Valves and Piping parts

A wide variety of valve and piping parts that have superior compatibility

A wide variety of valve and piping parts that have superior compatibility

Two-way Valves

PowChange Middle Automatic Model(PC-MA)

Features

⚫︎Small pressure loss, smart and light.

⚫︎Since it is ultra light, support and attachment construction are easy.

⚫︎Shaft seal is labyrinth type and damper has shoulders, which makes seal burden very small.

⚫︎Simple damper seal material replacement.

⚫︎Since it is ultra light, support and attachment construction are easy.

⚫︎Shaft seal is labyrinth type and damper has shoulders, which makes seal burden very small.

⚫︎Simple damper seal material replacement.

Applications

Damper allows switching of direction on flow of powders and granules.

Specifications

⚫︎Materials:

Area in contact with powder...Stainless steel

Other areas...Steel (plated finish)

⚫︎Damper Seal Materials: Polyester elastomer

⚫︎Standard equipment: Pneumatic cylinder, solenoid valve, and cylinder switch

⚫︎Options: Explosion specifications, secondary battery specifications, surface treatment (adhesion prevention, curing treatment, buffed finish etc.)

Area in contact with powder...Stainless steel

Other areas...Steel (plated finish)

⚫︎Damper Seal Materials: Polyester elastomer

⚫︎Standard equipment: Pneumatic cylinder, solenoid valve, and cylinder switch

⚫︎Options: Explosion specifications, secondary battery specifications, surface treatment (adhesion prevention, curing treatment, buffed finish etc.)

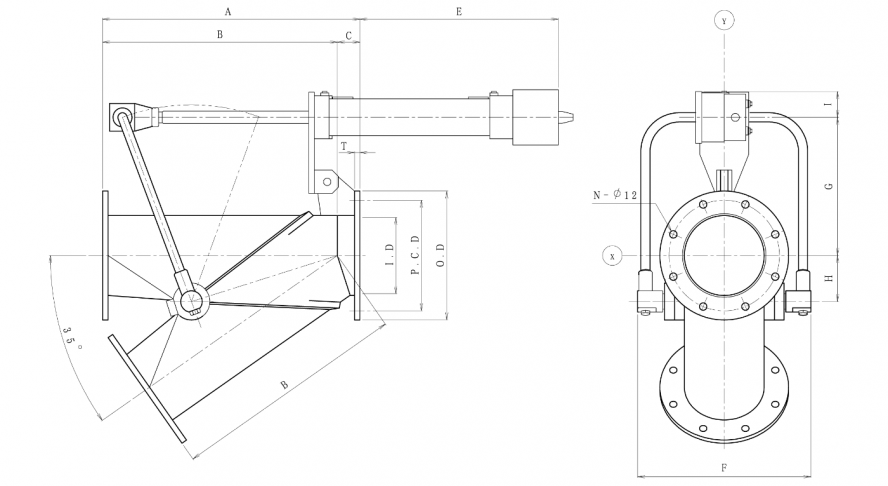

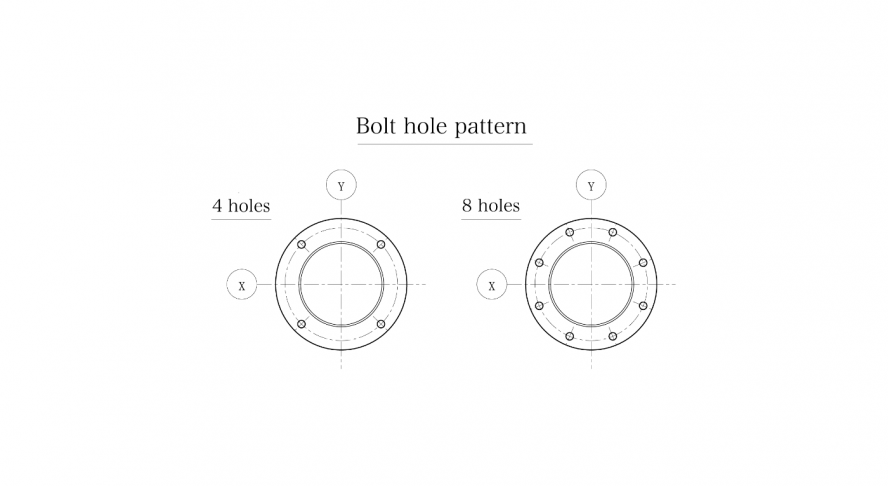

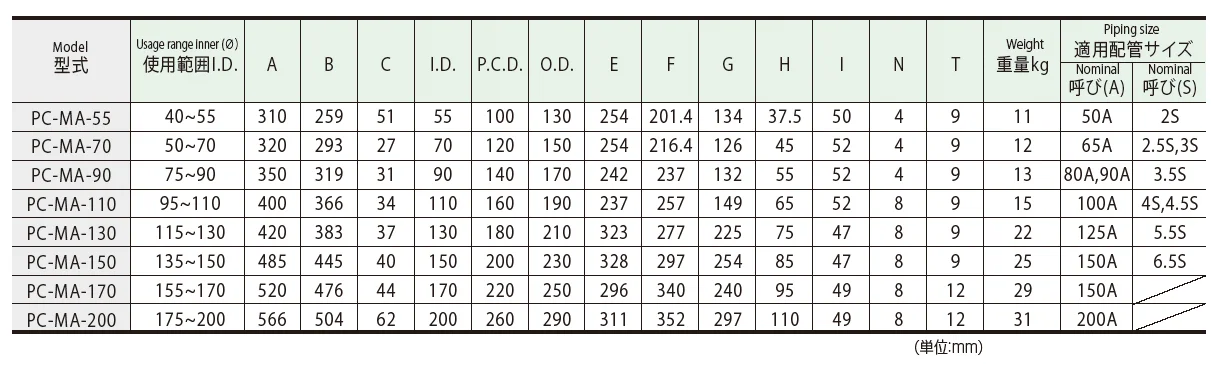

Drawings/Dimensions

⚫︎If a piping diameter other than the nominal diameters for the models listed above is required, fit using a taper.

⚫︎Mating flange (SS) and rubber packing (EPDM white) are standard.

⚫︎Please inform when you use in case of as follows.

1. When you use in suction line.

2. When you use at outdoor.

3. when you use for abrasive powder.

⚫︎Specify the following details when ordering:

1. Model

2. Solenoid valve specifications

3. Cylinder switch voltage and quantity

4. Conveyed material and conveyance method

⚫︎Mating flange (SS) and rubber packing (EPDM white) are standard.

⚫︎Please inform when you use in case of as follows.

1. When you use in suction line.

2. When you use at outdoor.

3. when you use for abrasive powder.

⚫︎Specify the following details when ordering:

1. Model

2. Solenoid valve specifications

3. Cylinder switch voltage and quantity

4. Conveyed material and conveyance method