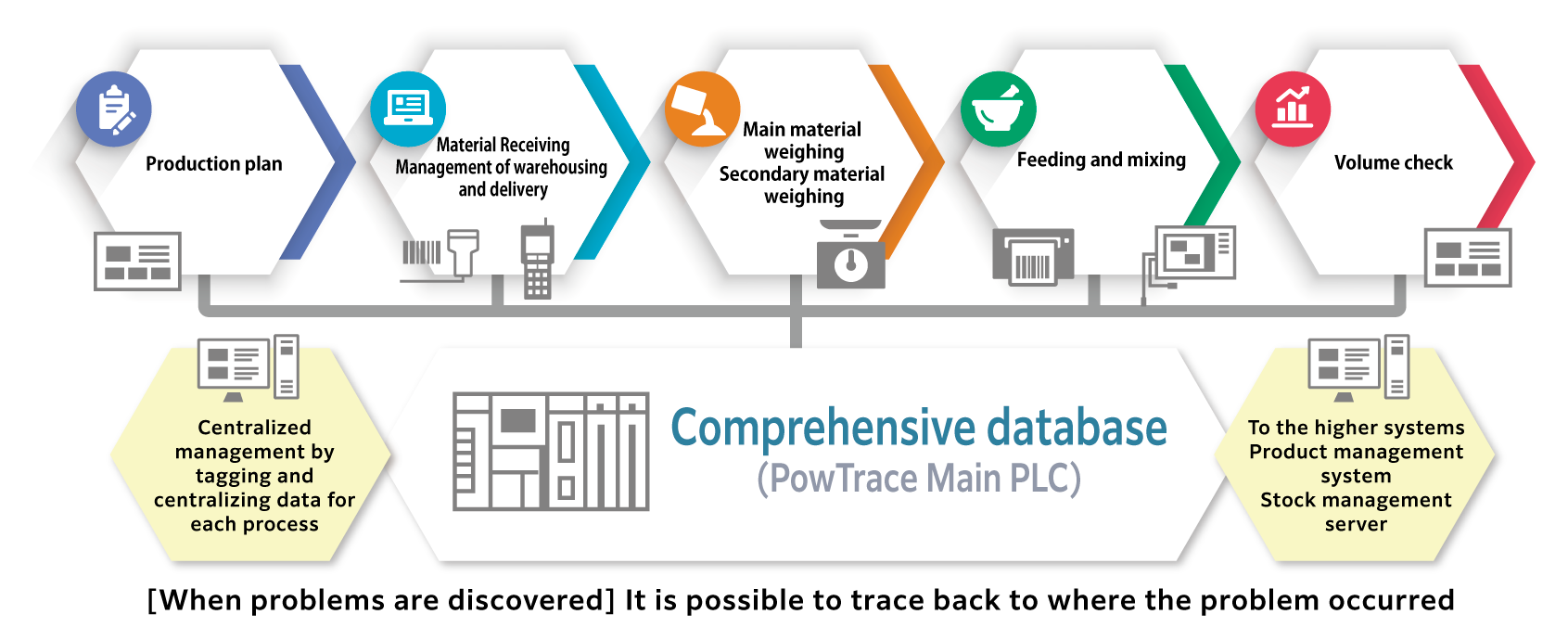

Recording the work history of each process to be managed collectively in the higher-level system

"PowTrace" is a system that centrally manages work data for each process, from receiving powder raw materials to weighing and mixing, and can track "where the problem occurred" when a problem is detected.

If production facilities are centrally controlled, it is also possible to link with a higher-level production management system. For example, it is possible to receive instructions (what and how much) on weighing content from the higher-level system, and to send back the work data on the weighing machine to the higher-level to centrally manage it.

If production facilities are centrally controlled, it is also possible to link with a higher-level production management system. For example, it is possible to receive instructions (what and how much) on weighing content from the higher-level system, and to send back the work data on the weighing machine to the higher-level to centrally manage it.

The cause of the anomaly can be traced back

The entire history is recorded with an integrated system, from receiving powder raw materials to weighing and mixing

"PowTrace" can also be introduced by individual process.

"Main raw material weighing tags" and "input weighing tags" are issued in the weighing, filling, and mixing processes. It prevents human error and reliably stores work data. In addition, you can also use it to check "if it is correct with this raw material" before filling it into the blender.

It is a system that accurately grasps the amount of raw material stock in the factory and supports smooth ordering, sales orders, and counting. It also has a function to determine the required amount of raw materials from sales order data and to place orders.

It can also be used as a Manufacturing Execution System (MES).

"PowTrace" can also be used as a "Manufacturing Execution System (MES)" for total management of production content instructions, operator support, and work data management.

If you want to request or download detailed information, or consult with us about technologies or ask questions about our products, contact us from this page.