Products

PowMaintenance

Remote monitoring of equipment operation status.

Plan appropriate maintenance by "Predictive Maintenance".

Sensors are installed on each piece of equipment to monitor the operation status

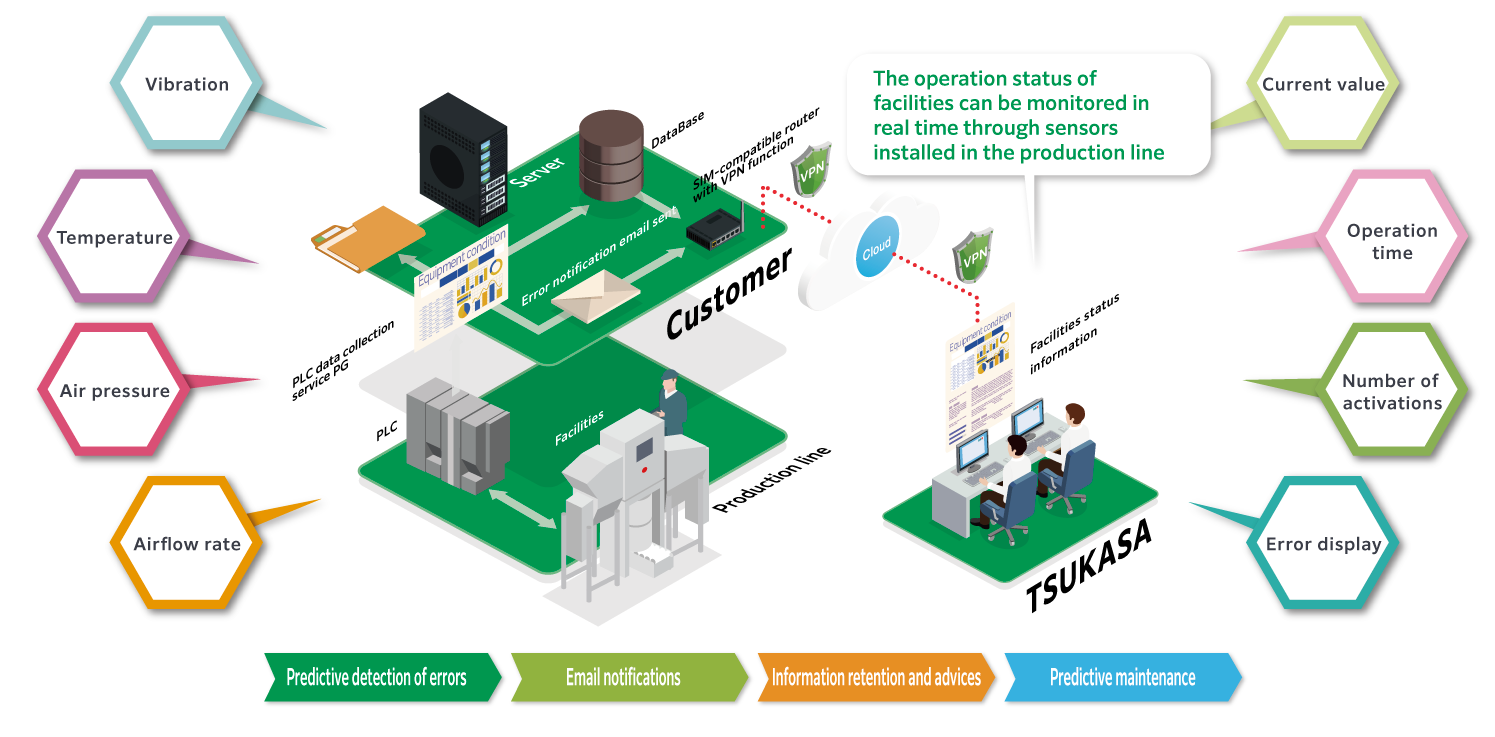

"PowMaintenance" is a system that realizes "remote monitoring" of your factory. Sensors are installed on equipment in the factory to measure data such as vibration, temperature, and pressure. The data is sent to the TSUKASA monitoring program via a highly secure VPN line, and the operation status is monitored in real time.

If there are signs of trouble, the customer’s facility manager or TSUKASA representative will be automatically notified by email. TSUKASA"CS (Customer Support) Center" will provide on-site support in the event that an emergency response is required.

※The VPN line cannot be accessed without an encryption key. In addition, it is impossible for a third party to grasp the contents of the equipment as the operating status of the equipment to be transmitted as a list of numerical data.

If there are signs of trouble, the customer’s facility manager or TSUKASA representative will be automatically notified by email. TSUKASA"CS (Customer Support) Center" will provide on-site support in the event that an emergency response is required.

※The VPN line cannot be accessed without an encryption key. In addition, it is impossible for a third party to grasp the contents of the equipment as the operating status of the equipment to be transmitted as a list of numerical data.

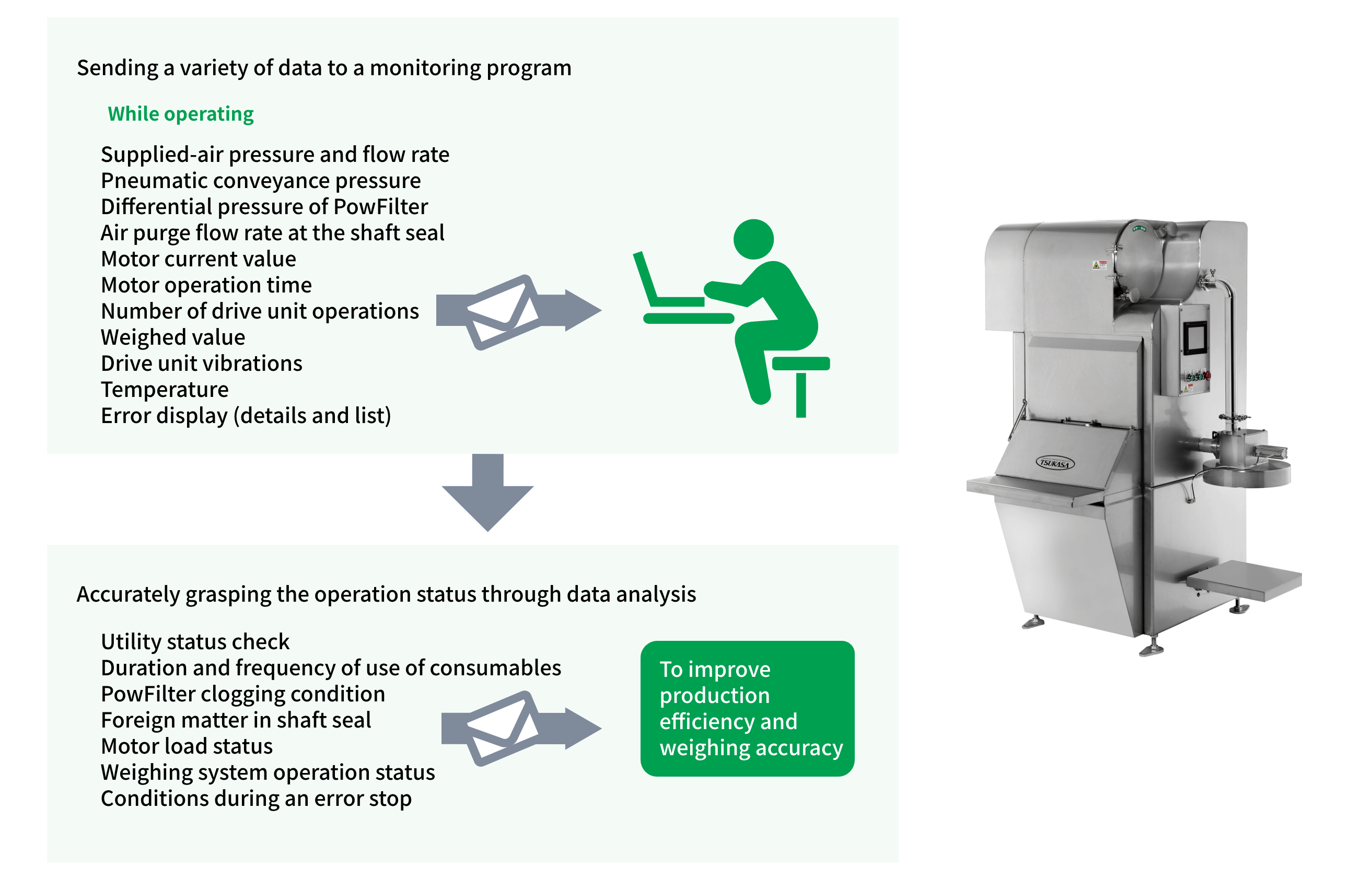

Example of introduction in "Divider Scale Hybrid Model" (weighing equipment)

The customer only needs to configure the touch screen

With the use of "PowMaintenance", the customer is only required to set up the touch screen on the control panel. It is possible to change settings, check history, and monitor with simple operation. You and TSUKASA can look at the same monitor screen and give advice such as "check here", or change the remote configuration from TSUKASA (only if the customer allows).

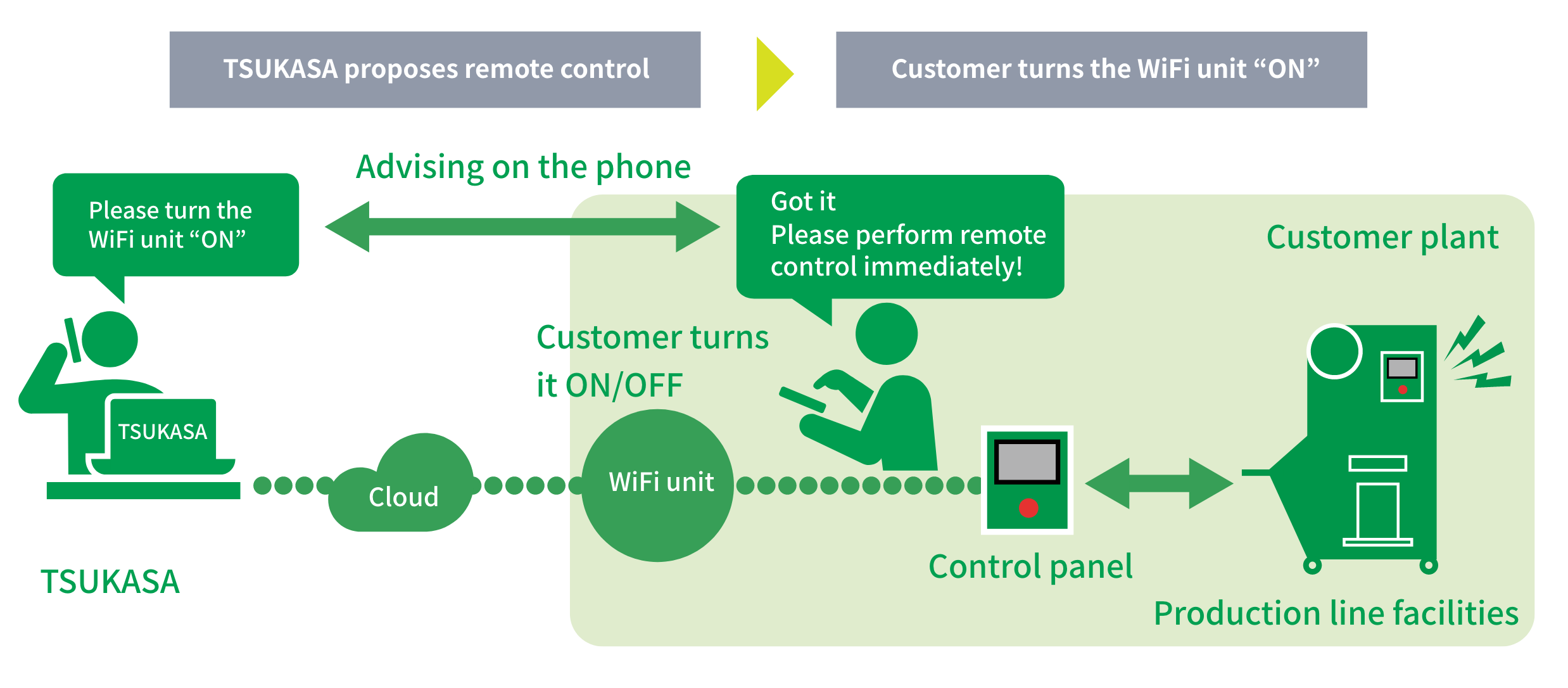

"PowMaintenance" can be installed from one device!

Integrate the Wi-Fi unit in the control cabinet of one of your devices. When the switch is turned "on" at the customer's discretion, such as during telephone consultation in an emergency situation, the control panel can be remotely operated from TSUKASA to change settings and adjust settings. The use of a VPN connection also provides peace of mind in terms of security.

If you want to request or download detailed information, or consult with us about technologies or ask questions about our products, contact us from this page.