Case Studies

Case Examples

Development of a new specification that enables you to see the inside of the sifter from the side

Sifting and Foreign-material Removal Process

Type of Industry

food / Beverage manufacturer

Introduced Products

PowSifter Special Specification

Background and problem

Occurrence of raw material loss during disassembly work for inspection and cleaning

For the "PowSifter Standard Model" installed in the chute conveyance line, the cylindrical-sieve (net) is pulled out from the inside of the main body during inspection and cleaning. A customer made the following comment: "Because the powder materials we handle are expensive, we want to prevent material loss due to the powder adhered to the inner and outer surfaces and the frame falling onto the floor when inspecting the sieve. In addition, there is a possibility that foreign matter exists on the inside of the sieve, so we want to eliminate the possibility that it will enter inline during inspection."

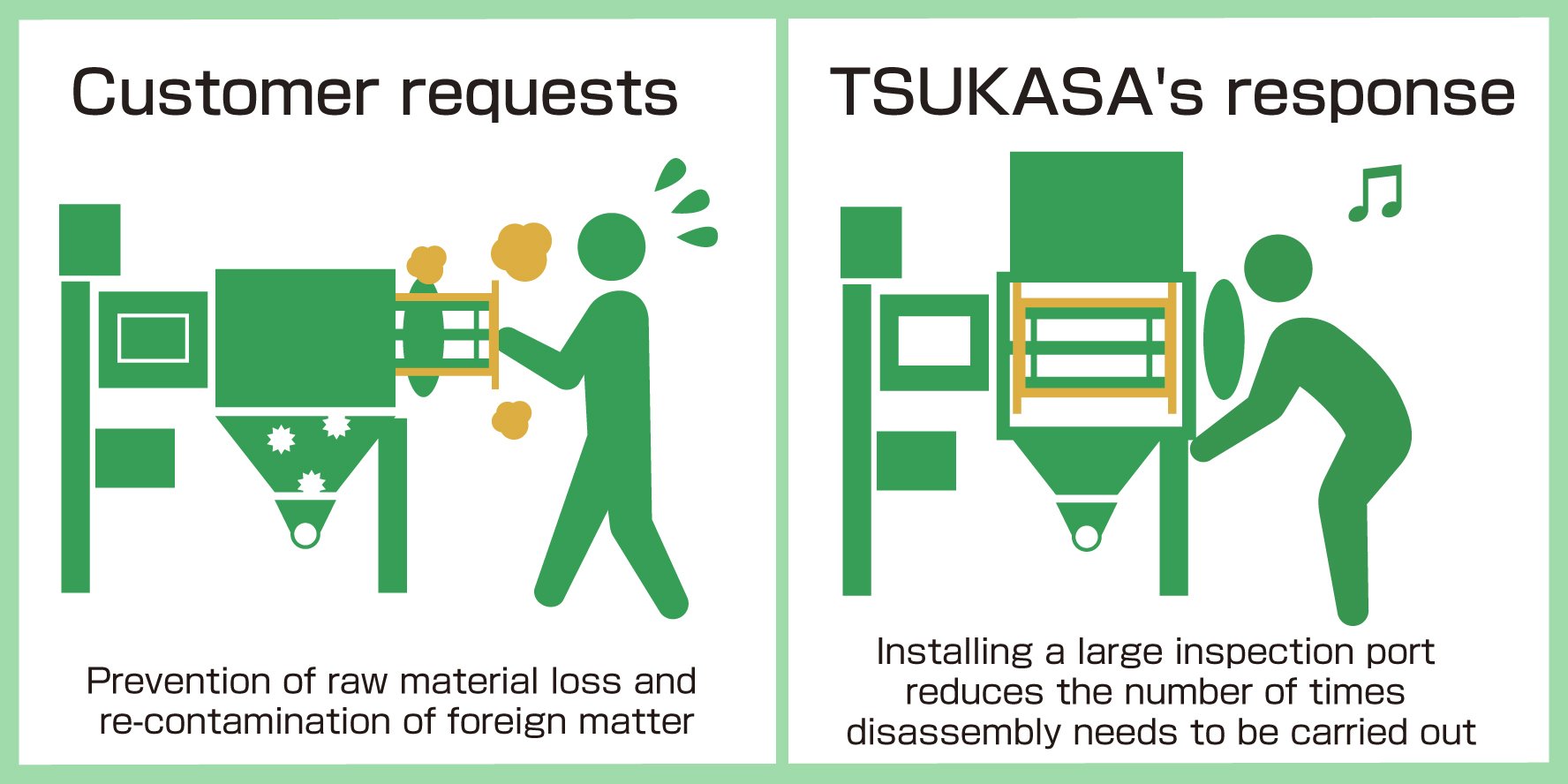

Customer requests

In the movement of pulling out the sieve from the main body

・We do not want to drop even a small amount of powder on the floor

・ We do not want foreign matter that been sieved out to get remixed in with the raw material

・We do not want to drop even a small amount of powder on the floor

・ We do not want foreign matter that been sieved out to get remixed in with the raw material

TSUKASA’s response

A large inspection port makes it possible to see from the side

We thought that we could meet the above request by making it visible from the side without pulling out the sieve.

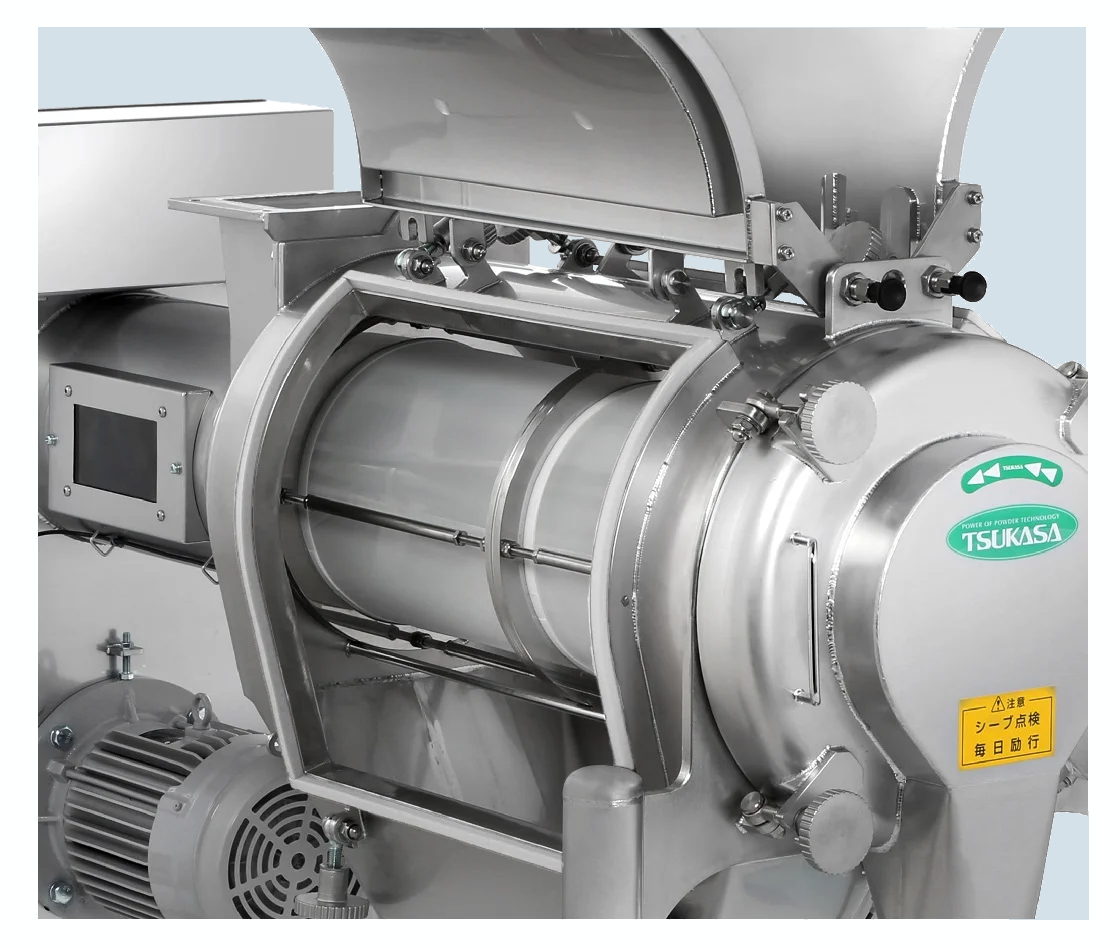

Developed the "PowSifter Special Specification"

Two large gull-wing-type inspection ports are installed on the sides, and a special specification has been developed that makes it possible to check for tearing of the sieve from the outside. By reducing the number of times the sieve is pulled out for inspection and cleaning, the resulting material loss is prevented.

Results of introduction

⚫︎Contributes to the reduction of raw material loss

It is not necessary to pull out the sieve for each inspection and cleaning, and it is possible to prevent raw material loss due to powder falling on the floor and re-contamination of foreign matter.

⚫︎Easy to inspect and clean

Opening and closing the inspection port doesn’t require any tools. Carrying out daily inspections is easier because tearing can be confirmed without the need to pull out the sieve. In addition, the main body and parts can be water-washed as a standard.

⚫︎Safety performance is even better

While the inspection port is in an open state, a holding stopper and safety proximity switch are installed to ensure the safety of workers.

It is not necessary to pull out the sieve for each inspection and cleaning, and it is possible to prevent raw material loss due to powder falling on the floor and re-contamination of foreign matter.

⚫︎Easy to inspect and clean

Opening and closing the inspection port doesn’t require any tools. Carrying out daily inspections is easier because tearing can be confirmed without the need to pull out the sieve. In addition, the main body and parts can be water-washed as a standard.

⚫︎Safety performance is even better

While the inspection port is in an open state, a holding stopper and safety proximity switch are installed to ensure the safety of workers.

TSUKASA's basic stance

We strive towards "ease of disassembly" and "making disassembly unnecessary" together

In the inspection and cleaning of powder equipment, we are always thinking about how easy it can be to disassemble and wash, and whether there is work that can be handled without disassembling the equipment every time. The "PowSifter Special Specification" equipped with a gull-wing-type inspection port is an example of how TSUKASA's basic stance became a concrete product.