Valves and Piping parts

A wide variety of valve and piping parts that have superior compatibility

A wide variety of valve and piping parts that have superior compatibility

Two-way Valves

PowChange Middle Metal touch Automatic Model(PC-MMA)

Features

⚫︎Small pressure loss, smart and light.

⚫︎Since it is ultra light, support and attachment construction are easy.

⚫︎Shaft seal is labyrinth type and dumper employs stainless metal special seal (PAT.P.), which prohibits sealing material from being mixed with powder.

⚫︎Since it is ultra light, support and attachment construction are easy.

⚫︎Shaft seal is labyrinth type and dumper employs stainless metal special seal (PAT.P.), which prohibits sealing material from being mixed with powder.

Applications

Damper allows switching of direction on flow of powders and granules.

Specifications

⚫︎Materials: Area in contact with powder...Stainless steel

Other areas...Steel (plated finish)

⚫︎Standard equipment: Pneumatic cylinder solenoid valve and cylinder switch

⚫︎Options: Explosion specifications secondary battery specifications surface treatment (adhesion prevention, curing treatment, buffed finish etc.)

Other areas...Steel (plated finish)

⚫︎Standard equipment: Pneumatic cylinder solenoid valve and cylinder switch

⚫︎Options: Explosion specifications secondary battery specifications surface treatment (adhesion prevention, curing treatment, buffed finish etc.)

Optional connection specifications

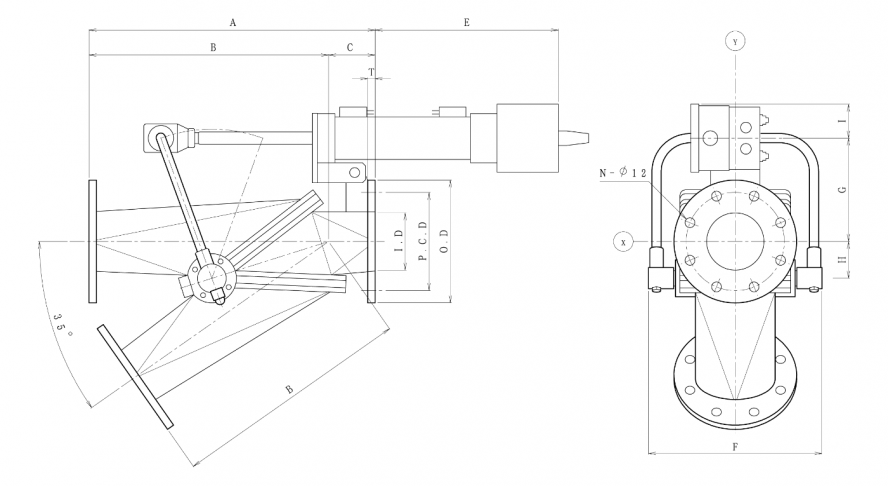

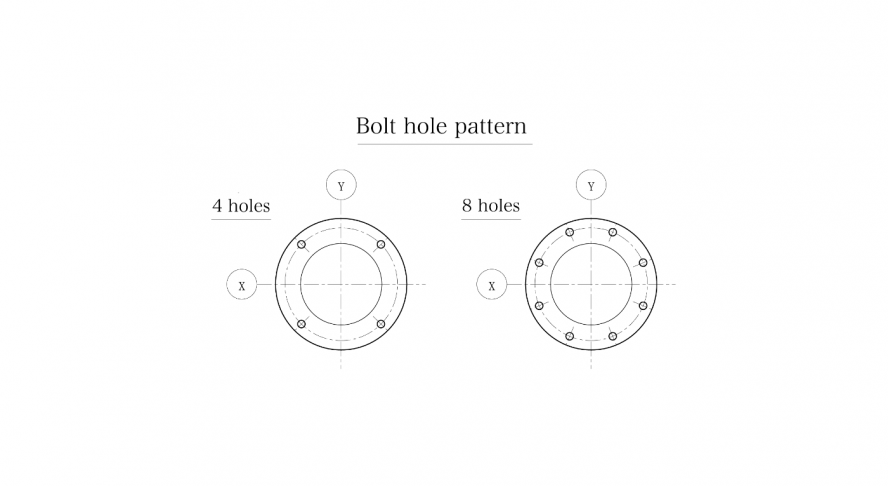

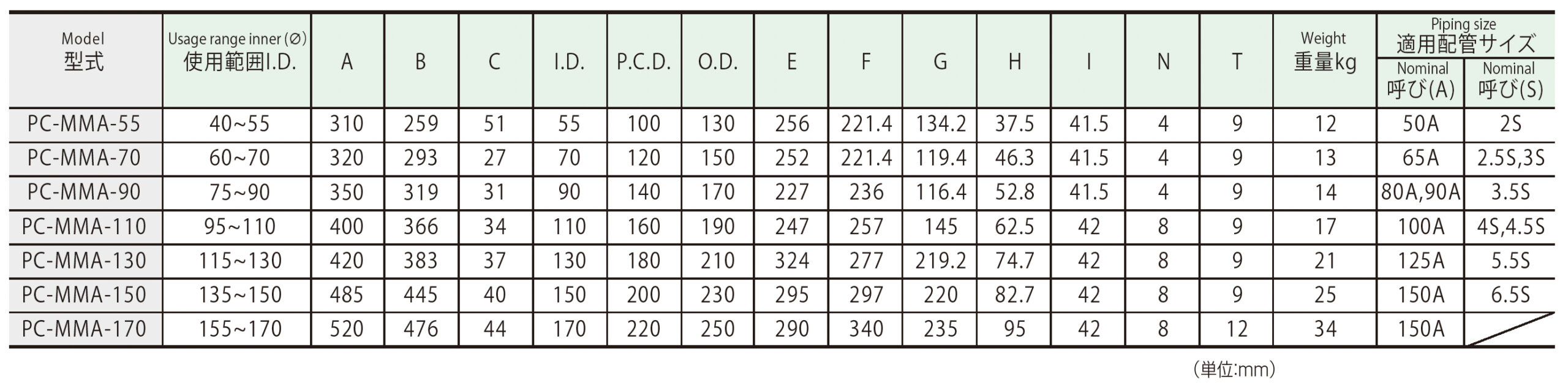

Drawings/Dimensions

⚫︎If a piping diameter other than the nominal diameters for the models listed above is required, fit using a taper.

⚫︎Mating flange (SS) and rubber packing (EPDM white) are standard.

⚫︎Please inform when you use in case of as follows.

1. When you use in suction line

2. When you use at outdoor

3. when you use for abrasive powder

⚫︎Specify the following details when ordering:

1. Model

2. Solenoid valve specifications

3. Cylinder switch voltage and quantity

4. Conveyed material and conveyance method

⚫︎Mating flange (SS) and rubber packing (EPDM white) are standard.

⚫︎Please inform when you use in case of as follows.

1. When you use in suction line

2. When you use at outdoor

3. when you use for abrasive powder

⚫︎Specify the following details when ordering:

1. Model

2. Solenoid valve specifications

3. Cylinder switch voltage and quantity

4. Conveyed material and conveyance method