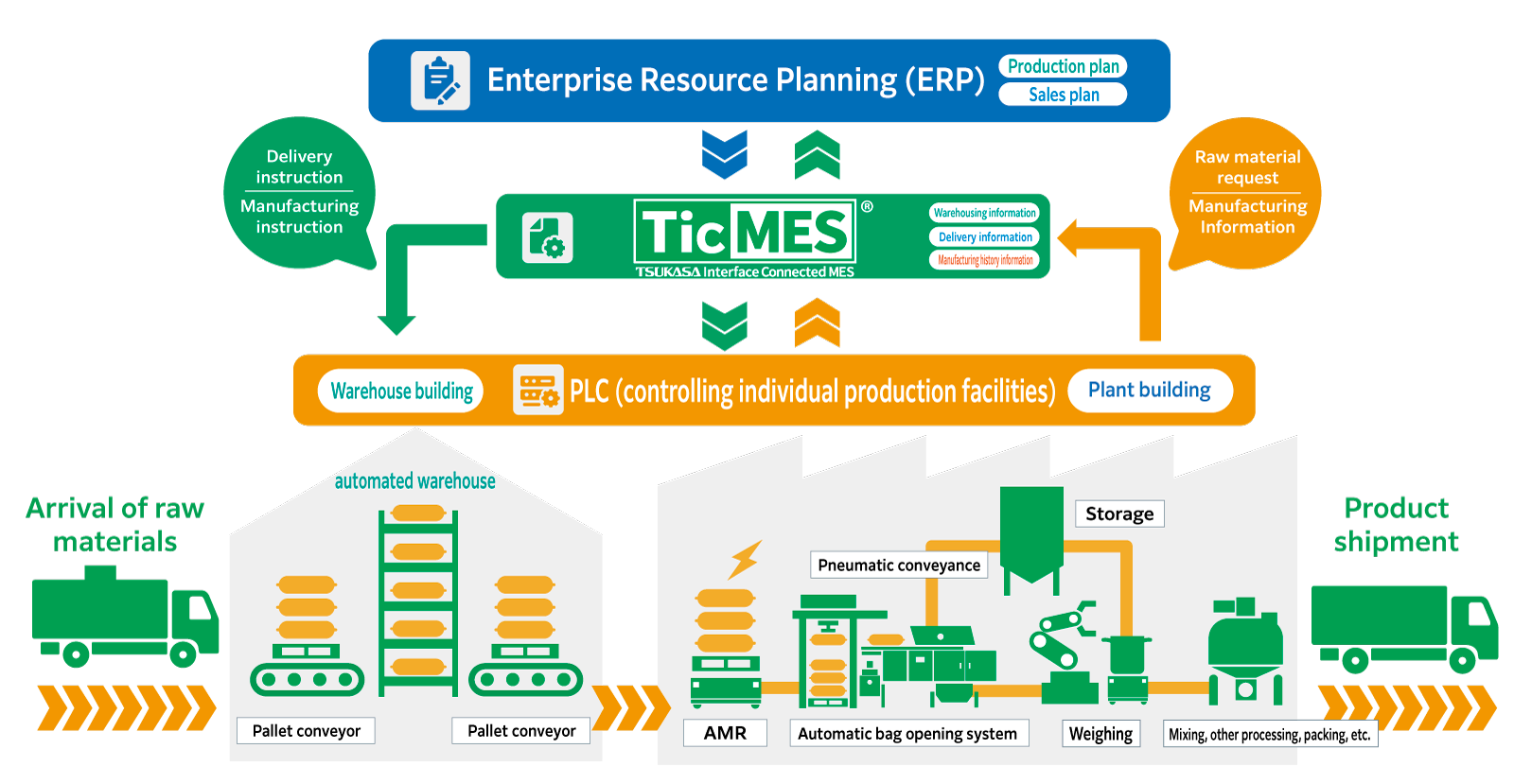

As a system integrator

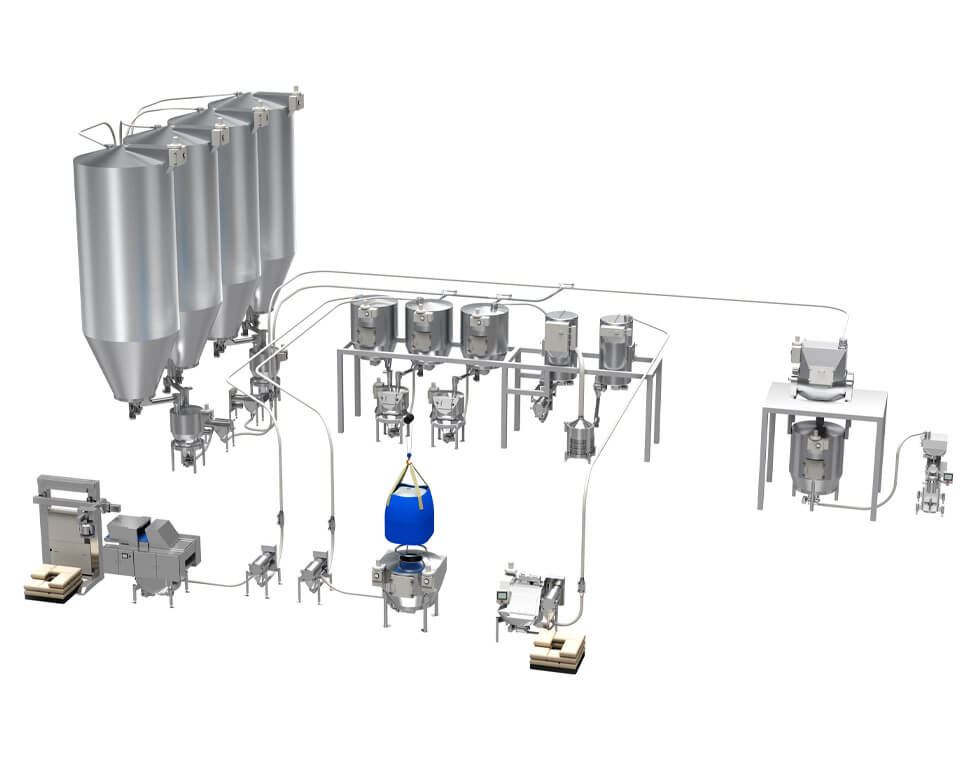

We offer integrated proposals for development and operation of production lines as SIer.

This includes linking the entire production system with a "smart factory" and an "automated warehouse system" that connects the entire production system with a network. In TSUKASA, SIer, a system integrator, already has a track record of actual introductions and operations, and will continue to contribute to the rationalization and efficiency of customers' production sites from all angles.

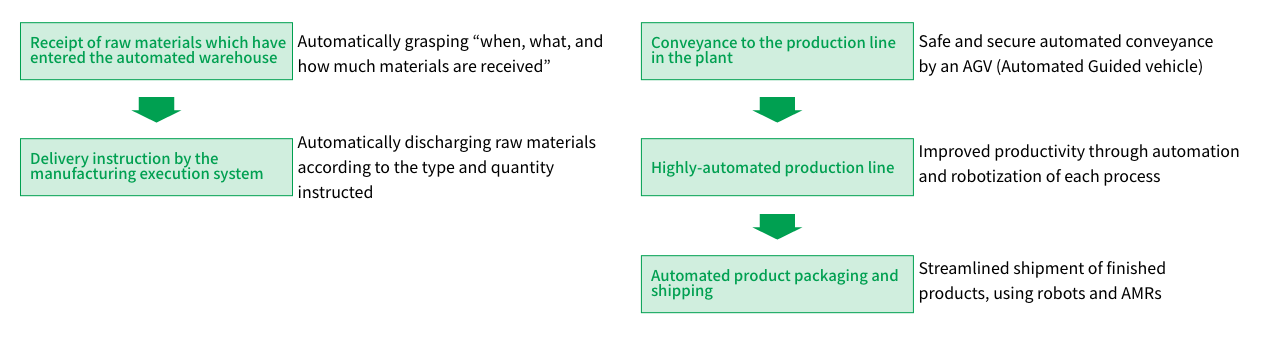

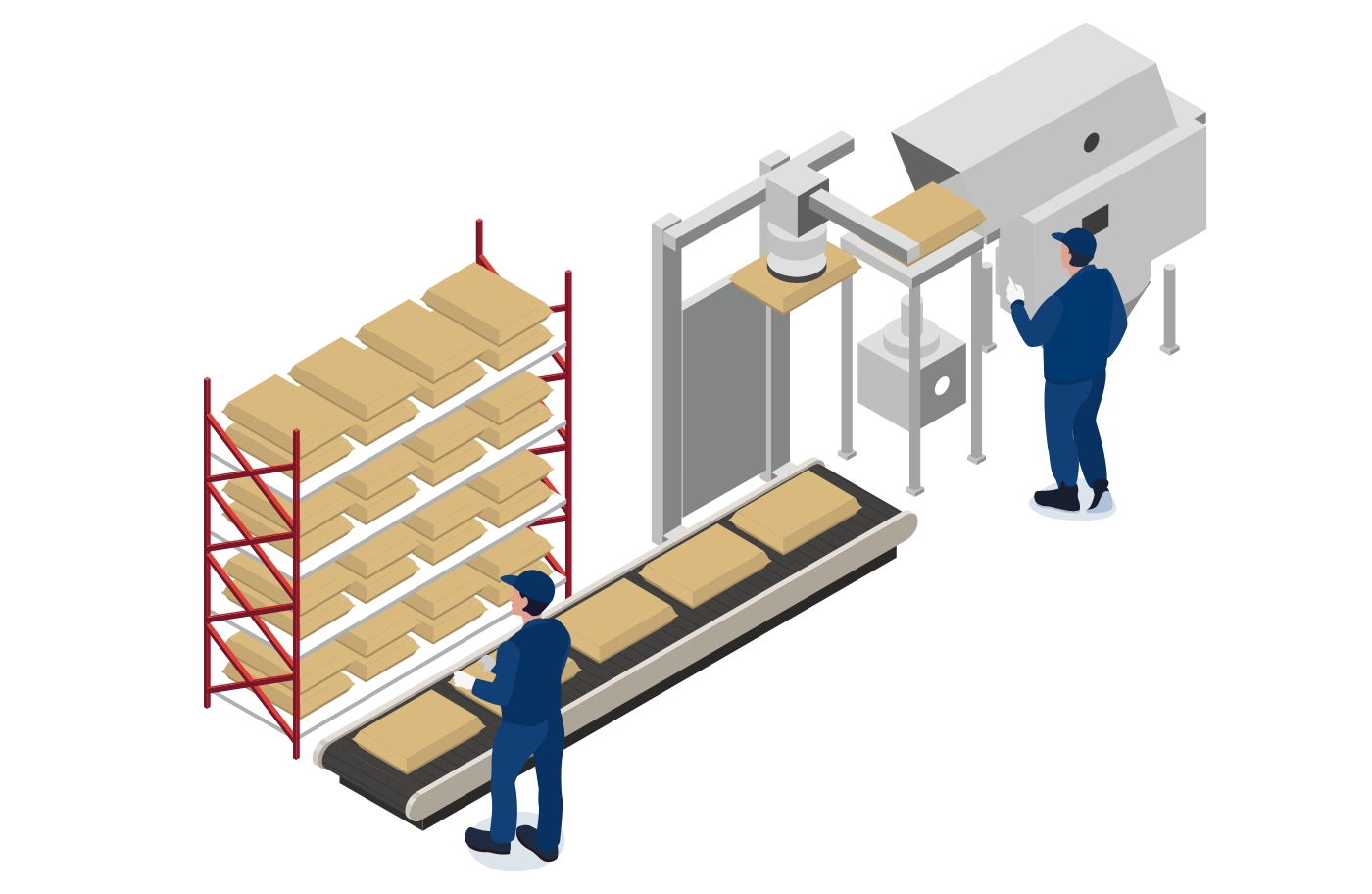

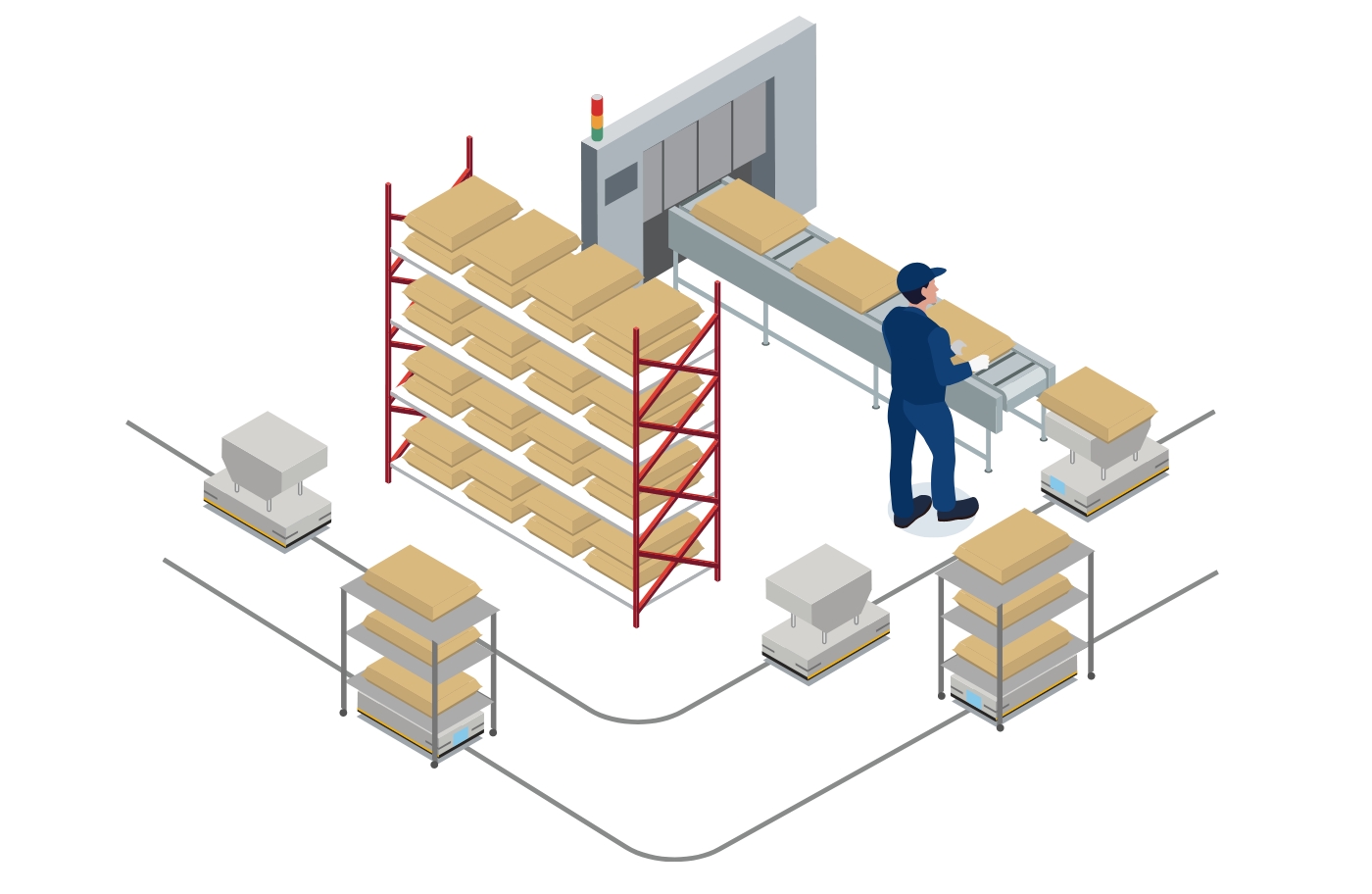

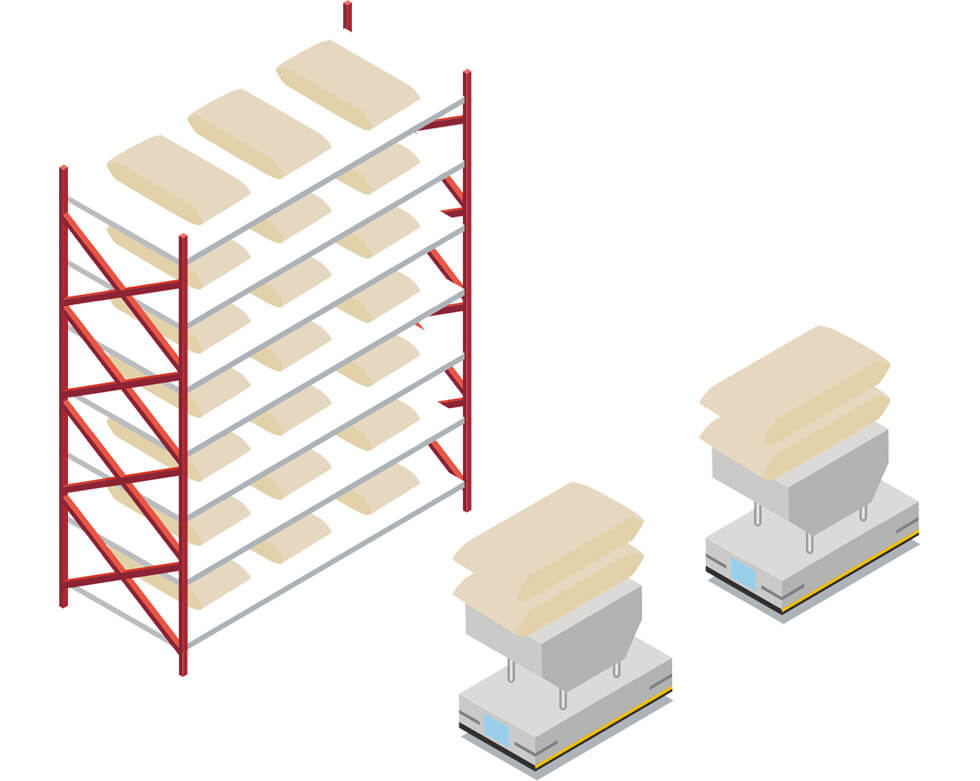

Automated warehouse system

Based on instructions from the higher-level system, this system enables automation of the process from receiving raw materials in warehouses to supplying them to production lines. Inventory data can also be managed centrally.

AMR

An AMR (autonomous mobile robot) is used to convey raw materials in a plant. It is highly safe because there is no need for workers to convey raw materials, and it also creates room for plant space.

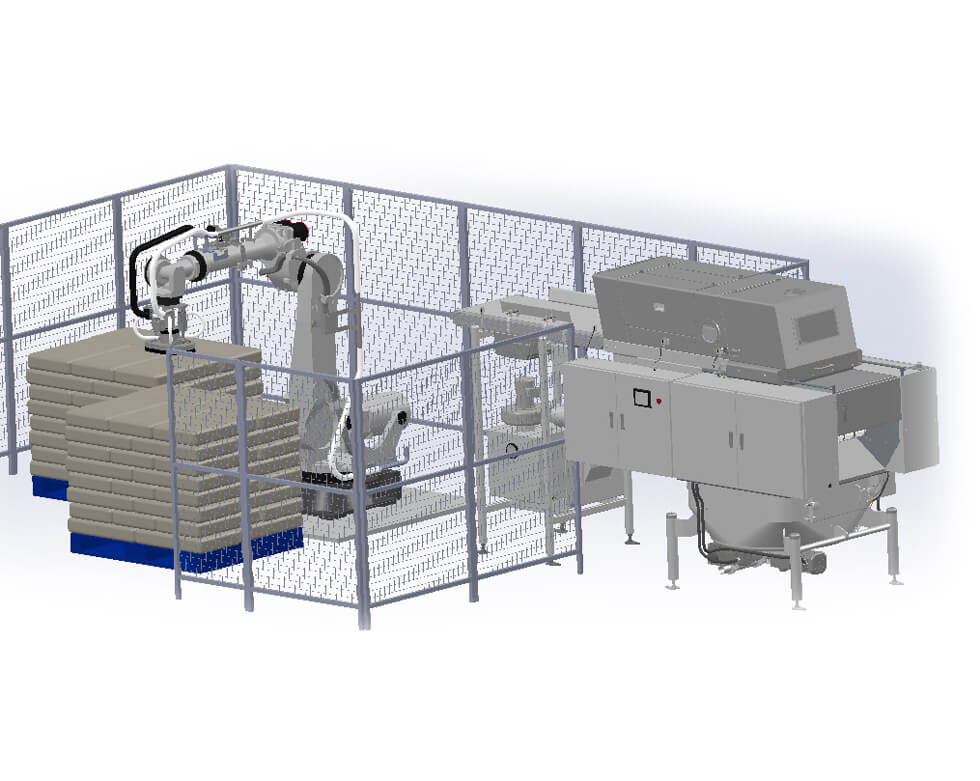

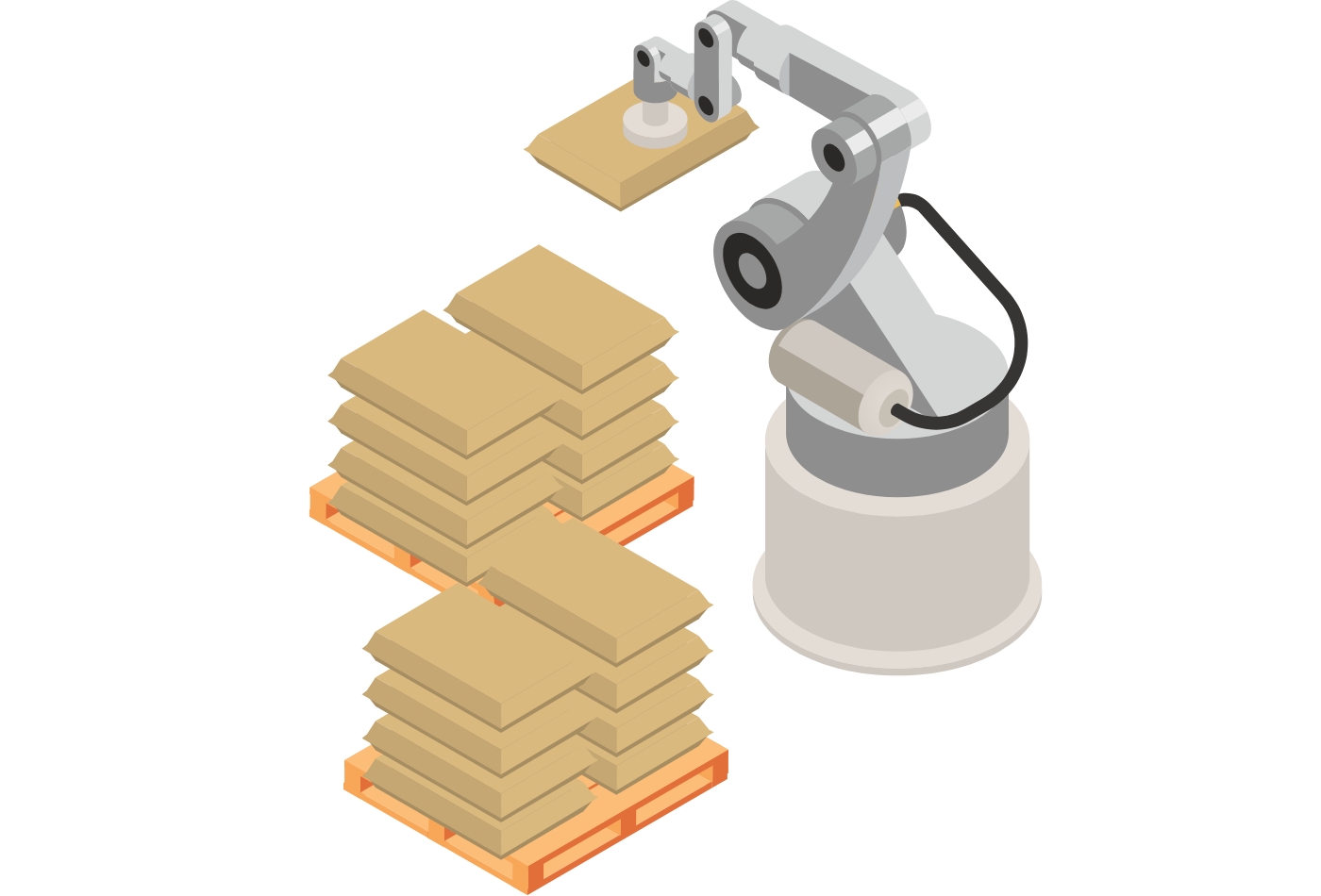

Articulated robot

The articulated robotic arm enables the supply of raw materials from multiple pallets and multiple weighing.

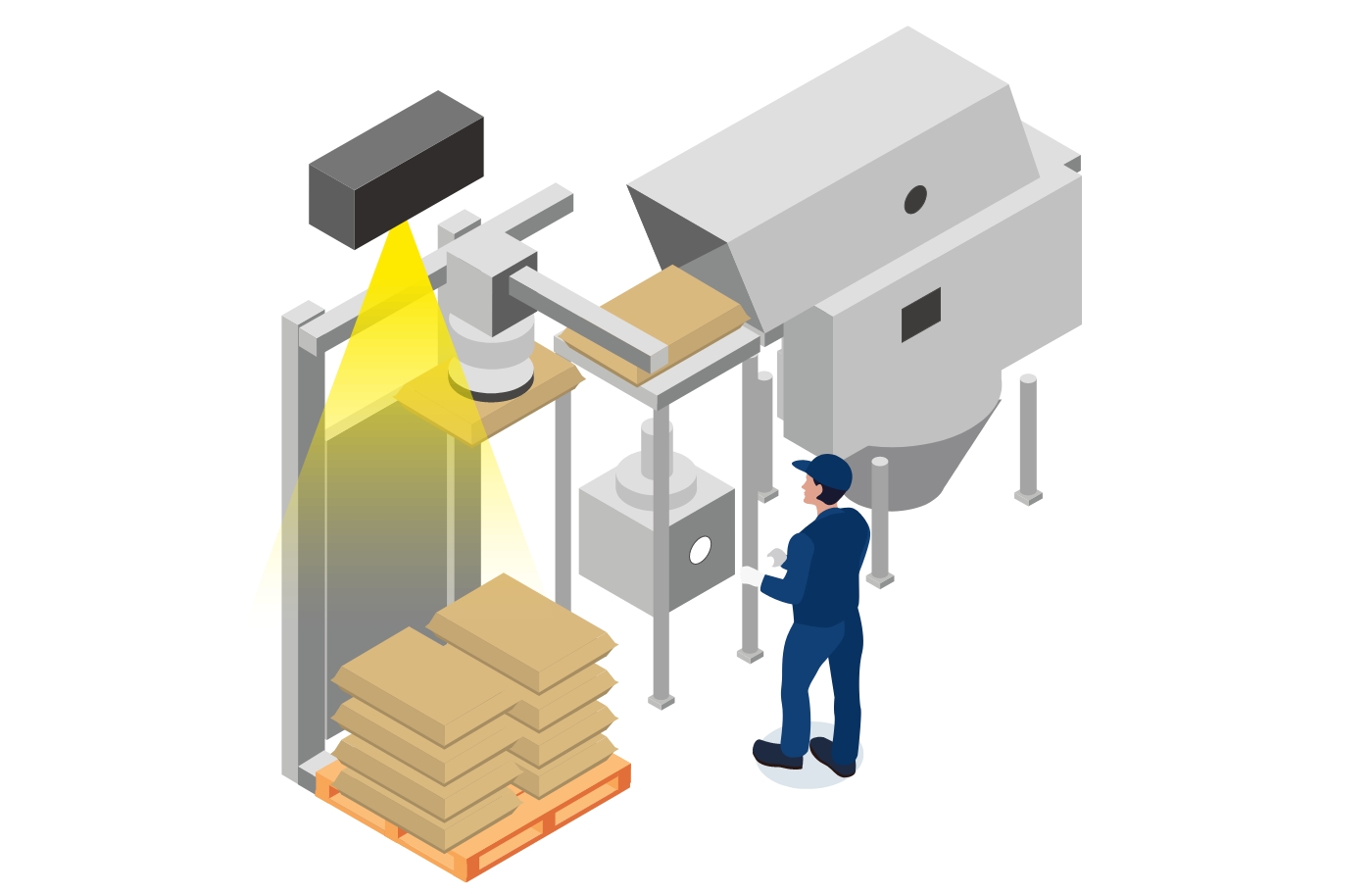

PV(PowVision)

The 3D vision camera automatically recognizes the position, height, and orientation of the raw material bag. Erroneous feeding of raw materials can be prevented.

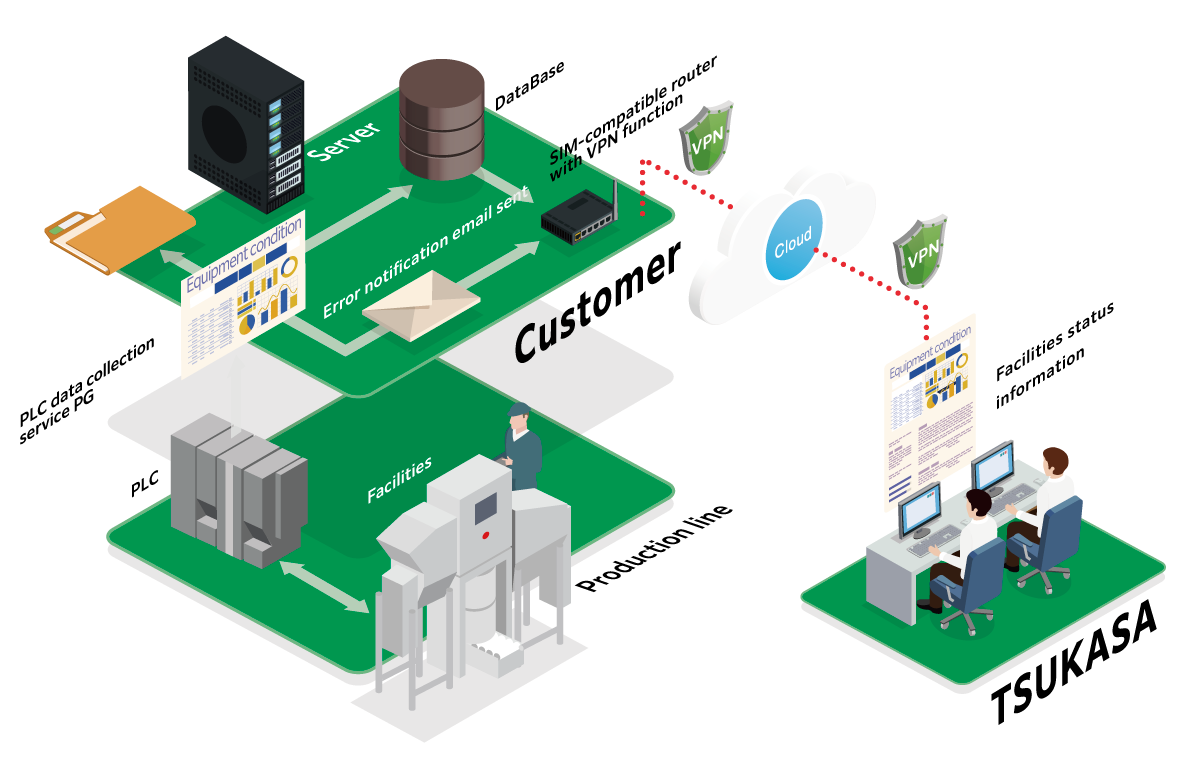

PowMaintenance

Remote monitoring by installing sensors on each device. It achieves appropriate "predictive maintenance."

PowTrace

It centrally manages the work history of each process. You can reliably track down the cause of the trouble.

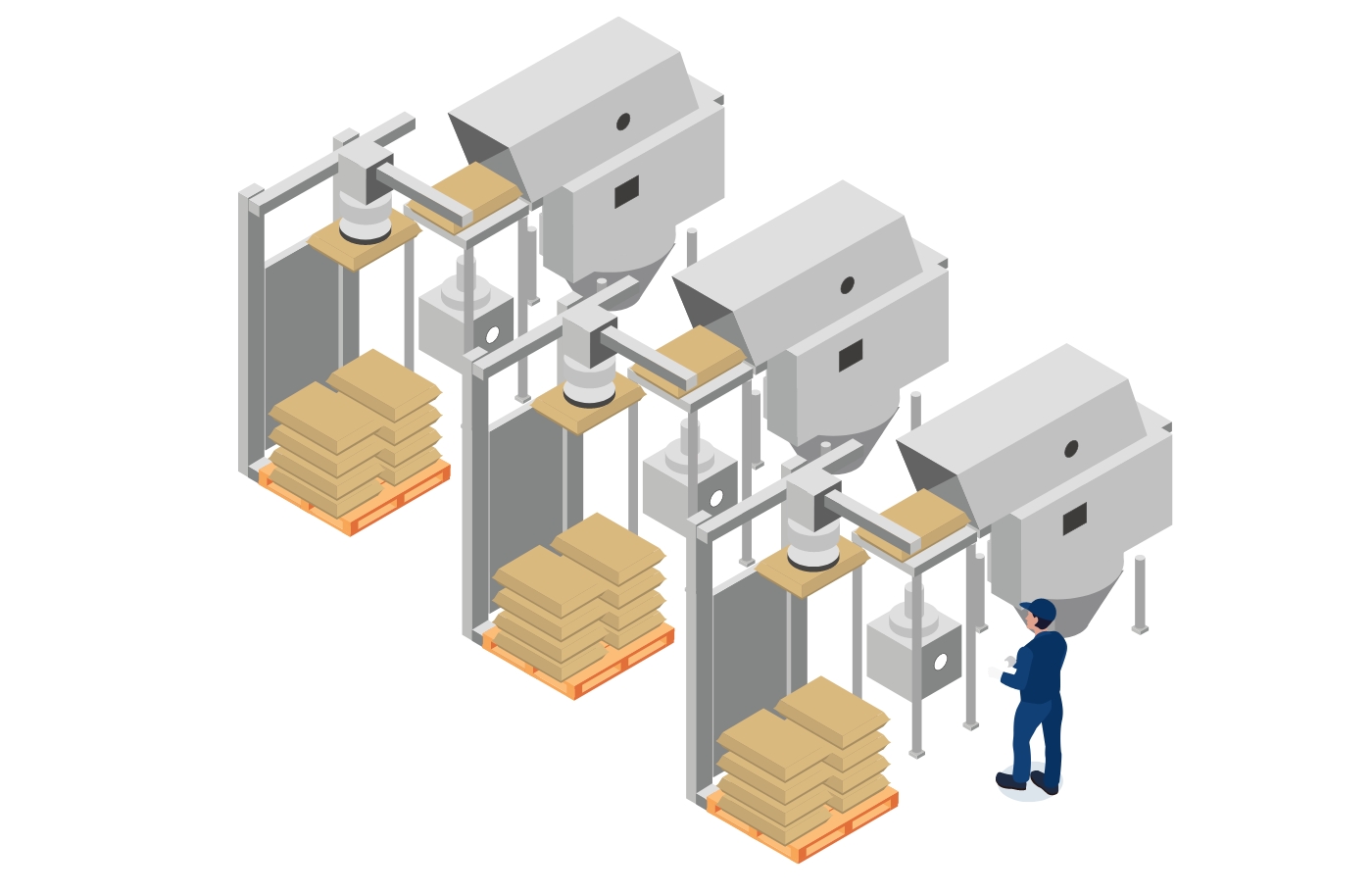

Multi-line operation

It is also possible to operate multiple automatic bag opening systems in parallel. It contributes to the efficiency of production sites that handle large quantities and several types of raw materials.

Advantages of TSUKASA SIer

Multiple achievements as a SIer, such as linking with an automated warehouse

A comprehensive manufacturer of powder equipment that is familiar with the customer's production lines

Best matching of TSUKASA powder equipment + a system