Case Studies

Case Examples

Screw Feeder Tilt Adjustable With Handle

Handling Process

Type of Industry

Beverage manufacturer

Introduced Products

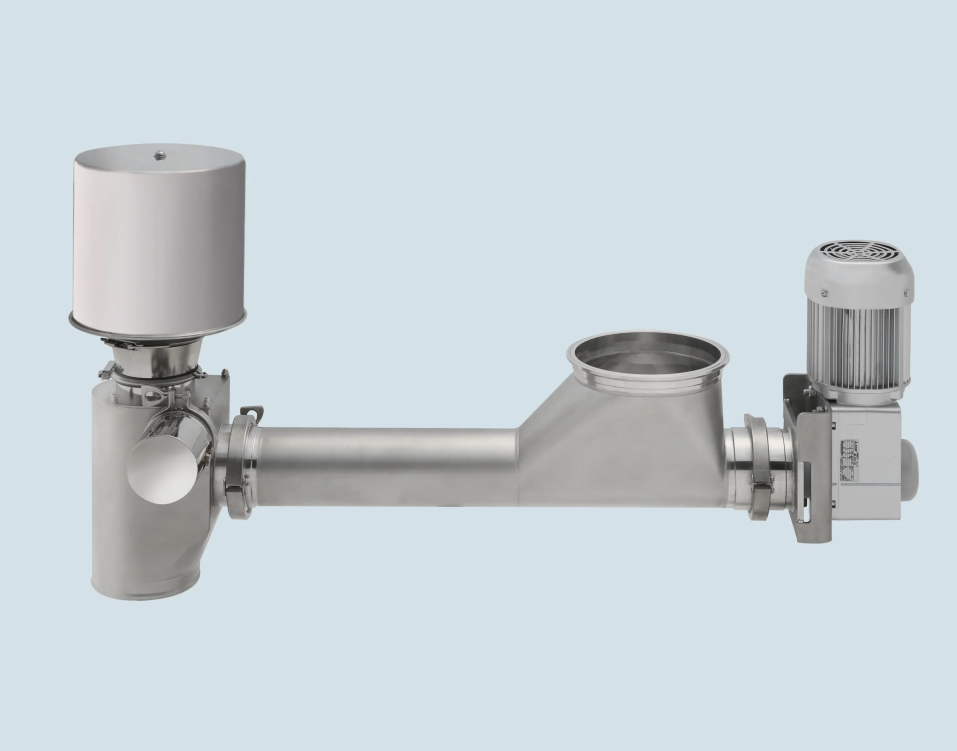

Inclined screw feeder (can be washed with water)

Customer requests

A supply line that can convey grains without them being damaged, and is easy to clean

We want to lift granules to a height at a beverage plant, drop them from there, and supply them to a weighing machine. Therefore, we are researching a method where the shape of granules are not damaged and can be efficiently transported. In addition, consideration should be given to operation in limited plant space and ease of cleaning when changing lots. We received such a request from one of our customers.

TSUKASA's response: part1

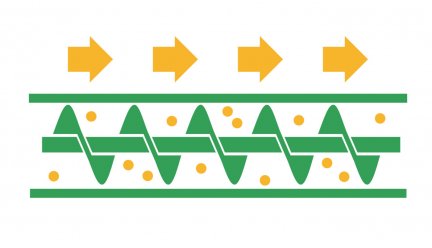

Proposal of a "mechanical type" to protect the granule shape

In order to avoid damage to the shape of granules, a "mechanical type" in which a screw rotates in a pipe for conveyance was considered. As a specific product, we proposed the inclined screw feeder.

↓

【What was the effect】

⚫︎We were able to achieve "easy conveyance"

Large pressure and friction on granules during transport, and collisions in piping can be avoided, ensuring that the shape of the granules is maintained, and easy conveyance to the feed port of the weighing machine has been achieved.

↓

【What was the effect】

⚫︎We were able to achieve "easy conveyance"

Large pressure and friction on granules during transport, and collisions in piping can be avoided, ensuring that the shape of the granules is maintained, and easy conveyance to the feed port of the weighing machine has been achieved.

TSUKASA's response: part2

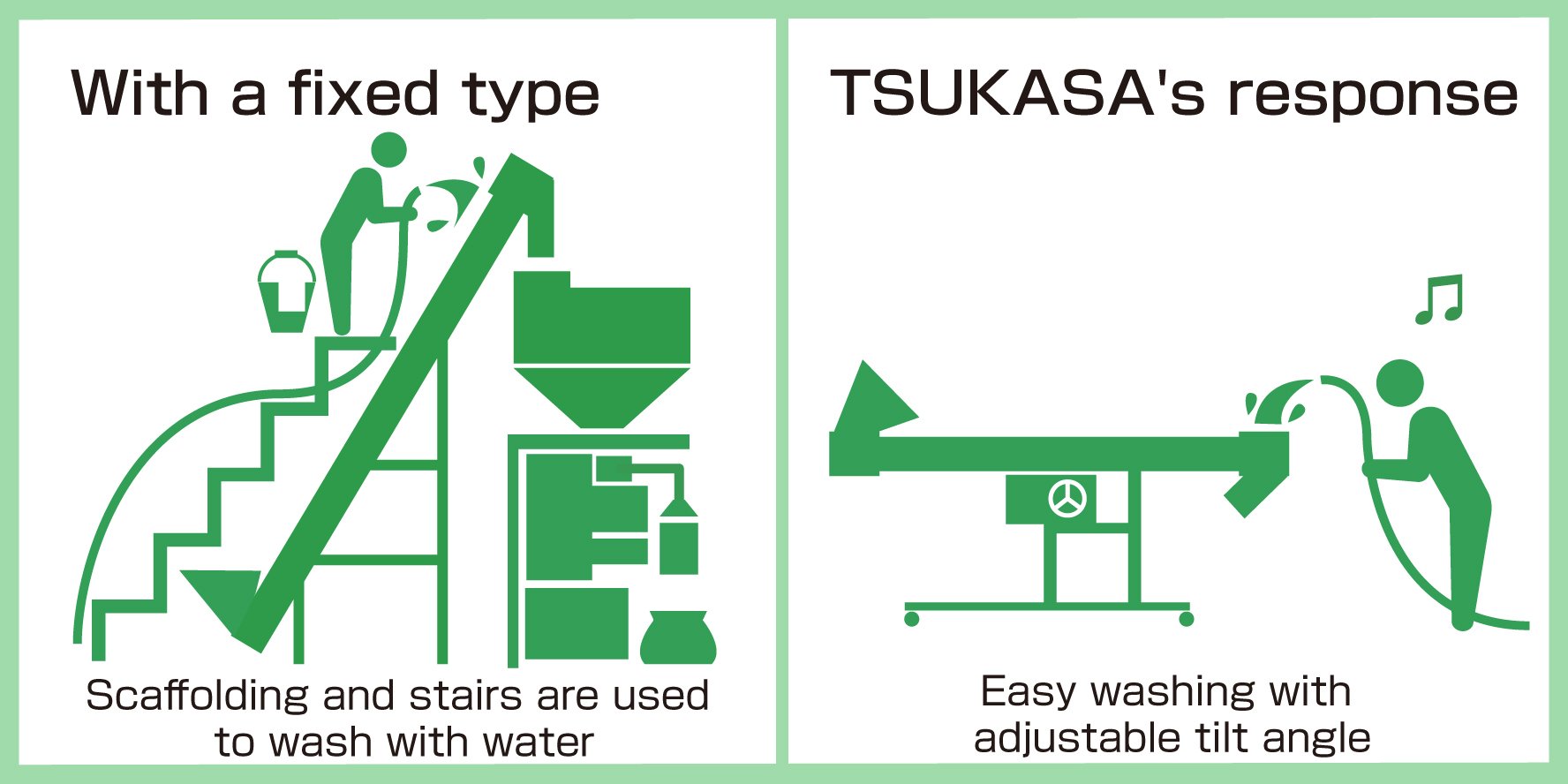

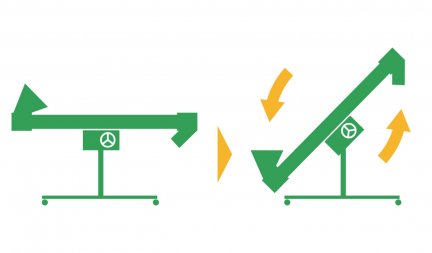

Tilt angle can be adjusted by handle operation

We have developed a structure that enables a fixed tilt angle (horizontal or 45 degrees in this case) to be adjusted by a gear-type handle operation. This is achieved by setting the fulcrum point in the middle of the feeder.

⚫︎Height adjustment for easy cleaning

While moving like a seesaw, you can reach every corner to clean the equipment. This includes movements like "lowering the equipment to an accessible position" or "raising the lower part to waist height", etc. You no longer have to go up a stage or stairs like a fixed feeder to carry out work.

⚫︎Easy to move to the washing room

When the feeder is level, it can be moved to another location smoothly. You can move the equipment to the washing room without worrying about the height of the ceiling of the aisle or the size of the entrances and exits.

⚫︎Less of a burden of having to reassemble

It is also possible to dry and reassemble parts after washing them with water without having to work in an uncomfortable posture—you can adjust the angle and height to those that are easy to work with.

⚫︎Safety and security performance has also been further improved

The angle of inclination is adjusted by handle operation, so there is no need to worry about shaking, wobbling, or imbalance, which is similar to manual and intuitive adjustments.

While moving like a seesaw, you can reach every corner to clean the equipment. This includes movements like "lowering the equipment to an accessible position" or "raising the lower part to waist height", etc. You no longer have to go up a stage or stairs like a fixed feeder to carry out work.

⚫︎Easy to move to the washing room

When the feeder is level, it can be moved to another location smoothly. You can move the equipment to the washing room without worrying about the height of the ceiling of the aisle or the size of the entrances and exits.

⚫︎Less of a burden of having to reassemble

It is also possible to dry and reassemble parts after washing them with water without having to work in an uncomfortable posture—you can adjust the angle and height to those that are easy to work with.

⚫︎Safety and security performance has also been further improved

The angle of inclination is adjusted by handle operation, so there is no need to worry about shaking, wobbling, or imbalance, which is similar to manual and intuitive adjustments.

Designed according to customer needs

TSUKASA's tilted screw feeder can be designed in a variety of ways according to the type of powder and granules handled by the customer—"from where, at what location, and under what conditions do you want to convey materials?" and "what equipment do you want to connect?” Please feel free to contact us.