Case Studies

Case Examples

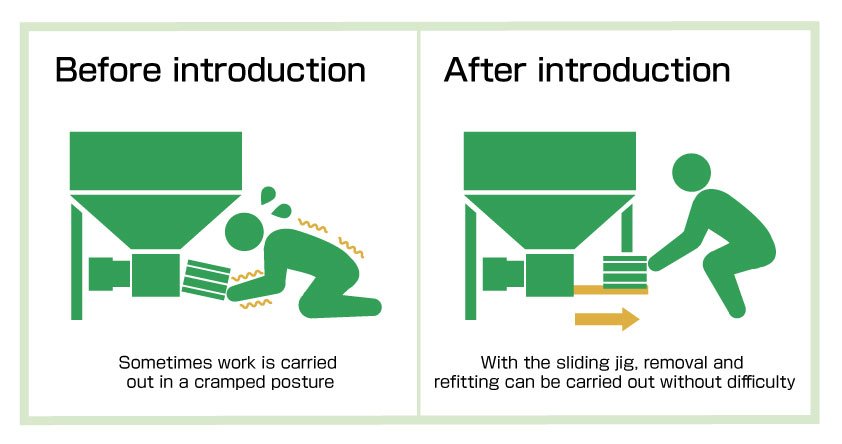

Development of a jig that enables easy removal and refitting of the rotor

Handling Process

Type of Industry

Food manufacturer

Introduced Products

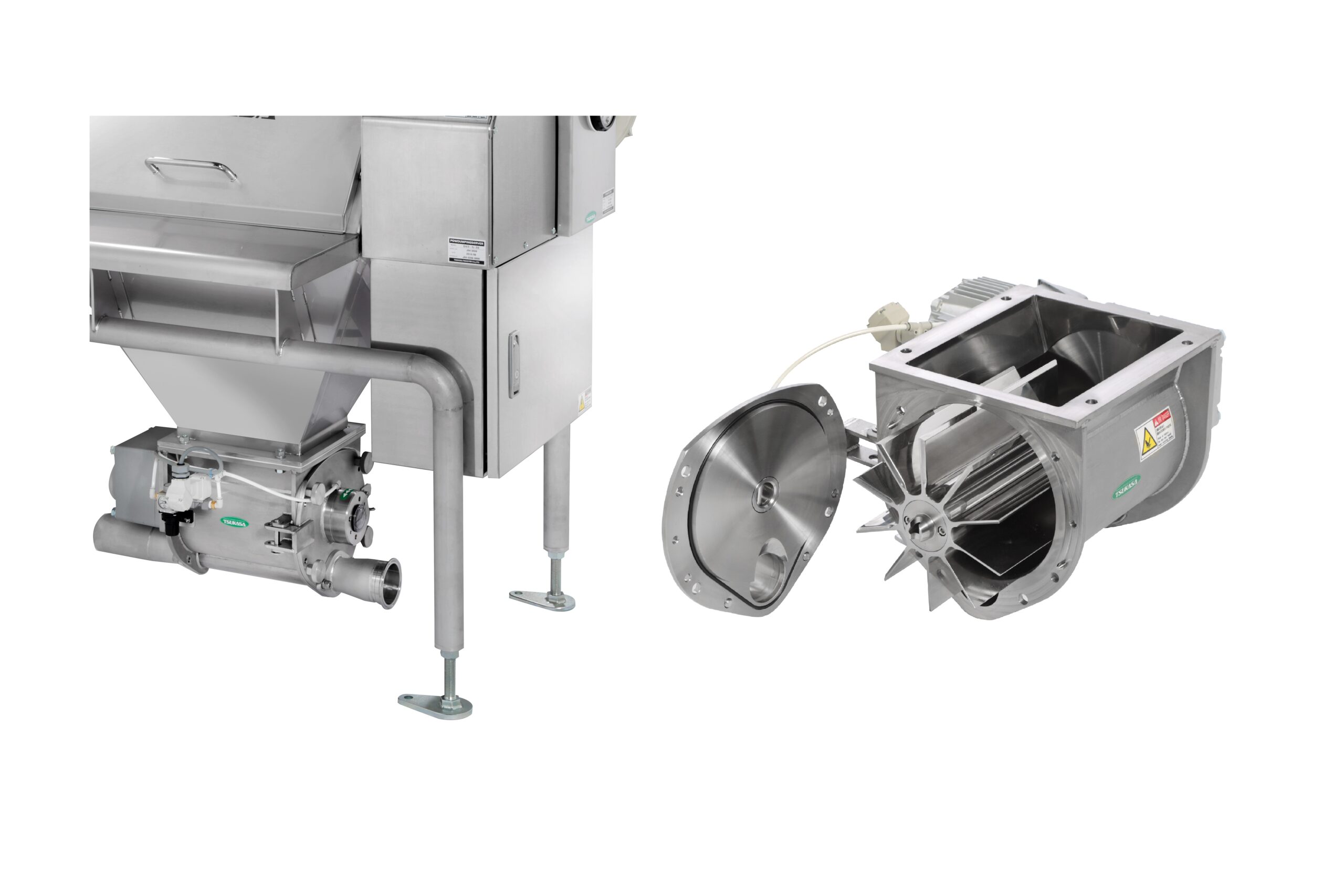

Rotor slider (PowRotor replacement jig) *Patent pending

Background and problem

I want to reduce the burden of removing and refitting heavy rotors

In plants that use several types of powder materials, PowRotor (constant supply equipment) is frequently cleaned. During cleaning, removing the rotor (blades) inside the main unit required pulling it out with both hands, and weighed up to 17 kg. As such, there was a need to prevent accidents such as damage from dropping the equipment and injuries. These occurred while working with an unsteady posture, or when unexperienced workers were doing the job. It also required a certain level of skill to put the rotor back into place after cleaning.

TSUKASA’s response

Newly designed sliding jig that can be removed and refitted without the weight burden

After receiving consultations from customers, TSUKASA proceeded with the design of the rotor removal and refitting jig.

◎ As a prerequisite

・Even if you are not an expert, you can easily handle it without making mistakes

・Can be used as a retrofit to the PowRotor currently in use

・When the rotor comes off, you don't feel the weight all at once

・The rotor enters smoothly even when it is installed

With this in mind, we adopted a method in which a sliding jig is attached to the current PowRotor and the rotor slides and moves over it.

◎ As a prerequisite

・Even if you are not an expert, you can easily handle it without making mistakes

・Can be used as a retrofit to the PowRotor currently in use

・When the rotor comes off, you don't feel the weight all at once

・The rotor enters smoothly even when it is installed

With this in mind, we adopted a method in which a sliding jig is attached to the current PowRotor and the rotor slides and moves over it.

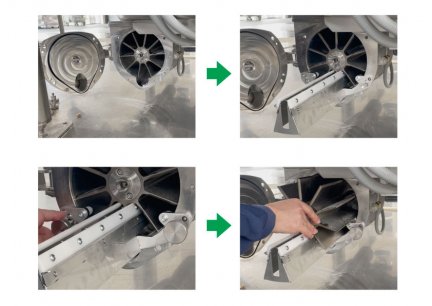

Use procedure for rotor slider (when removed)

Smooth removal and refitting even for non-expert users with a simple procedure

(1) Remove the bolts and open the inspection door

(2) Remove the bolt in the center of the rotor

(3) Adjust the angle of the rotor according to the groove of the slider

(4) Insert the slider and secure it with the supplied special bolts

(5) Pull out the rotor from the inside of the main unit

(6) When it hits the stopper, remove it upwards

(2) Remove the bolt in the center of the rotor

(3) Adjust the angle of the rotor according to the groove of the slider

(4) Insert the slider and secure it with the supplied special bolts

(5) Pull out the rotor from the inside of the main unit

(6) When it hits the stopper, remove it upwards

Results of introduction

⚫︎Now it’s easy for anyone to carry out removal and refitting work without making mistakes

Even if you are not an expert or skilled worker, you can now easily carry out removal and refitting work with the guidance of the slider.

⚫︎Even safer with the adoption of a stopper

A stopper has been installed so that the rotor stops immediately before it disengages from the main body, enabling the operator to calmly bear the weight.

⚫︎Eliminates concerns about damage to the rotor

The sliding type mechanism minimizes contact (rattling) with the inside of the main unit when reinstalling the rotor. This also contributes to maintaining the quality and extending the life of the rotor.

⚫︎No changes or modifications to the current PowRotor

There is no need to prepare any parts other than the rotor slider, or make any changes or modifications to the current PowRotor. In terms of the bolt that secures the slider, it was designed so that the bolt from the current inspection door can also be used.

*Some models are different.

Even if you are not an expert or skilled worker, you can now easily carry out removal and refitting work with the guidance of the slider.

⚫︎Even safer with the adoption of a stopper

A stopper has been installed so that the rotor stops immediately before it disengages from the main body, enabling the operator to calmly bear the weight.

⚫︎Eliminates concerns about damage to the rotor

The sliding type mechanism minimizes contact (rattling) with the inside of the main unit when reinstalling the rotor. This also contributes to maintaining the quality and extending the life of the rotor.

⚫︎No changes or modifications to the current PowRotor

There is no need to prepare any parts other than the rotor slider, or make any changes or modifications to the current PowRotor. In terms of the bolt that secures the slider, it was designed so that the bolt from the current inspection door can also be used.

*Some models are different.

TSUKASA's basic stance

We pursue ease of maintenance for all powder equipment

At TSUKASA, we aim to "make cleaning and washing easy, safe, and secure" for all powder equipment. The rotor slider is a product that takes TSUKASA's philosophy one step further.