Products

Sifting and Foreign-material Removal Process

Reliable sieving of powder raw materials

and removal of non-magnetic and magnetic foreign matters.

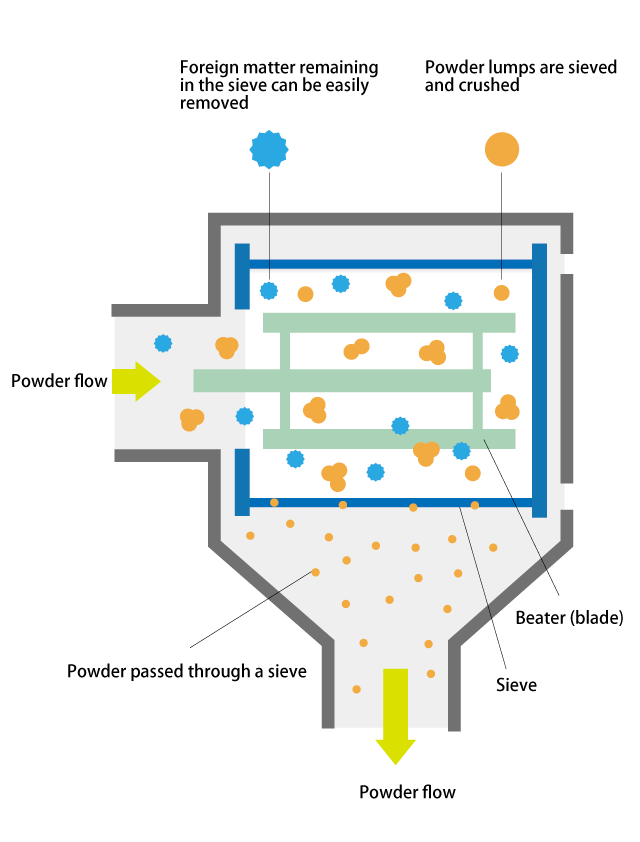

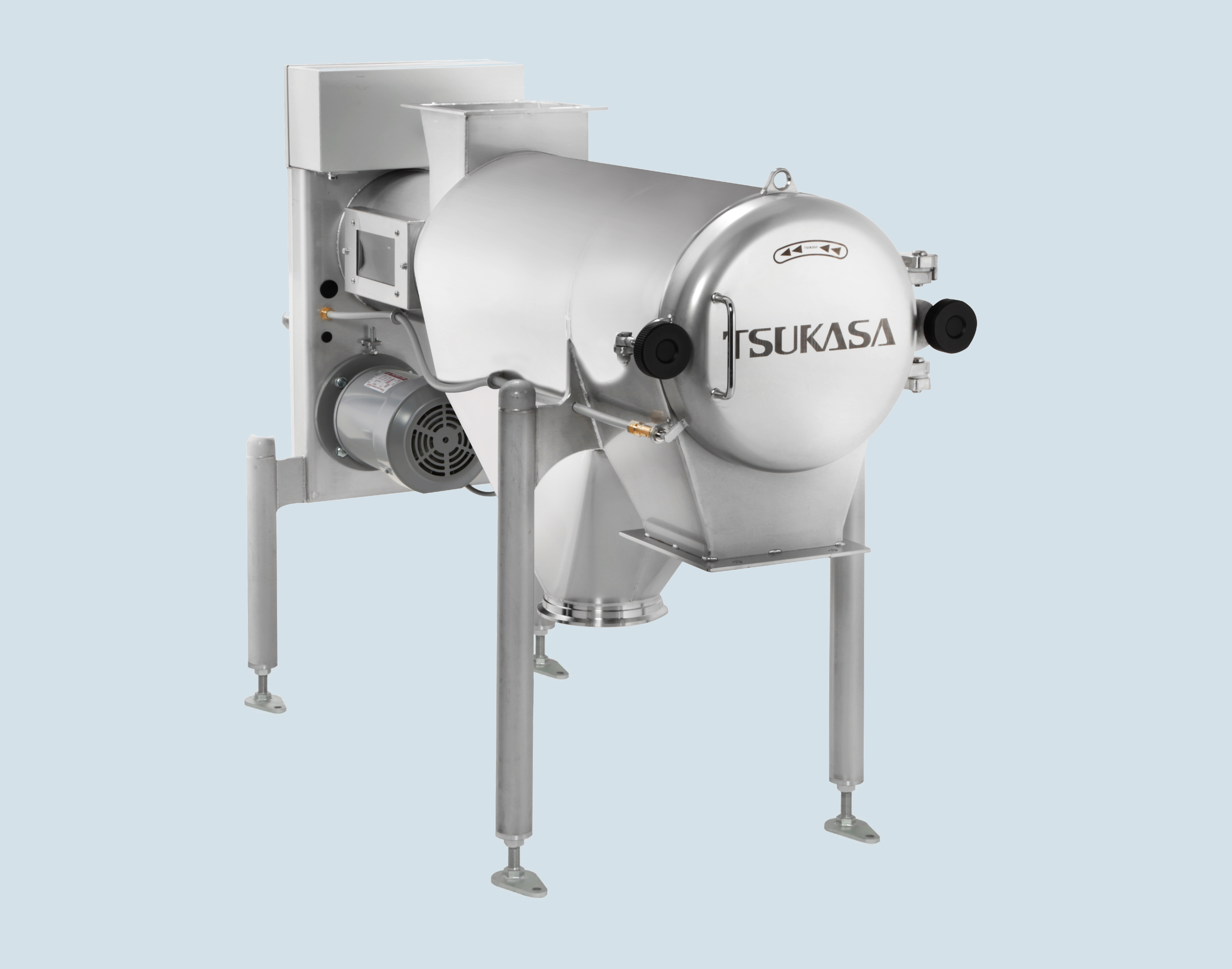

TSUKASA's LINESIFTER® uses a cylindrical structure.A high-speed rotating beater (blade) is used to break up powder lumps while sifting.During this process, the powder contains a lot of air, which makes it easier for the materials to disperse in the next process (mixing, kneading, etc.). In addition, foreign matter remaining in the sieve (net) can be easily inspected and removed.

LINESIFTER® construction

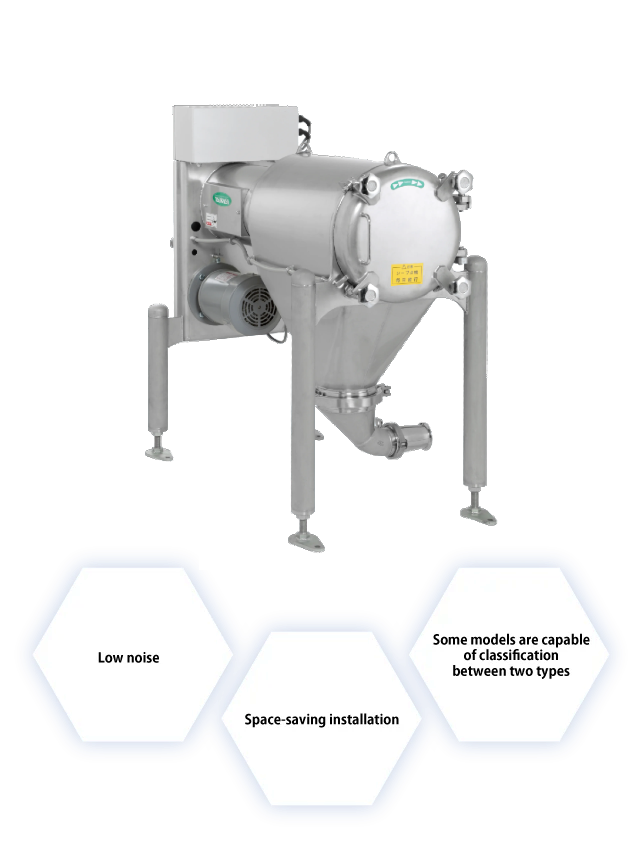

LINESIFTER®︎ Standard Model(LS)

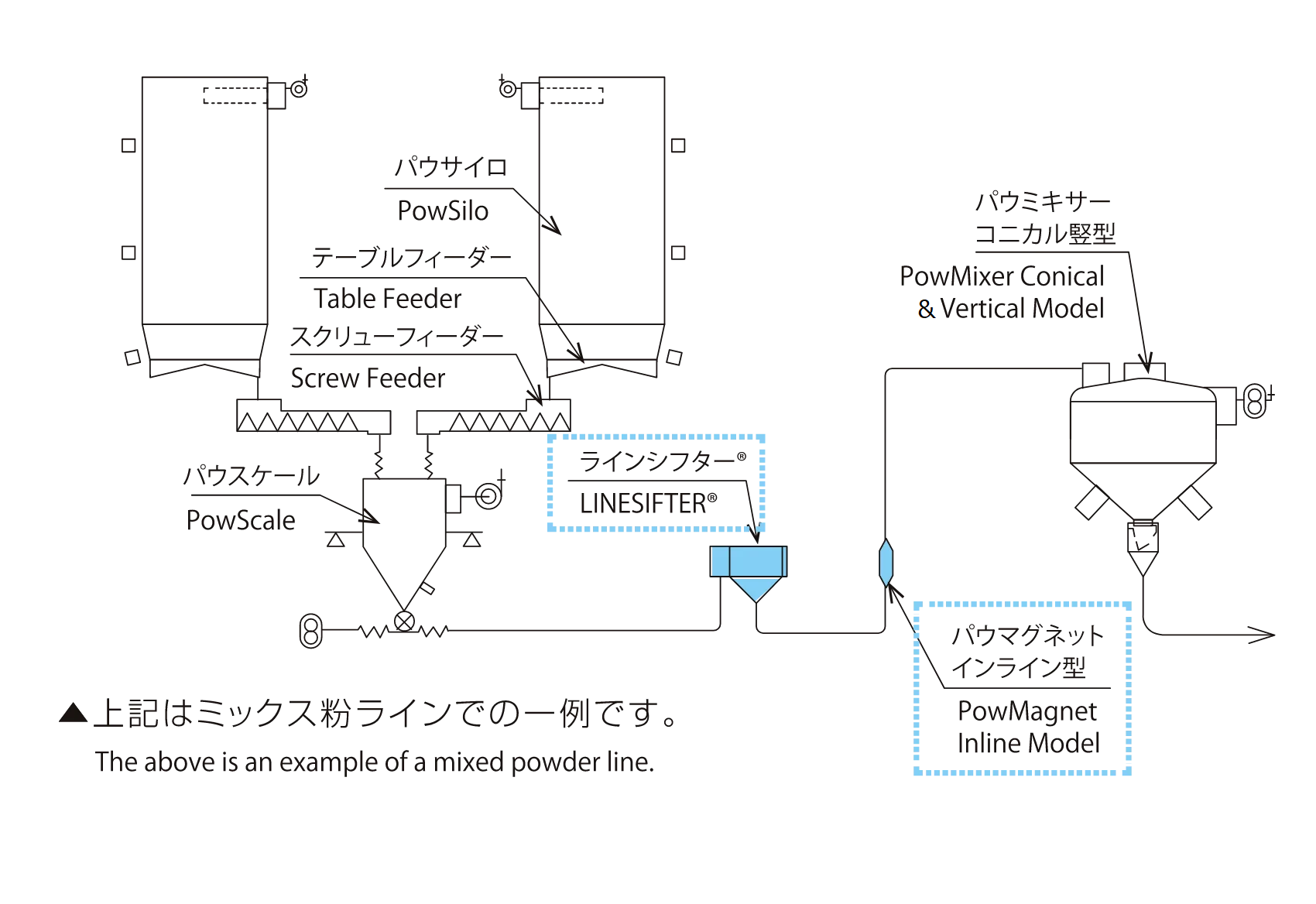

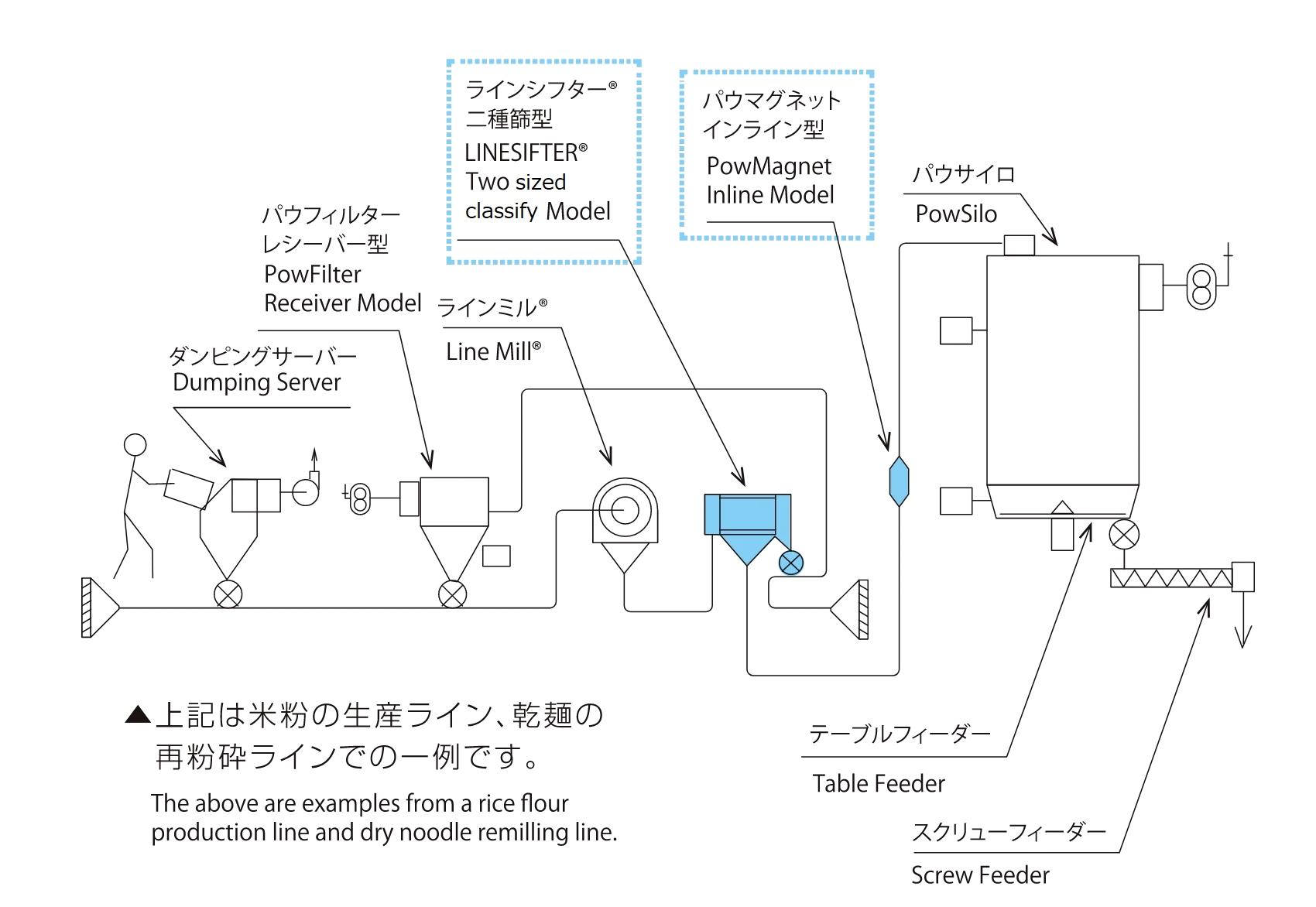

Application examples of TSUKASA's sieving machine and foreign matter removal equipment

Efficiency in discharging, weighing, and mixing stock materials

After the material is discharged from the "PowSilo" and weighed by the "PowScale," it is sent to the "LINESIFTER® Standard Model" for sifting by pneumatic conveyance. In addition, the "PowMagnet Inline Model" removes magnetic foreign matter. It is then mixed in the "PowMixer Conical Type Vertical Model" and sent to the next process.

Recycled use of classified over-size material

The material pneumatically conveyed from the "Dumping Server" is milled in the "Line Mill." After milling, the material is classified into pass and over-size material by the "LINESIFTERR Two-type Separating Model," and the pass material is sent to the "PowSilo" after removing magnetic foreign matter. The over-size material is recycled upstream for remilling.

Easy to keep clean

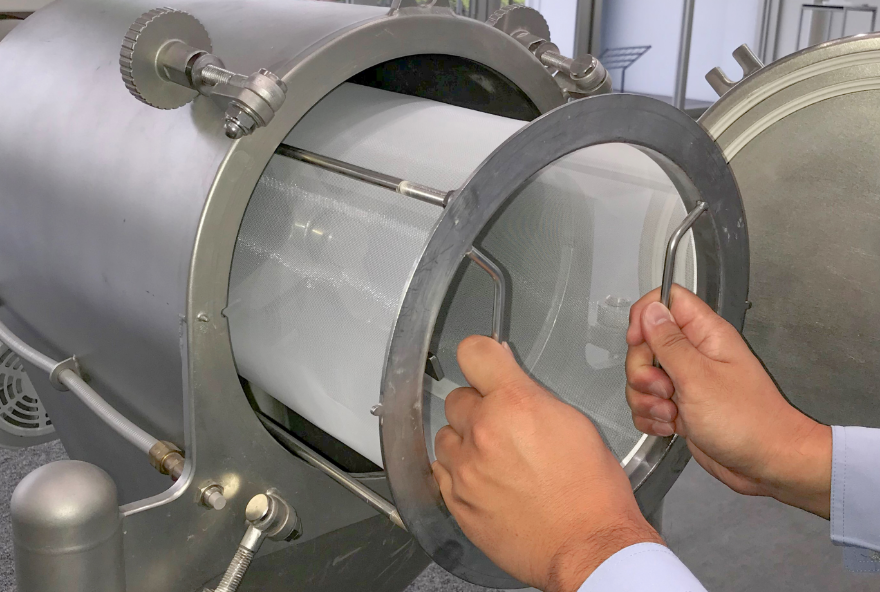

"LINESIFTER® Standard Model" is easy to maintain. Simply pull the cylindrical sieve (net) out of the main body, dust any foreign matter off, and return it to its original position. No tools are required. The structure makes it very simple to replace the spare netting compared to the conventional band type. Another option is to wash it in water to easily keep it clean.

Loosen the knob bolt

Open the door and pull out the sieve

Basic Maintenance of TSUKASA Powder Equipment

Sifter

LINESIFTER®︎ Standard Model(LS)

In-line model sifter installed in the pneumatic conveyance lineMORE >

LINESIFTER®︎︎ Two sized classify Model(LS-SP)

Sifter in the pneumatic conveyance line with the ability to classify materials into two particle sizeMORE >

PowSifter Standard Model(PSF)

In-line model sifter which is installed in chute conveyance linesMORE >

PowSifter︎ Two sized classify Model(PSF-SP)

Sifter which is installed in the chute conveyance line for classifying materials into two particle sizeMORE >

PowSifter︎ Three sized classify Model(PSF-SPW)

In-line model sifter which is installed in the chute conveyance line for classifying materials into three particle sizeMORE >

PowSifter Special Specification Example(PSF-25/70-Z)

Easiness to clean and visibility of the inside of the equipment improved by adding a side inspection port.MORE >

PowSifter Special Specification Example(PSF-15/25 GMP)

Specially designed for R&D and prototyping of pharmaceuticals and multi-ingredient applicationsMORE >

Sieve Cleaner for LINESIFTER® and PowSifter

Cleaning equipment that can clean without contaminating the surroundingsMORE >

Foreign material removal equipment

Magcap(MCP)

Magnetic foreign matter removal device which can be installed at the inspection port of chute conveyance pipesMORE >

Magcap Removable Types(MC)

Magnetic foreign matter removal device with a detachable magnet barMORE >

Magnet Spout(MS-G)

Magnetic foreign matter removal device which can be installed in chute conveyance pipesMORE >

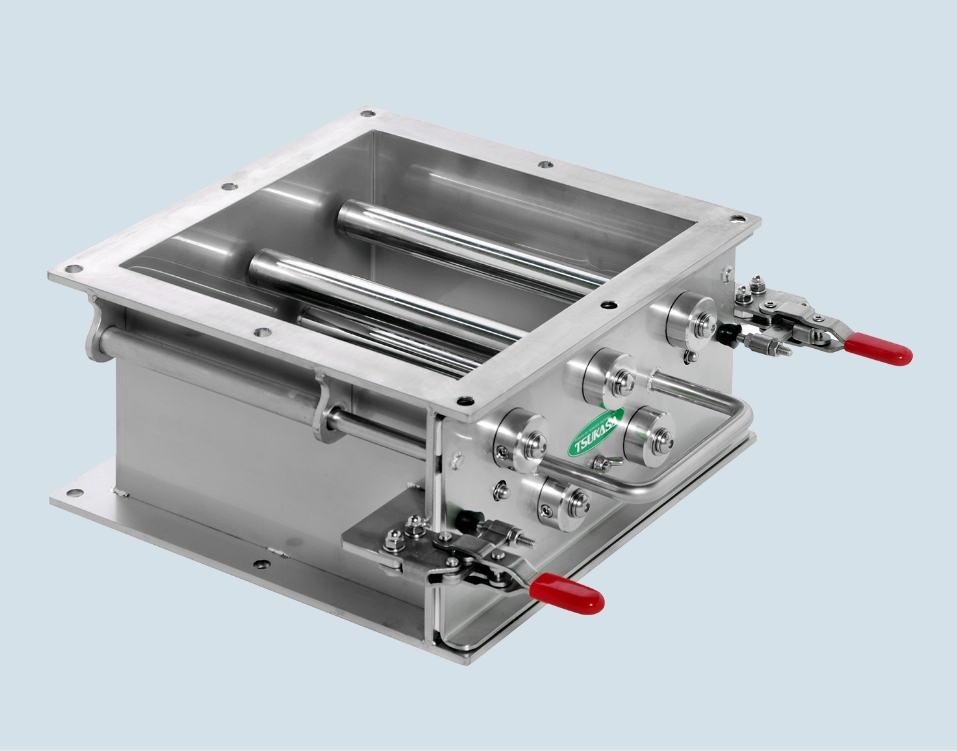

PowMagnet Gate Model(MG2)

Magnetic foreign matter removal device which can be installed at the feed/discharge port of equipment and tanksMORE >

PowMagnet Rotary Model(SRM2)

Magnetic foreign matter removal device which can deal with highly adhesive powderMORE >

PowMagnet Inline Model(NIM)

Magnetic foreign matter removal device which can be installed in the pneumatic conveyance line, etc.MORE >

PowMagnet Inline Model Bar Type(NIMB)

Magnetic foreign matter removal device with the detachable cap structureMORE >

If you want to request or download detailed information, or consult with us about technologies or ask questions about our products, contact us from this page.