Handling Process

Constant conveyance and constant supply, realizing stable discharge

Constant conveyance and constant supply, realizing stable discharge

Conveyance equipment

Pulse Feeder Mini(MP)

Small and space-saving conveyance equipment

Features

⚫︎Small type high-density batch conveyor

⚫︎Appropriate for pressurized low speed transport (6-10 m/sec) of granular materials of food, chemical and pharmaceutical products.

⚫︎Please choose discharge with an air ration type and the PowRotor type.

⚫︎Resolution washing is possible

⚫︎Appropriate for pressurized low speed transport (6-10 m/sec) of granular materials of food, chemical and pharmaceutical products.

⚫︎Please choose discharge with an air ration type and the PowRotor type.

⚫︎Resolution washing is possible

Applications

Wheat flour, powdered starch, granulated sugar, dextrose, coffee, mixed powder and granules, such as soup, pharmaceutical powders, ceramic powders, cement, slaked lime, powdered carbon, rice, plastic pellets, etc.

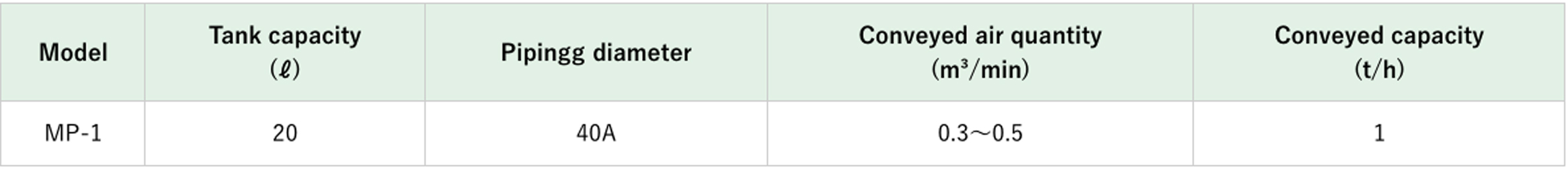

*Specifications may vary from standard product according to such factors as type of particulate and conveyance conditions.

*The conveyed air quantity converted atmospheric pressure.

*The capacities shown above are when using wheat flour(apparent specific gravity: γ=0.5、total conveyance distance:20m).

*The conveyed air quantity converted atmospheric pressure.

*The capacities shown above are when using wheat flour(apparent specific gravity: γ=0.5、total conveyance distance:20m).