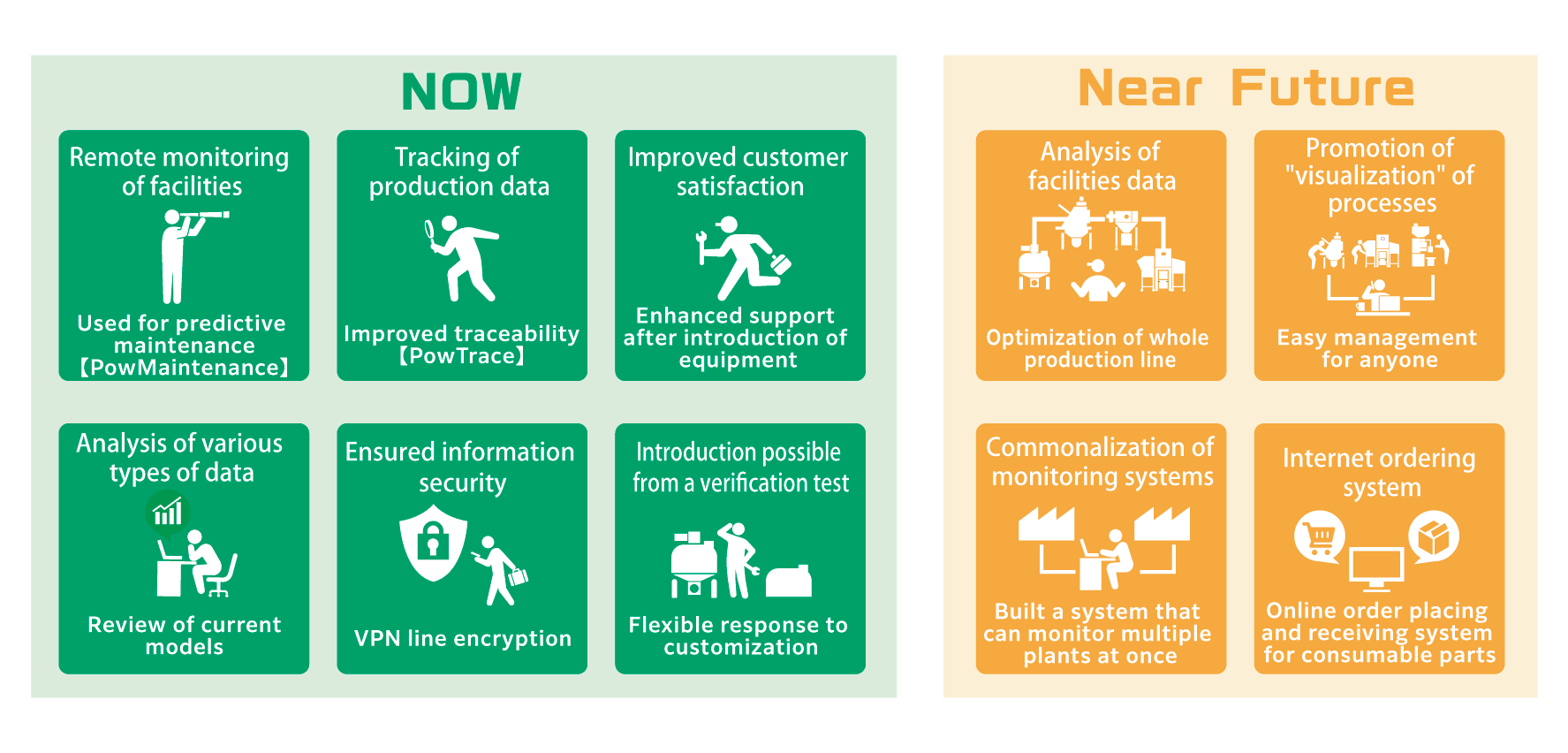

TSUKASA DX【Present to future】

With the aim of optimizing the entire line, we are exploring new systems from multiple perspectives.

From systems that have already been achieved to new systems aimed at the ideal future. We will promote DX from a variety of perspectives.

Digital Transformation

As a comprehensive manufacturer of powder equipment, we shift from automation of individual facilities to optimization of the "entire production line"

Remotely monitoring equipment in the plant to ensure smooth operation. We support predictive maintenance and quick troubleshooting.

Centralized management of work data for each production process. In the event of a problem, you can trace back to where the problem occurred.

We value our customers' satisfaction.

Based on the work data of each equipment and individual facilities, the department will advise you on what to do with the next facility renewal.

We take all possible security measures for information transmission, such as the use of a VPN line that requires an encryption key and the permission of the connection on the customer side.

We respond to customer requests such as "Can we add such functions to the system?" with our comprehensive capabilities of "manufacturing, technology, and sales."

We analyze the data obtained by "PowMaintenance" and "PowTrace" to propose the future direction of your entire production line.

We promote "visualization" of "when, who processed what and how much", and "what was the result", and thoroughly eliminate human errors.

We will build an information sharing system between multiple customer factories, aiming to centrally manage operation status and production data, and make maximum use of it.

In cases where frequent replacement of the same part is required, orders can be placed via the Internet to shorten the lead time.