Case Studies

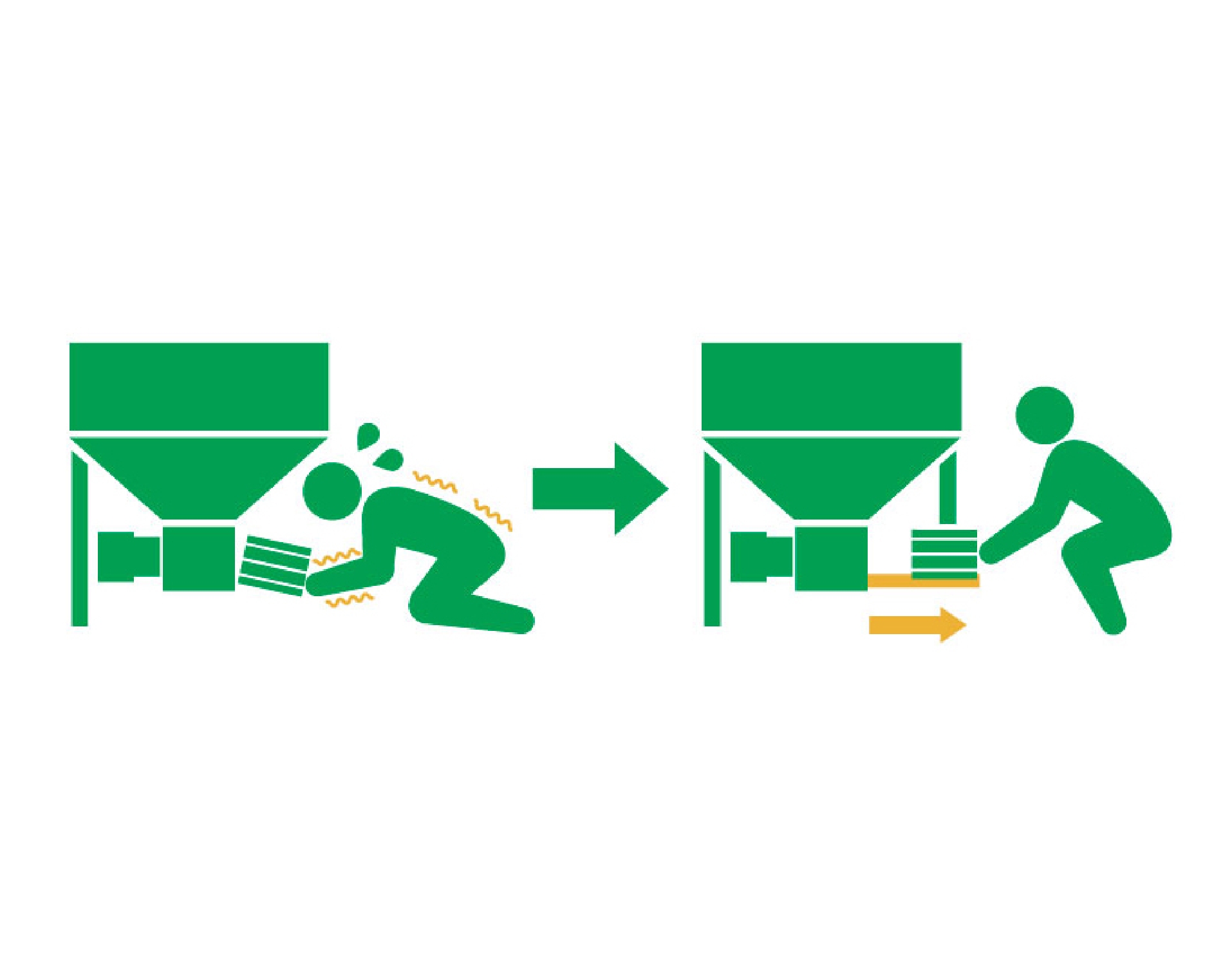

Disassembling and cleaning the sifter is now possible even for new employees

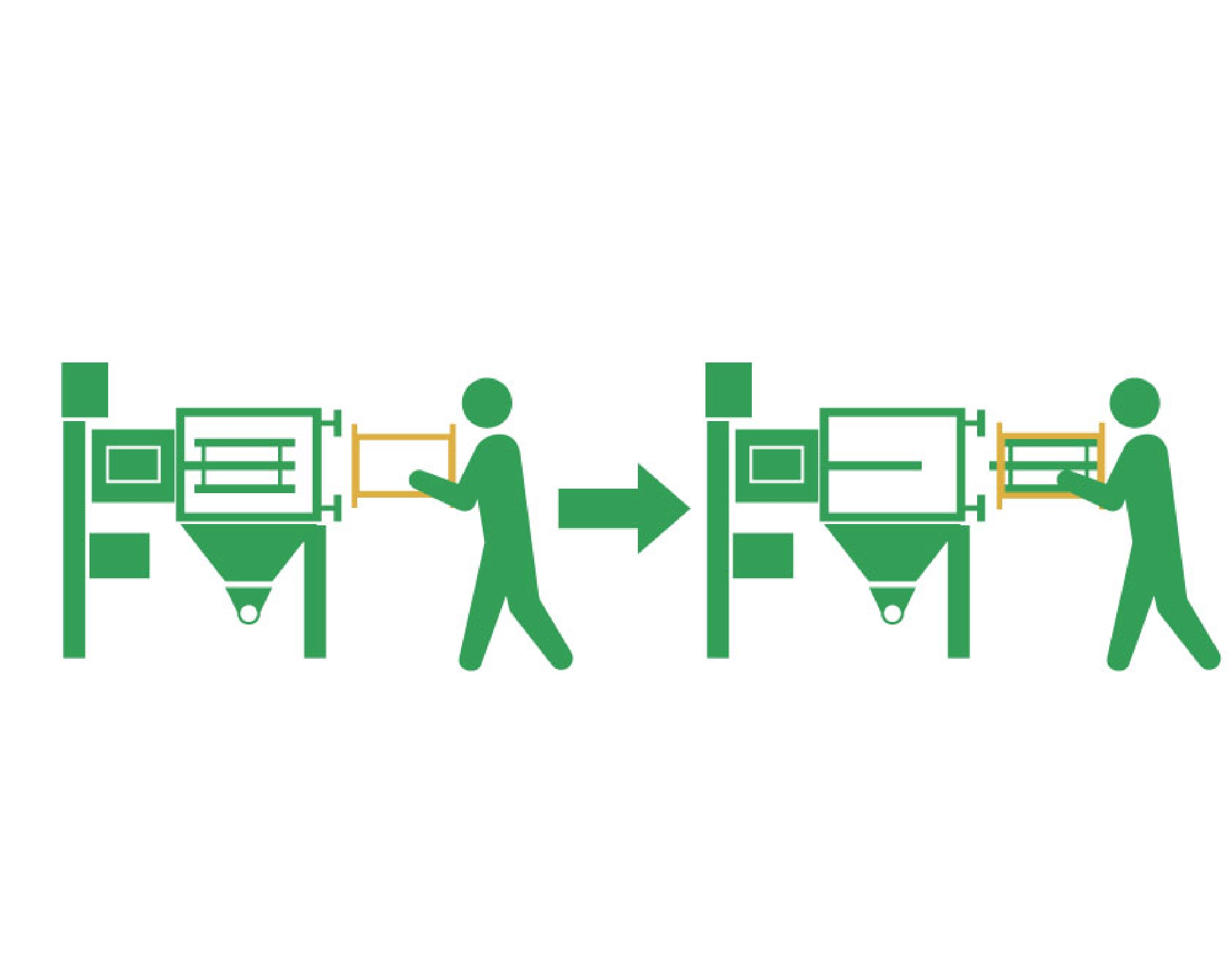

Development of a jig that enables easy removal and refitting of the rotor

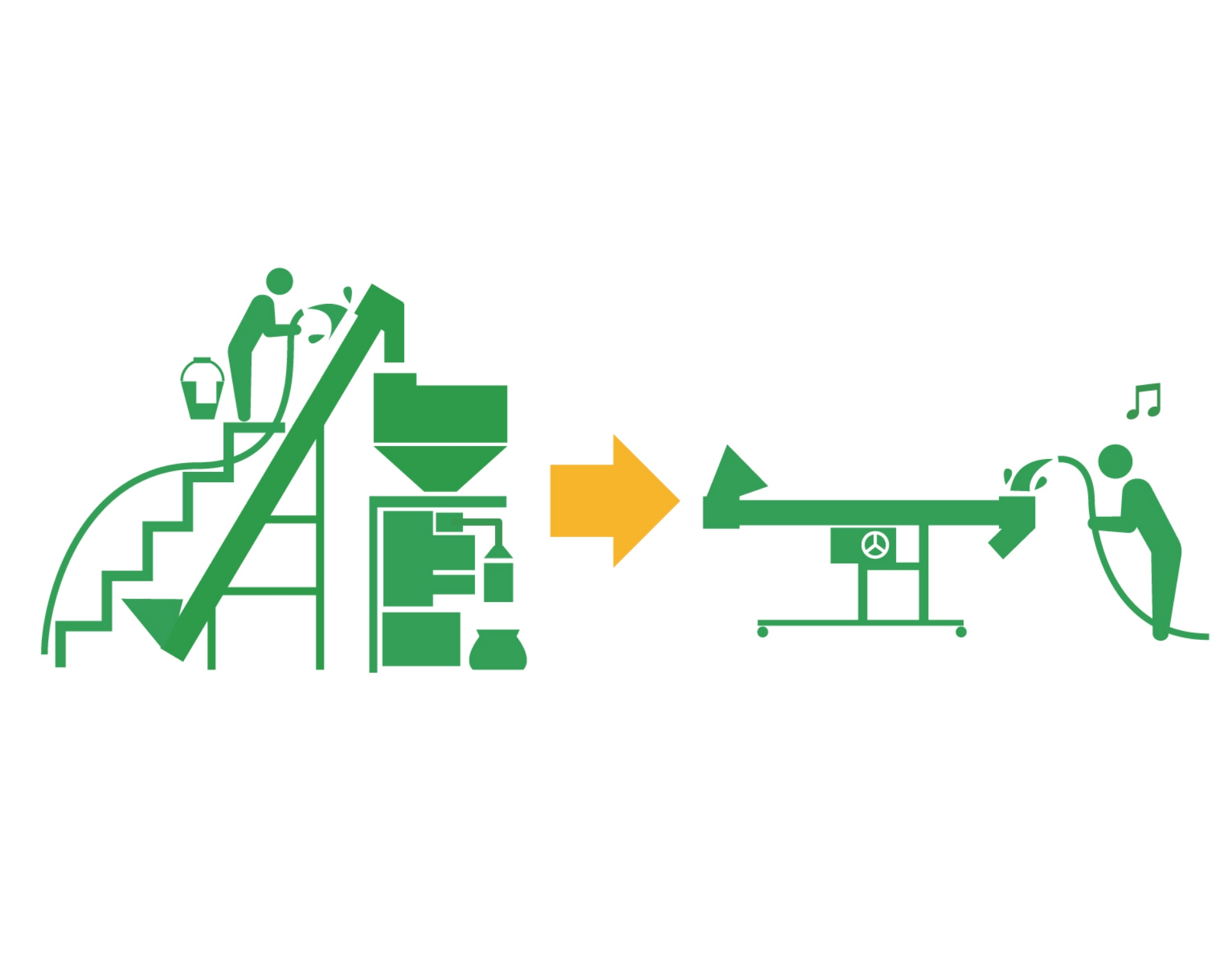

Screw Feeder Tilt Adjustable With Handle

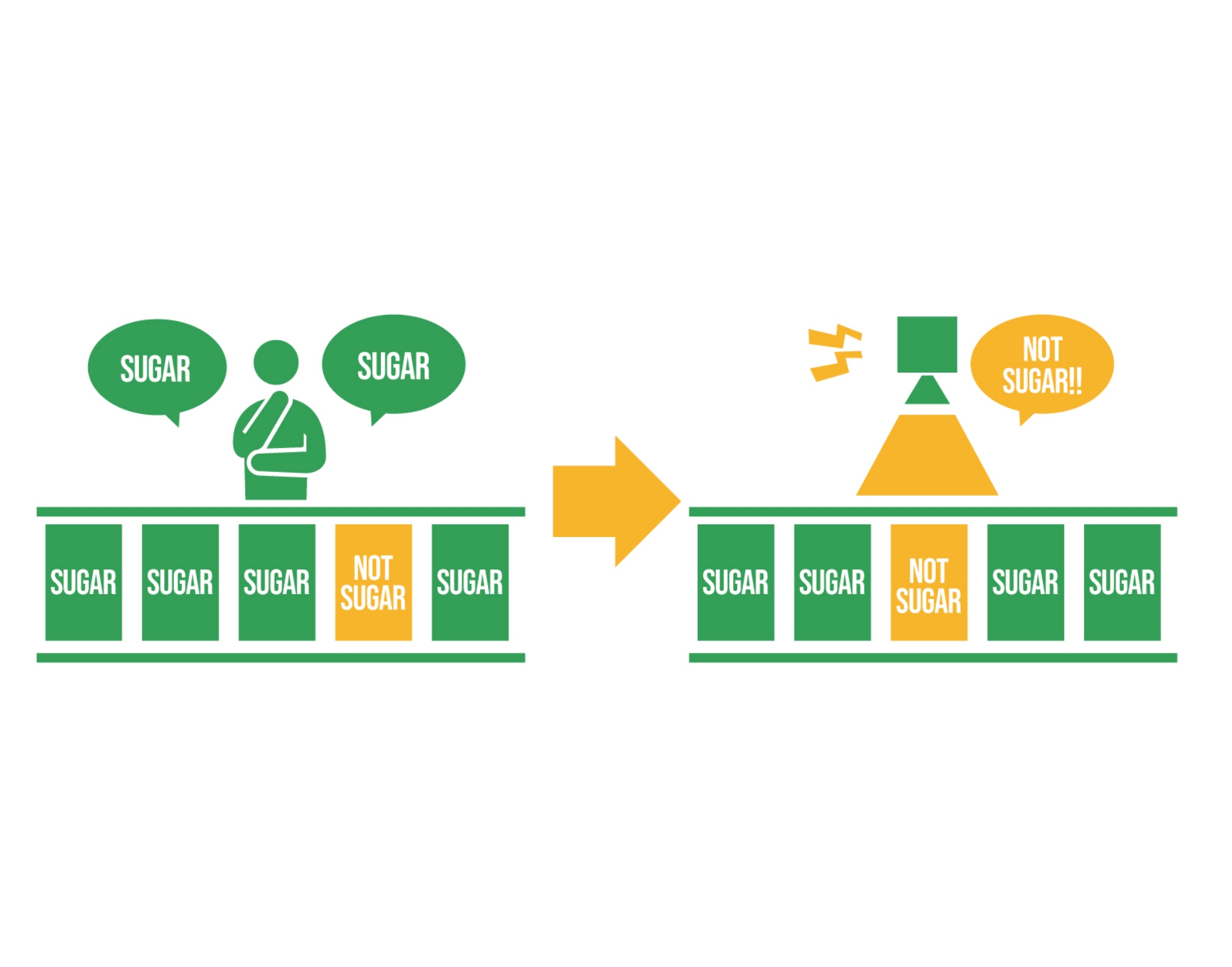

Image recognition shuts out erroneous feeding of powder raw materials

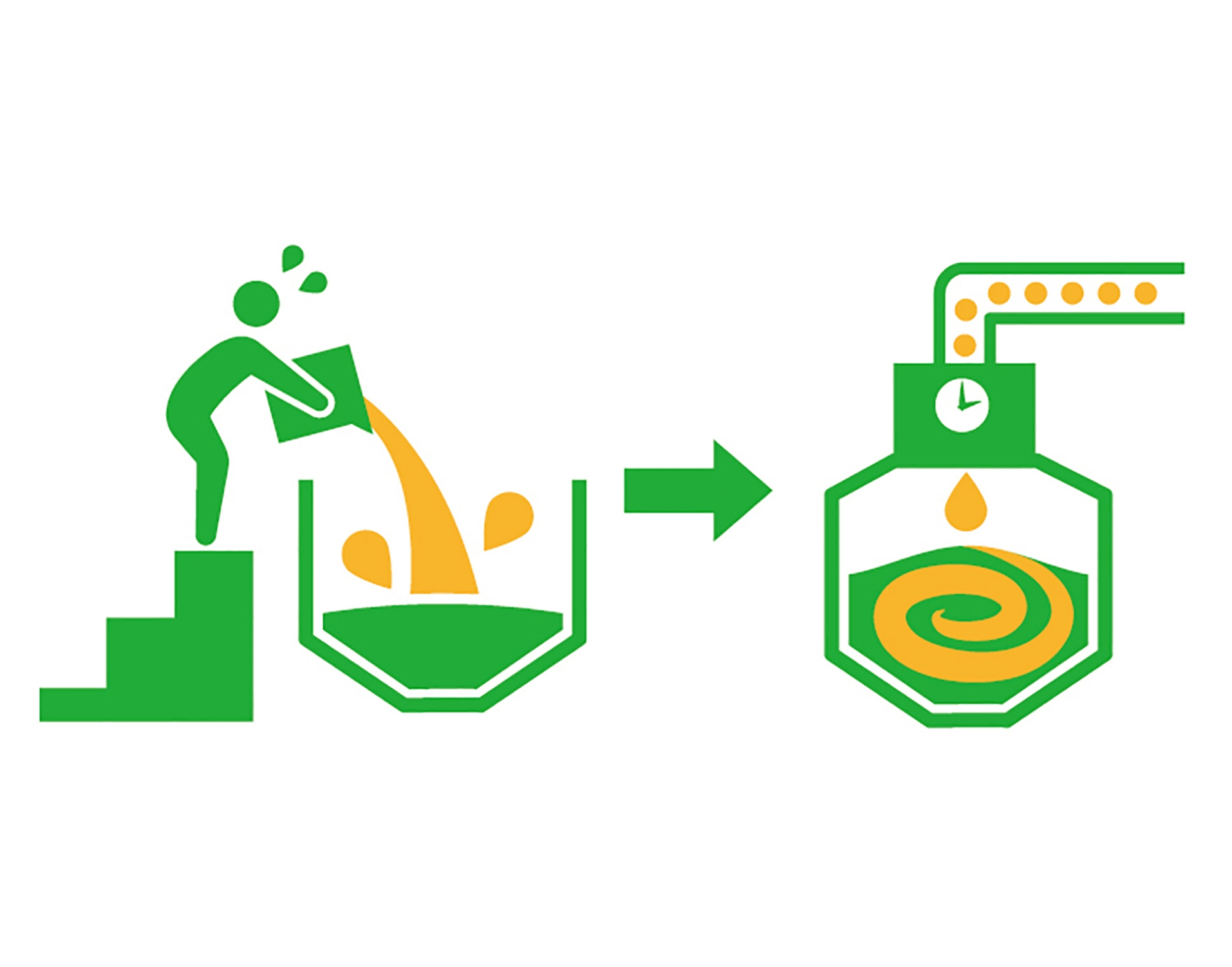

Automated liquid addition in the mixer and facilitated easy washing

Launch of a new factory utilizing an automated warehouse system

Updated “old equipment used for many years,” including those related to supplemental materials

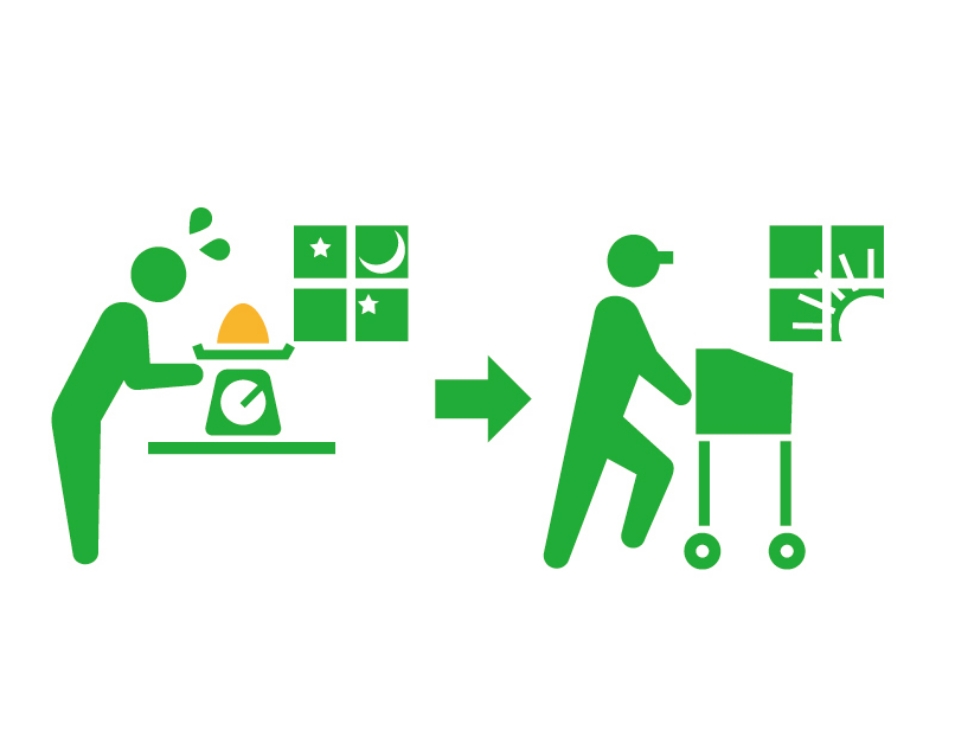

Automatic weighing with high efficiency and space saving

にあわせて切換弁を仕様変更.png)

Change in specifications of switching valve to conform with CE (EU standard)

Change in specifications to a switching valve that can be used in the secondary battery manufacturing equipment

Promotion of tool-less disassembly and water-washing of automatic bag-opening equipment

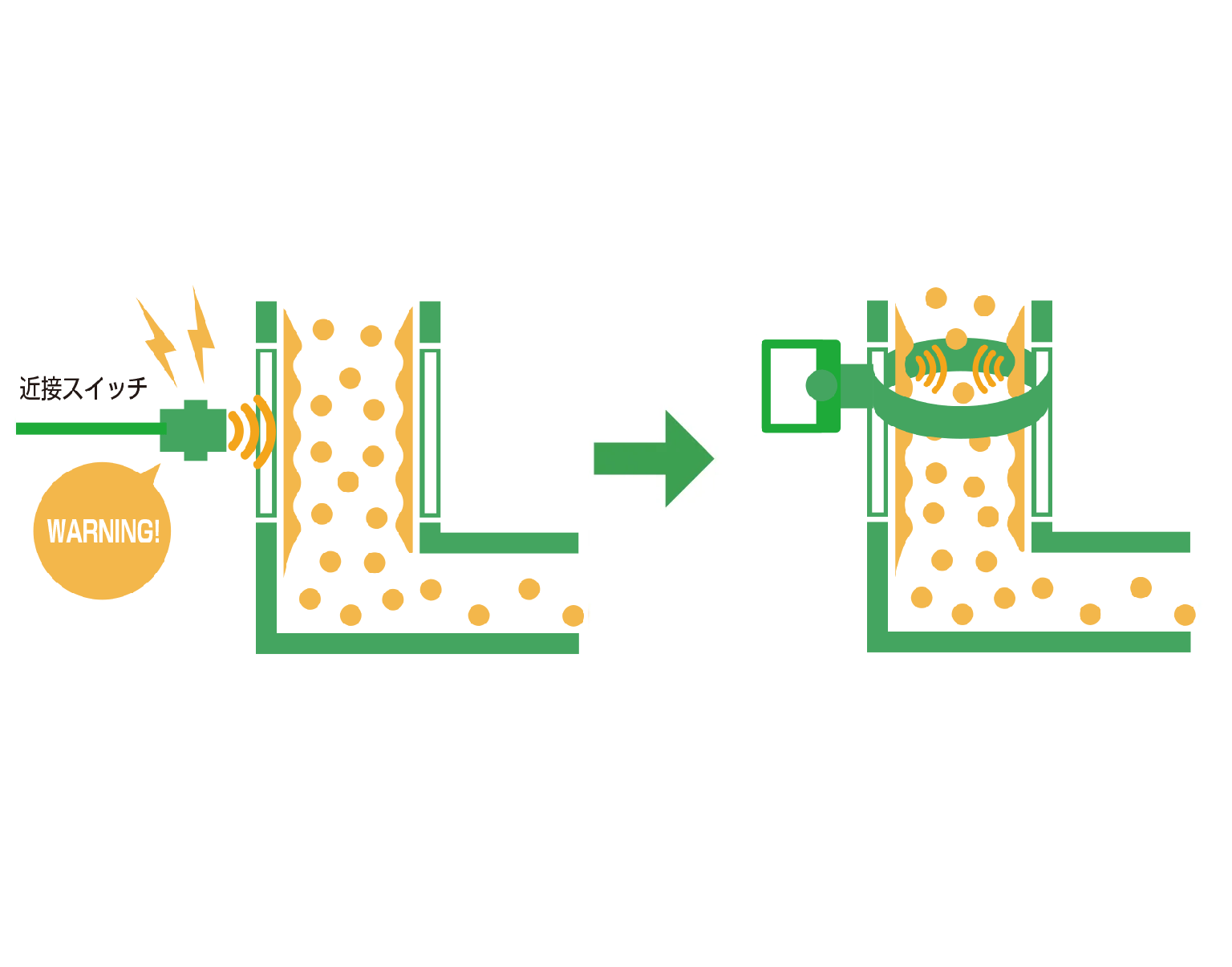

Elimination of Erroneous Detections of Wheat Flour Spouting Inside Piping