Products

Weighing Process

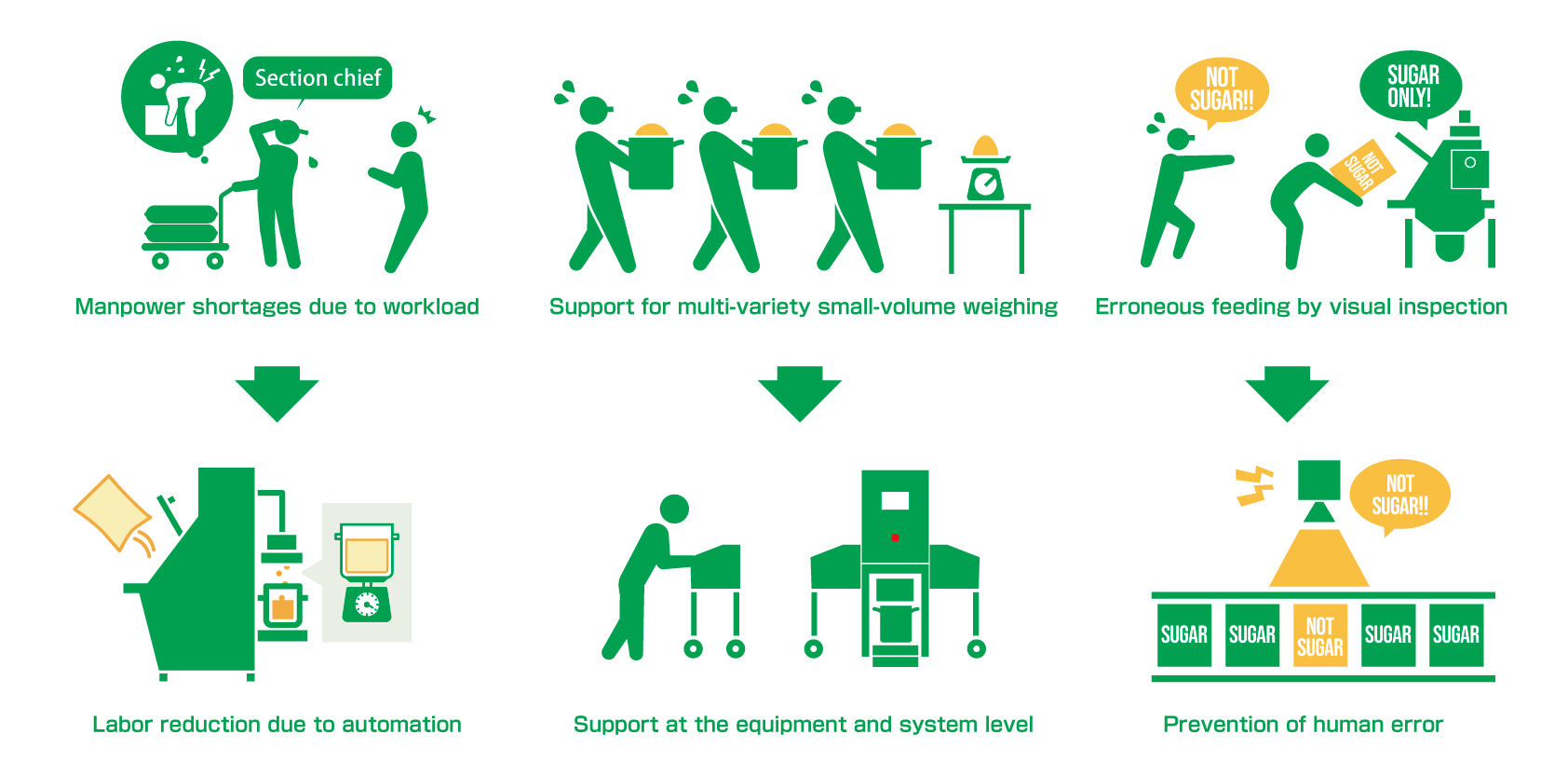

Support for weighing in high-mix, low-volume production.

Also prevent human error when subdividing.

There are various challenges in the weighing process of powder materials, such as manpower shortages onsite and response to multi-variety small-volume weighing. We support solutions by integrating multiple functions, realizing multi-variety weighing with a single unit, and providing a compact design that is easy to install in existing plants.

Application examples of TSUKASA's weighing equipment 1

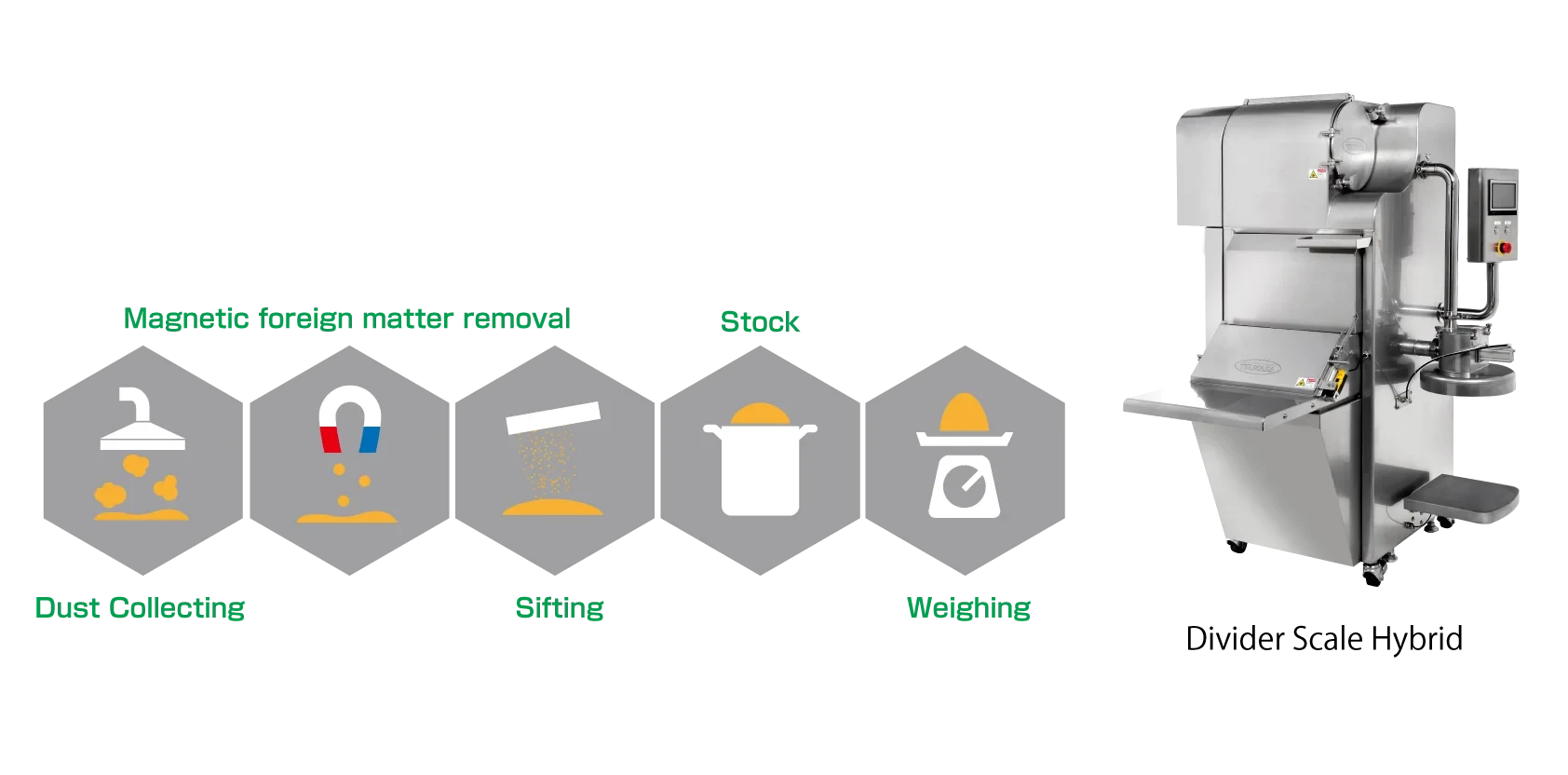

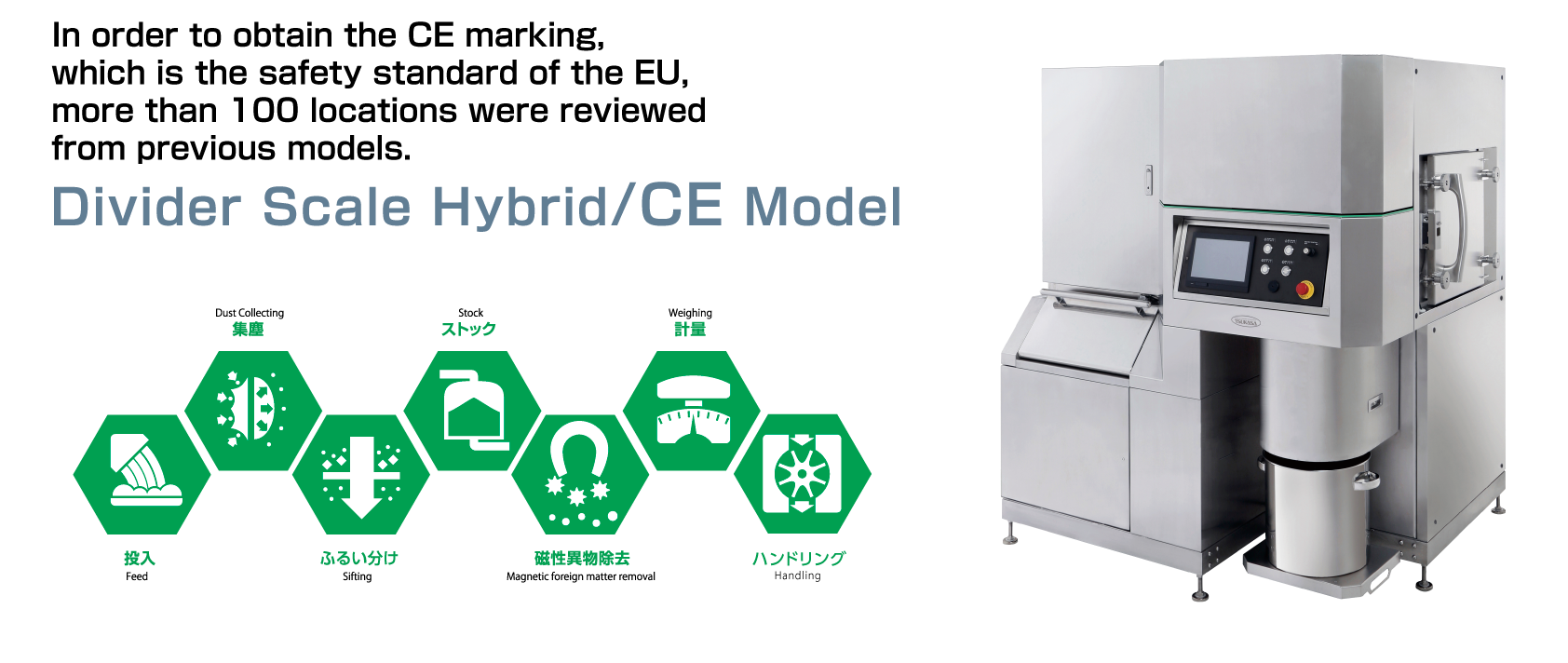

Compact integration of multiple equipment functions

We considered the consolidation of the lines, where different equipment (5 to 6 types) is arranged in a row from powder feeding to weighing. The introduction of the "Divider Scale Hybrid," which integrates dust collection, sieving, stocking, magnetic foreign matter removal, and weighing, has reduced the installation space by one-fifth to one-tenth, making effective use of the entire factory space.

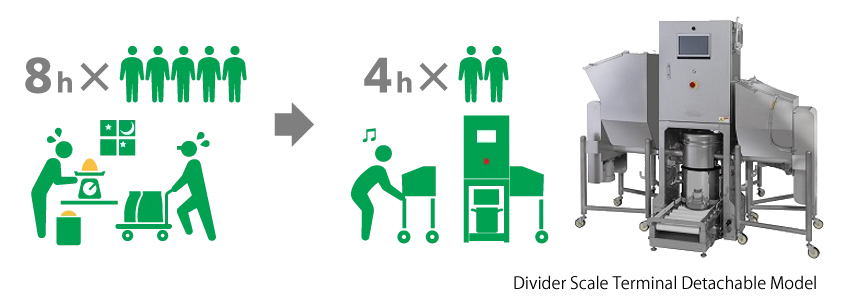

Application examples of TSUKASA's weighing equipment 2

A more efficient weighing of many secondary materials could turn a full day's work of five people to half a day's work by two people.

In the past, a factory used to use more than 10 kinds of secondary materials, and five people would take the entire day to manually weigh them the day before to be used the next day After the introduction of the "Divider Scale Terminal Detachable Model," weighing on the previous day is no longer necessary because weighing for the day can be completed in the morning, even if two people start weighing first thing in the morning on the day of production. Other work can be done in the afternoon, mitigating manpower shortages and tightness in daily work. It also prevents weighing errors.

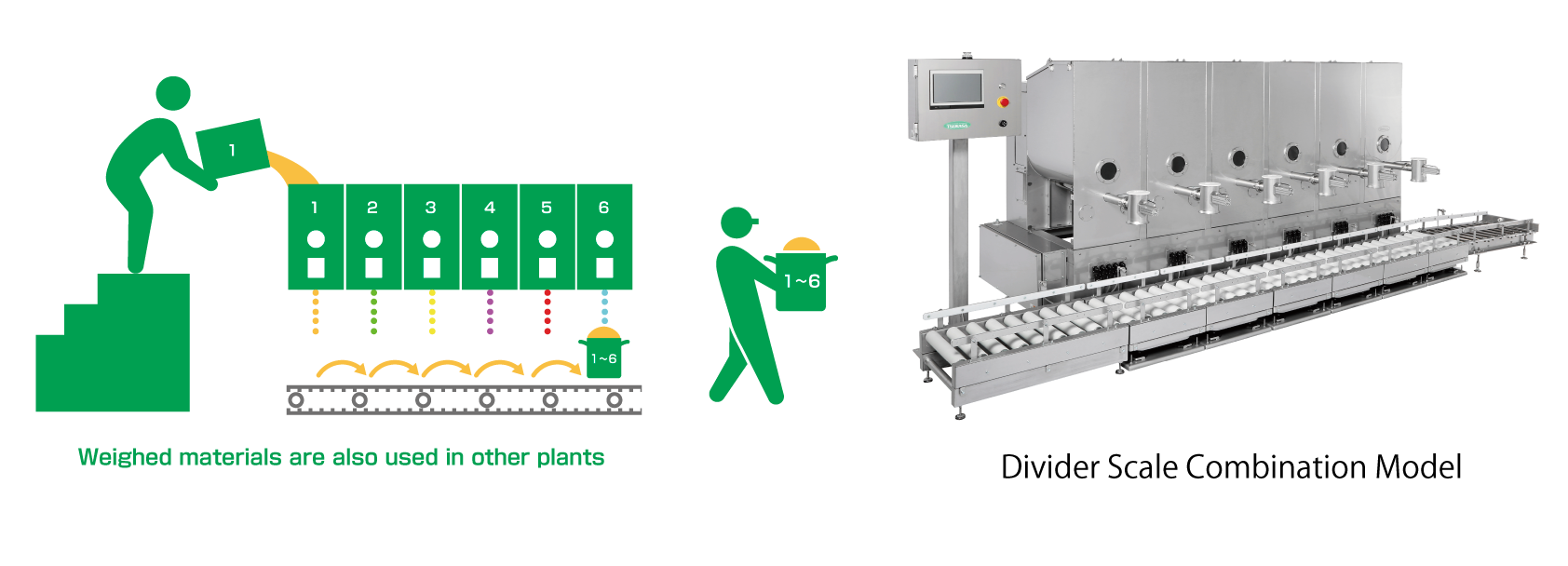

Application examples of TSUKASA's weighing equipment 3

The only human work is attaching and detaching the powder container.

Manually weighed secondary materials are packed and labeled, then sent to several affiliated plants. Because this work requires a great deal of labor and there is a possibility of weighing errors, a combination of "Divider Scale Terminal Detachable Model" and "Combination Model" was introduced to fit the installation space of existing plants. The only human work now is placing the powder container and removing the container after weighing is complete.

TSUKASA lineup expanding even further

Video

Weighing equipment

Divider Scale Terminal Fixed Model(DSC-TDP-5-FX)

Automatic dividing and weighing equipment that can handle multiple raw materials using a stocker-fixed modelMORE >

Divider Scale Terminal Detachable Model(DSC-TDP-4-DE)

Automatic dividing and weighing equipment that can handle multiple raw materials using a stocker detachable modelMORE >

Divider Scale Simple(DSC-S)

Automatic dividing/weighing equipment appropriate for measuring and dividing supplemental materials and additivesMORE >

Divider Scale Combination Model(DSC-C)

Automatic dividing/weighing equipment which can automatically weigh a wide variety of materialsMORE >

Divider Scale Hybrid 200L(DSC-HV-200)

Weighing equipment that promotes compactness and achieves more effective use of plant spaceMORE >

Divider Scale Hybrid 50L(DSC-HV-50)

A weighing machine with a hybrid function in pursuit of miniaturizationMORE >

Divider Scale Receiver Model(DSC-RC)

Weighing equipment which stocks and automatically supplies materials conveyed with airMORE >

Divider Scale Equipment-mounted Model(DSC-EM)

Weighing equipment attachable to the discharge port of a silo or mixerMORE >

PowScale Hopper Model(PS-HP)

Hopper model weighing equipment with a simple and efficient designMORE >

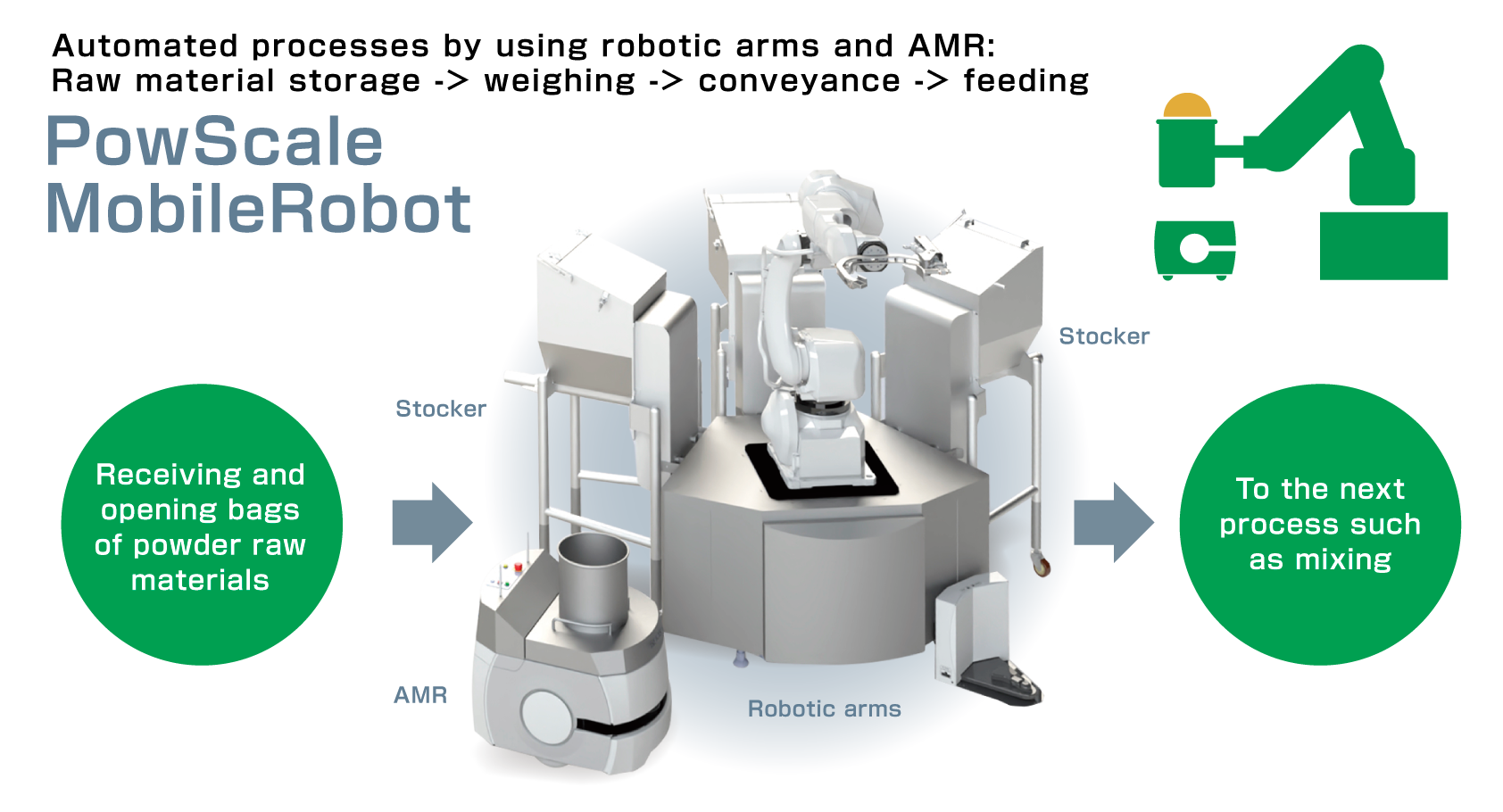

Divider Scale Mobile Robot

Automated processes by using robotic arms and AMR: Raw material storage -> weighing -> conveyance -> feedingMORE >

Divider Scale Hybrid/CE Model

Automatic weighing equipment with EU safety standard, i.e., CE markingMORE >

If you want to request or download detailed information, or consult with us about technologies or ask questions about our products, contact us from this page.