Case Studies

Case Examples

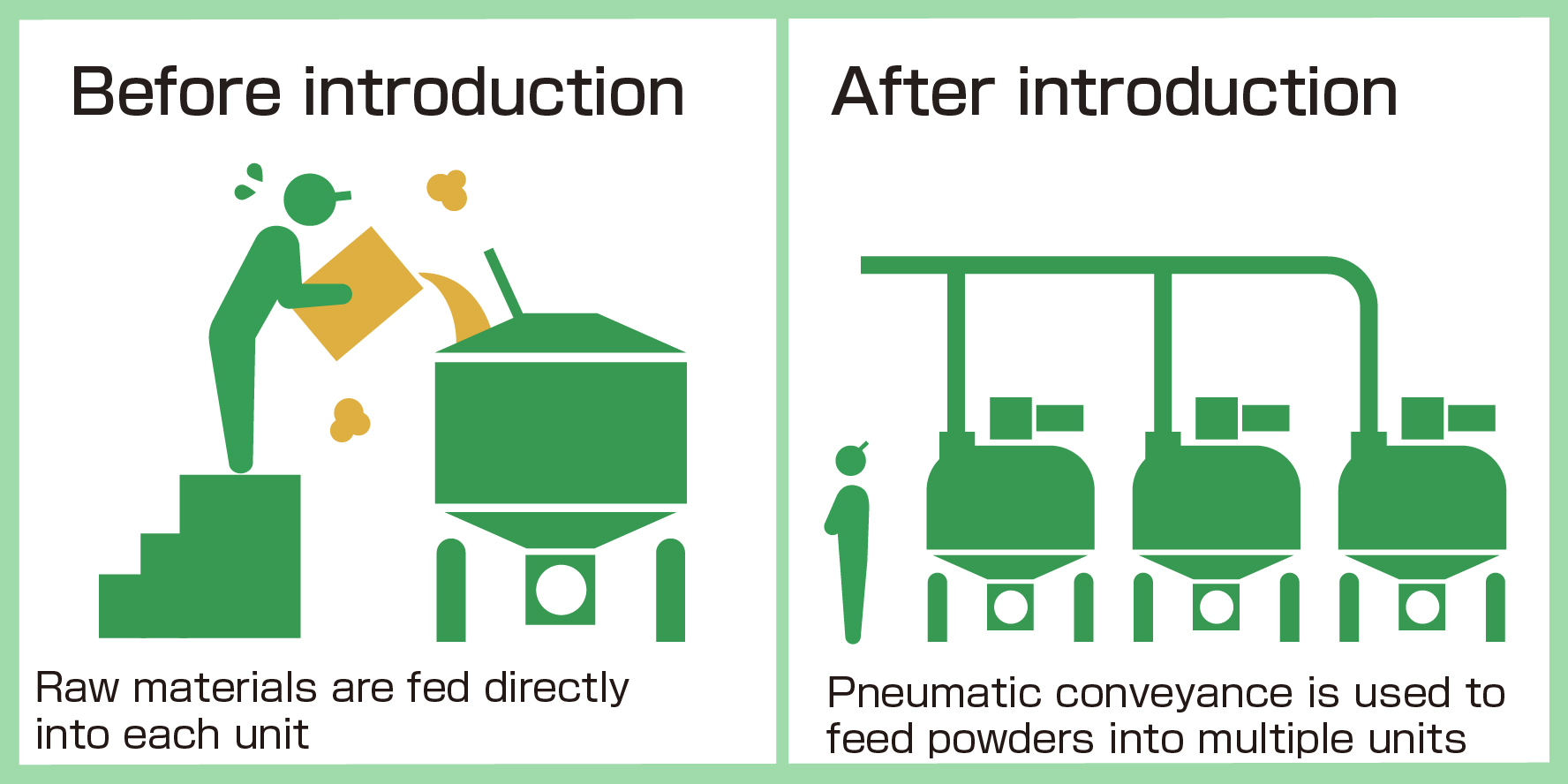

Improved direct feeding of raw materials into the dough mixer

Material Receiving and Powder Feeding Process

Type of Industry

Bread making company

Introduced Products

Pneumatic conveyor piping, cloth silos

Customer requests

Efficient feeding of powders into multiple mixers!

A customer said "The direct feeding of raw materials into the mixer for kneading bread dough is a burden on workers. Dust scattering and foreign matter contamination at the time of feeding are also worrisome. We also want to increase the number of mixers in order to improve productivity. Do we have to add some kind of equipment to each of the multiple mixers in order to automate and streamline all of these?"

Suggestions from TSUKASA

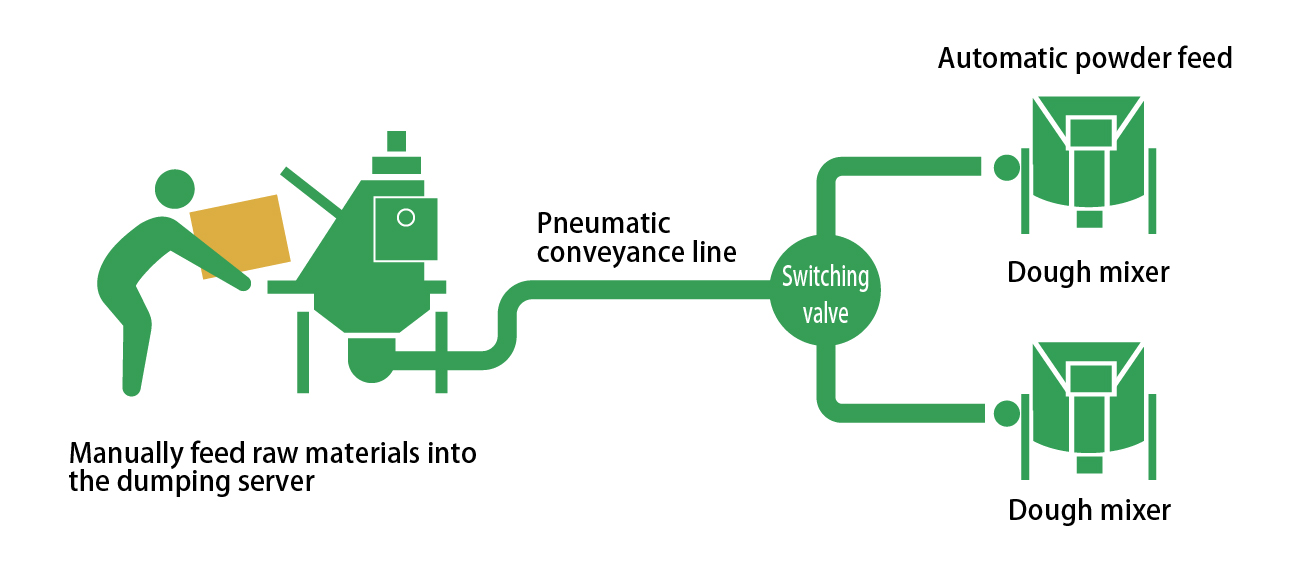

■Plan1 "One-to-many" raw-material feeding through pneumatic conveyor piping

We proposed that pneumatic conveyor piping should be used to connect the receiving of raw materials at the "dumping server" to the mixer. In this way, raw materials can be fed through common piping up to the front of the mixer and automatically fed into multiple mixers by means of a switching valve.

No worries even if the mixer is in a remote location.

"Received on the 1st floor of the plant -> Pneumatic conveyance -> To the mixer on the 2nd floor

Received at the receiving room -> Pneumatic conveyance -> To the mixer in the plant"

Received at the receiving room -> Pneumatic conveyance -> To the mixer in the plant"

Various equipment can be installed in the line to prevent dust scattering and foreign matter contamination.

⚫︎Dumping Server

The feed port for raw materials is high enough to reduce strain on the worker's lower back. The built-in dust collector suppresses the scattering of dust.

The feed port for raw materials is high enough to reduce strain on the worker's lower back. The built-in dust collector suppresses the scattering of dust.

⚫︎LINESIFTER®︎

It efficiently performs sieving, removal of foreign matter, and lump crushing.

It efficiently performs sieving, removal of foreign matter, and lump crushing.

⚫︎PowMagnet

Magnetic foreign matter such as metals are removed.

Magnetic foreign matter such as metals are removed.

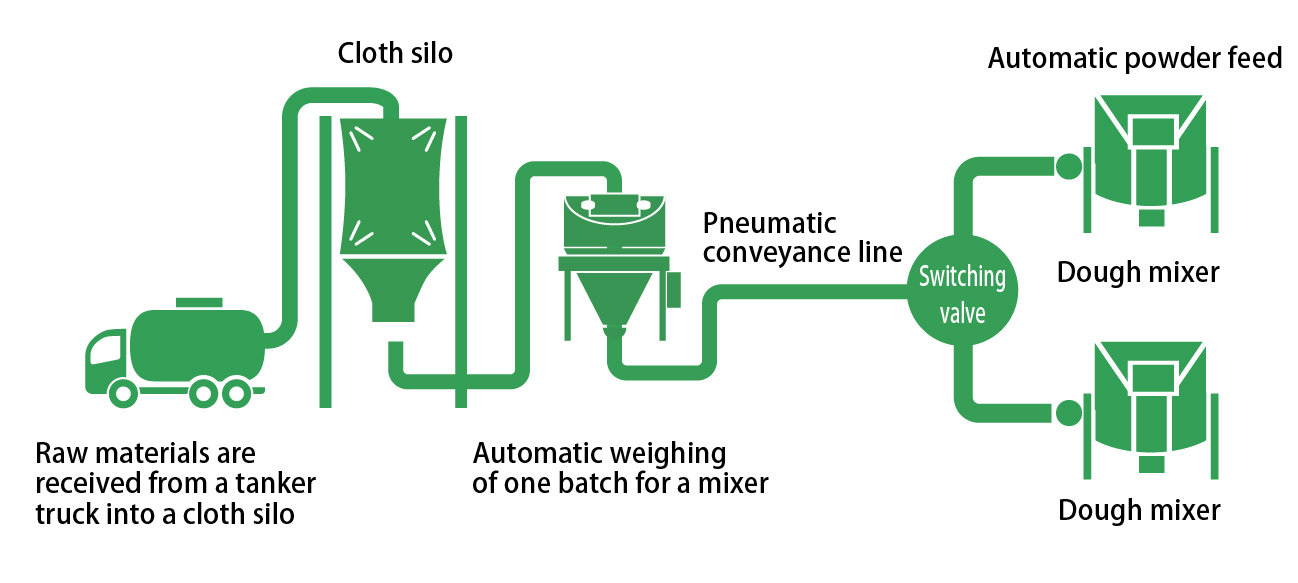

■Plan2 Accepted from a tanker truck into the "cloth silo"

Raw materials are received from the tanker truck into the indoor "cloth silo" and stored. A "PowScale (weighted weighing equipment)" or branch valve can be installed in the pneumatic conveyor piping to separately feed raw materials for only the specified weight to multiple mixers. It is also possible to remove foreign matter with "LINESIFTER®" and "PowMagnet" installed in the line.

Advantages of TSUKASA "cloth silo"

⚫︎Reducing introduction costs

Since it is made of polyester, introduction costs can be reduced compared to steel-plate silos.

⚫︎Easy installation in existing plants

It can be folded and carried in during installation work, and can be installed in an existing plant in a short period of time. There is no need to remove the ceiling or walls.

⚫︎Excellent durability and breathability

It is easy to control the temperature, etc., and it is expected to be used continuously for more than 10 years depending on the usage situation.

⚫︎Accepting a wide range of storage volumes

We can accommodate a variety of storage volumes, not to mention the volume for one general tanker truck, so please contact us for consultation.

Since it is made of polyester, introduction costs can be reduced compared to steel-plate silos.

⚫︎Easy installation in existing plants

It can be folded and carried in during installation work, and can be installed in an existing plant in a short period of time. There is no need to remove the ceiling or walls.

⚫︎Excellent durability and breathability

It is easy to control the temperature, etc., and it is expected to be used continuously for more than 10 years depending on the usage situation.

⚫︎Accepting a wide range of storage volumes

We can accommodate a variety of storage volumes, not to mention the volume for one general tanker truck, so please contact us for consultation.