Case Studies

Case Examples

Two models have been developed to simplify rotor washing

Material Receiving and Powder Feeding Process

Type of Industry

Food manufacturer

Introduced Products

PowRotor FC model, PowRotor FCH model

Customer requests

Lighten the effort of rotor washing

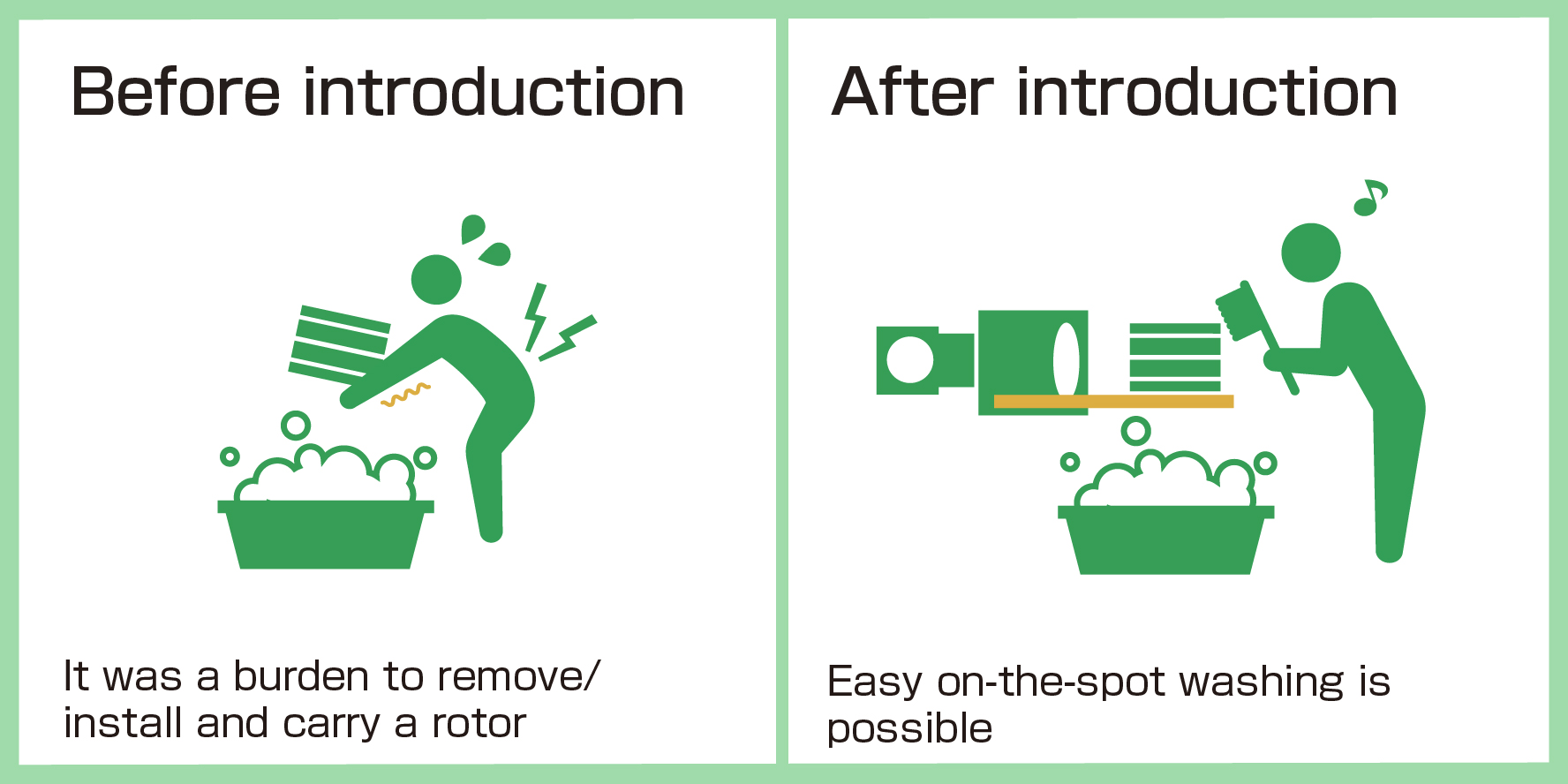

In the conventional washing of a PowRotor (quantitative feeding device), it was necessary to remove the rotor (blades) inside the main unit, carry it to the washing place, and then take it back to the installing place and reinstall it after washing. This often involved working in an unstable posture at high and low places, and a certain skill was essential for removing and reinstalling the rotor. We received a consultation about whether we could make the rotor washable on the spot, and we were requested to further simplify all of the work.

Suggestions from TSUKASA

Development of a new model specializing in ease of washing

By using multiple powder raw materials and doing some other experiments, we thoroughly pursued "ease of washing" for production sites where rotor washing is performed on a daily basis. We have newly added two devices that enable washing the rotor without requiring special skills or tools and without a heavy burden.

Washable on the spot, and no carrying required

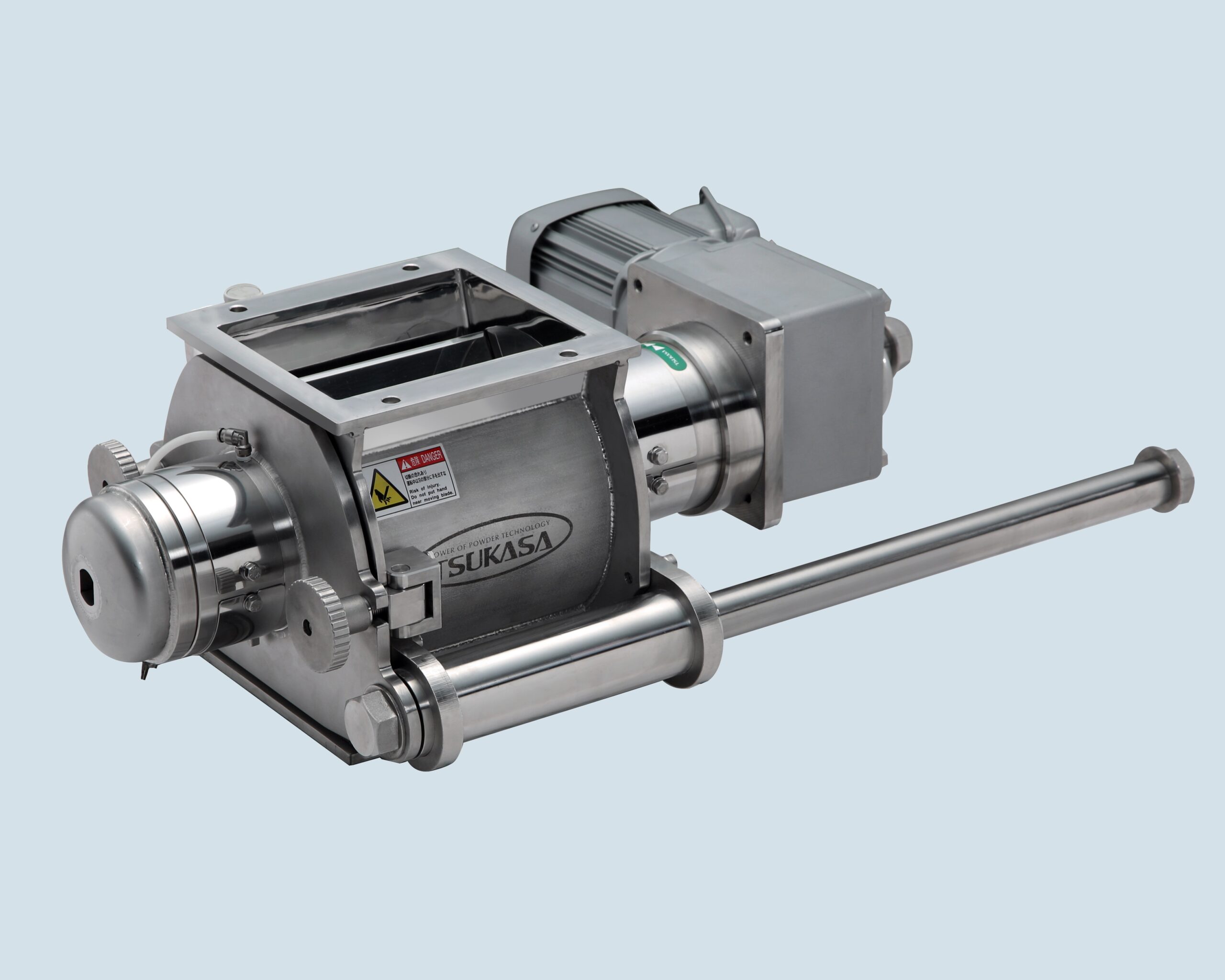

PowRotor FC (Fast Clean) model

The rotor can be pulled out manually along the guide rail simply by loosening the knob bolts. Washing can be performed on the spot. After that, simply put the rotor back and tighten the knob bolts. No tools are required, no special skills or hard work is required.

Removable without tools

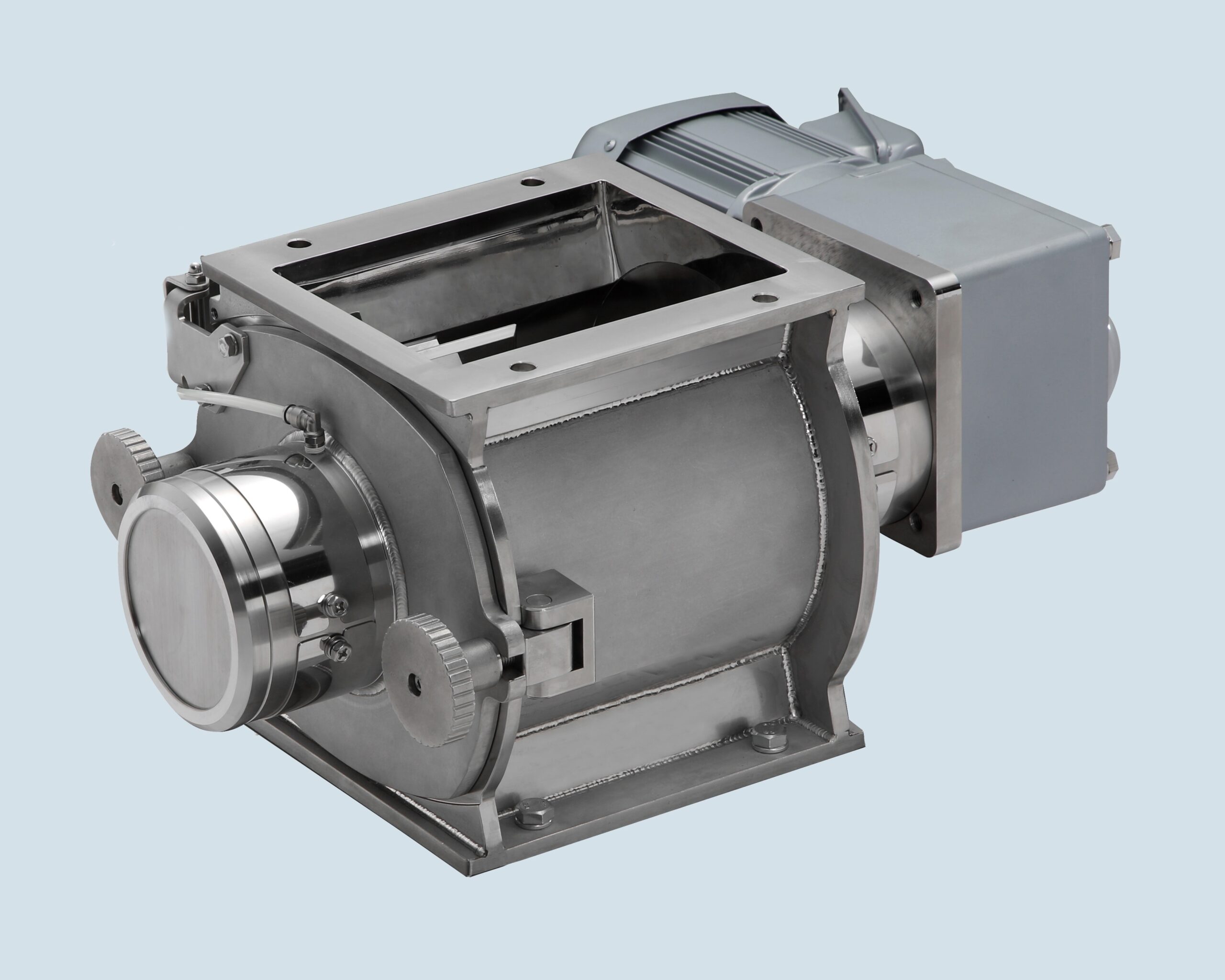

PowRotor FCH (Fast Clean [Hollow Rotor]) model

The rotor can be taken out along the guide rail simply by loosening the knob bolts. It is easier and safer to remove and reinstall the rotor itself, rather than the current model, and it is especially easy to work at high and low heights. In addition, since the size and opening/closing methods are close to those of the current model, it is easy to upgrade from the current rotor you are using.

Common benefits of FC and FCH models

⚫︎Achieved zero temporarily-placed parts

In the previous model, it was necessary to store removed bolts and other items until cleaning is completed. With the new models (FC and FCH), there is no need to remove or temporarily place parts, so there is no need to worry about the loss or fall of them.

⚫︎ Early detection of powder leaks by visualizing them

If there is a powder leakage in the rotor shaft, it can be seen during routine maintenance. You can take action before a serious problem occurs.

⚫︎ Improved washing safety

· Disassembling is possible without tools, so it is not necessary to carry tools.

· No parts need to be removed completely. This prevents the parts from being dropped or workers from falling down when carrying the parts.

· Work can be done in a more comfortable posture, greatly reducing strain on the worker.

⚫︎ Other improvement points are as follows

· Shortened removed bolt insertion work

· Simplified key alignment work of the rotor

· Simplified centering work of the rotor

· Simplified replacement of parts

In the previous model, it was necessary to store removed bolts and other items until cleaning is completed. With the new models (FC and FCH), there is no need to remove or temporarily place parts, so there is no need to worry about the loss or fall of them.

⚫︎ Early detection of powder leaks by visualizing them

If there is a powder leakage in the rotor shaft, it can be seen during routine maintenance. You can take action before a serious problem occurs.

⚫︎ Improved washing safety

· Disassembling is possible without tools, so it is not necessary to carry tools.

· No parts need to be removed completely. This prevents the parts from being dropped or workers from falling down when carrying the parts.

· Work can be done in a more comfortable posture, greatly reducing strain on the worker.

⚫︎ Other improvement points are as follows

· Shortened removed bolt insertion work

· Simplified key alignment work of the rotor

· Simplified centering work of the rotor

· Simplified replacement of parts

PowRotor/A guide to choosing a model

⚫︎What is the frequency of disassembly and washing?

Is it done every day, once a week, or at longer intervals? We recommend considering two new models for production sites with high washing frequency.

⚫︎ Is the installation location high and low?

If you want to install a PowRotor at a high position of each powder equipment or at a low position near the floor, we recommend that you consider two new models that can easily remove the rotor.

⚫︎ Where to wash the rotor?

We recommend the FC model if you want to wash it on the spot, or the FCH model if you want to remove the rotor and wash it at a dedicated place for washing.

Is it done every day, once a week, or at longer intervals? We recommend considering two new models for production sites with high washing frequency.

⚫︎ Is the installation location high and low?

If you want to install a PowRotor at a high position of each powder equipment or at a low position near the floor, we recommend that you consider two new models that can easily remove the rotor.

⚫︎ Where to wash the rotor?

We recommend the FC model if you want to wash it on the spot, or the FCH model if you want to remove the rotor and wash it at a dedicated place for washing.

For your reference

We compared the time for disassembling and reassembling between the conventional models and two new models.

We verified at the site the time required to remove the rotor from the main unit, reinsert it, and complete installation (excluding washing time).

Conventional model (TRV-LS): 3 min 35 sec

FC model: 35 sec

FCH model: 58 sec

Conventional model (TRV-LS): 3 min 35 sec

FC model: 35 sec

FCH model: 58 sec

Conventional type

PowRotor Light-weight TRV-LS

PowRotor Light-weight TRV-LS