Products

Difficult-to-process materials

Titanium, Inconel, Hastelloy, and Stainless Steel.

Enter new fields with expert skills and cutting-edge equipment.

We are developing products with difficult-to-process materials that are used in the food, chemical, pharmaceutical and electronic fields.

TSUKASA's powder processing equipment is utilized in various production sites such as food, pharmaceuticals, aerospace, chemicals, electronics, and more, where 'higher added value than ever before' may be required depending on the characteristics of the powder and the working environment. Therefore, in response to the request for 'powder processing equipment beyond conventional standards,' we actively pursue product development using difficult-to-process materials to assist in creating new value in product and component manufacturing.

If you are looking for higher specifications of powder equipment, consider using difficult-to-process materials!

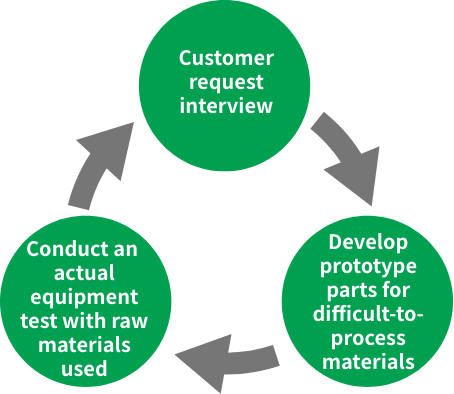

Creating further value together with our customers.

Production of products using difficult-to-process materials begins based on customer needs, such as "I want to increase the strength of this part even more." At TSUKASA, we care about "sharing values with our customers" and work together to utilize difficult-to-process materials.

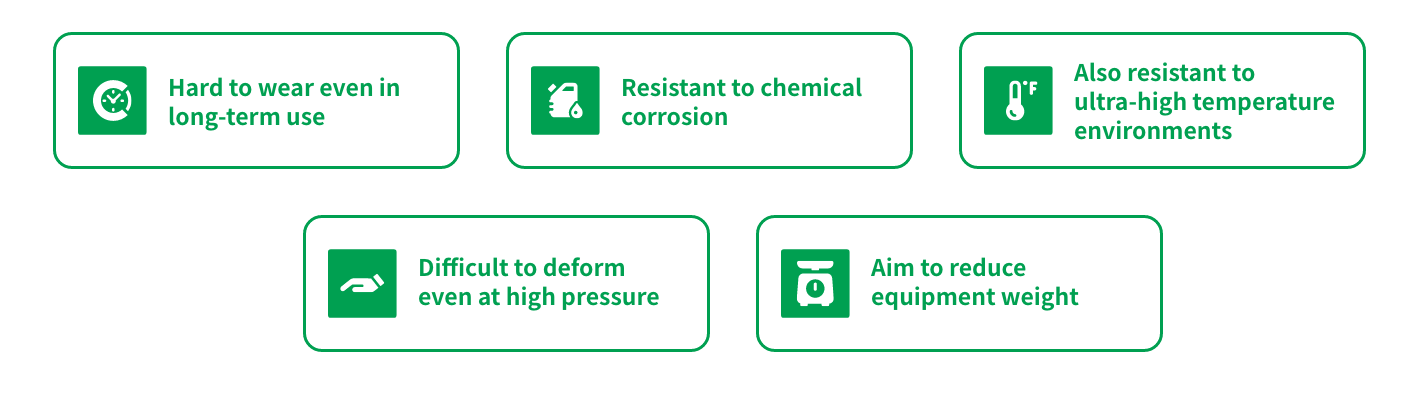

High strength, high temperature characteristics, oxidation resistance, corrosion resistance, and weight reduction

TSUKASA products using difficult-to-process materials (only a part of examples)

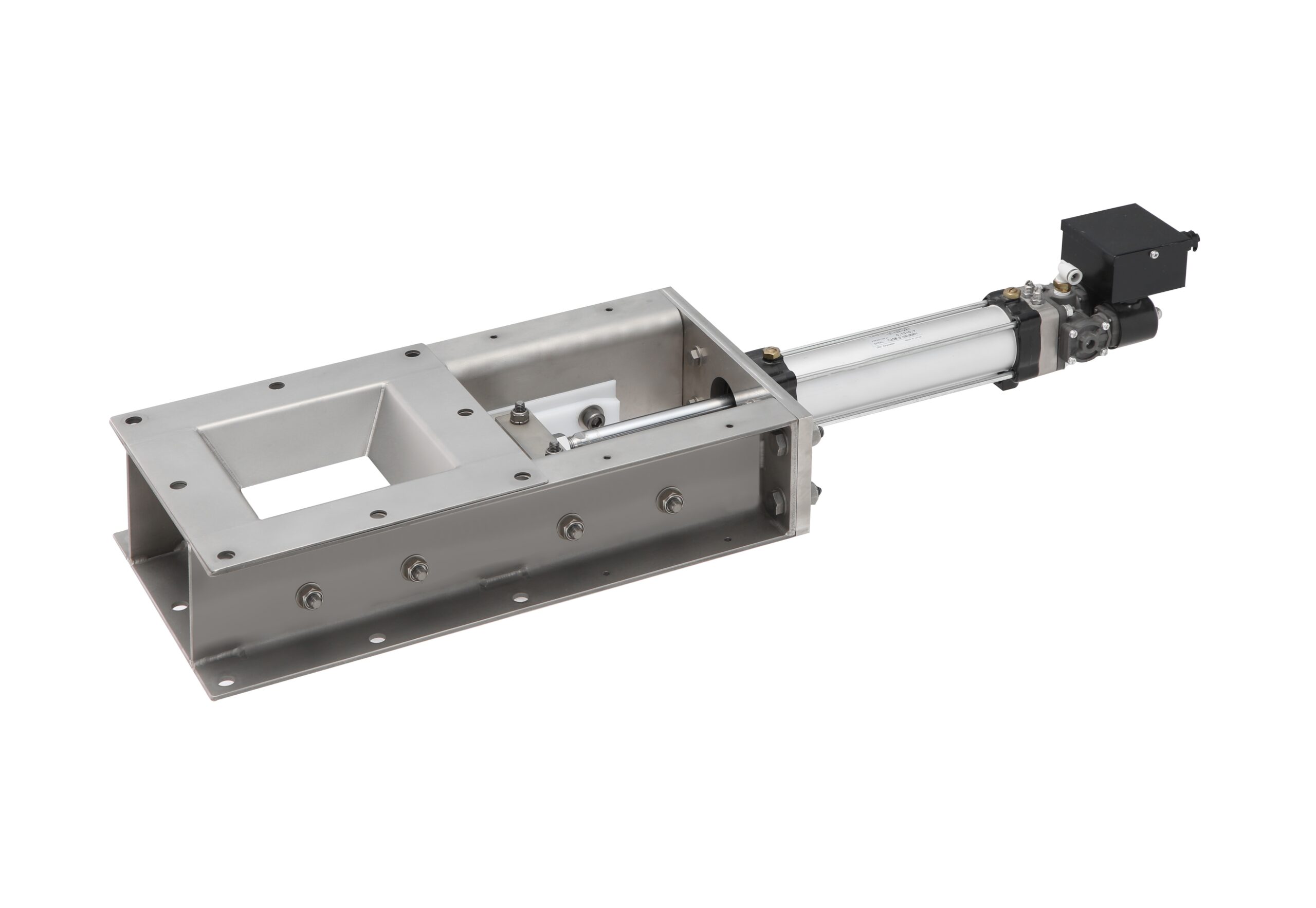

Titanium

Titanium has become a familiar material such as used in golf clubs. It is a relatively new material that has been in practical use for 70 years. It is lightweight, strong, and corrosion-resistant, and is used in a wide range of applications, from materials for space and aircraft to various plant facilities, construction materials, and daily necessities. It is also a difficult material for welding, stamping, and cutting, and its processing requires advanced techniques and methods that match the characteristics of titanium.

PowGate Slide with Titanium

Inconel

Inconel has excellent high-temperature properties such as heat resistance, corrosion resistance, oxidation resistance, and creep resistance, making it ideal for the aerospace and aerospace industries. It is used in various fields such as the nuclear power industry and high-end mufflers for automobiles. However, it is one of the alloys that are difficult to process in machining such as cutting.

Scraper forTable Feeder with Inconel

Hastelloy

Hastelloy is an alloy with high corrosion and heat resistance and is suitable for use in corrosive and high temperature environments. It is mainly used for components that require corrosion resistance and heat resistance, such as combustion chambers of jet engines. It is a difficult material to process, as it has high hardness and high toughness, but it has very poor machinability because it hardens further in the processing.

-e1720056501996.jpg)

Screw Feeder with Hastelloy

PowRotor Light-weight Sanitary Specifications with Hastelloy

Stainless steel

Stainless steel means "steel that does not rust". Stainless steel is used in a variety of everyday applications such as tableware and home appliances, as well as mobile phones, computers, and automobiles. In addition to corrosion resistance, it has low thermal conductivity and excellent heat resistance and thermal insulation, but it is a material that is unexpectedly difficult to process such as work hardening in spite of its high popularization.

PowChange

(all made of stainless steel; for rechargeable battery type)

(all made of stainless steel; for rechargeable battery type)

If you want to request or download detailed information, or consult with us about technologies or ask questions about our products, contact us from this page.