Case Studies

Case Examples

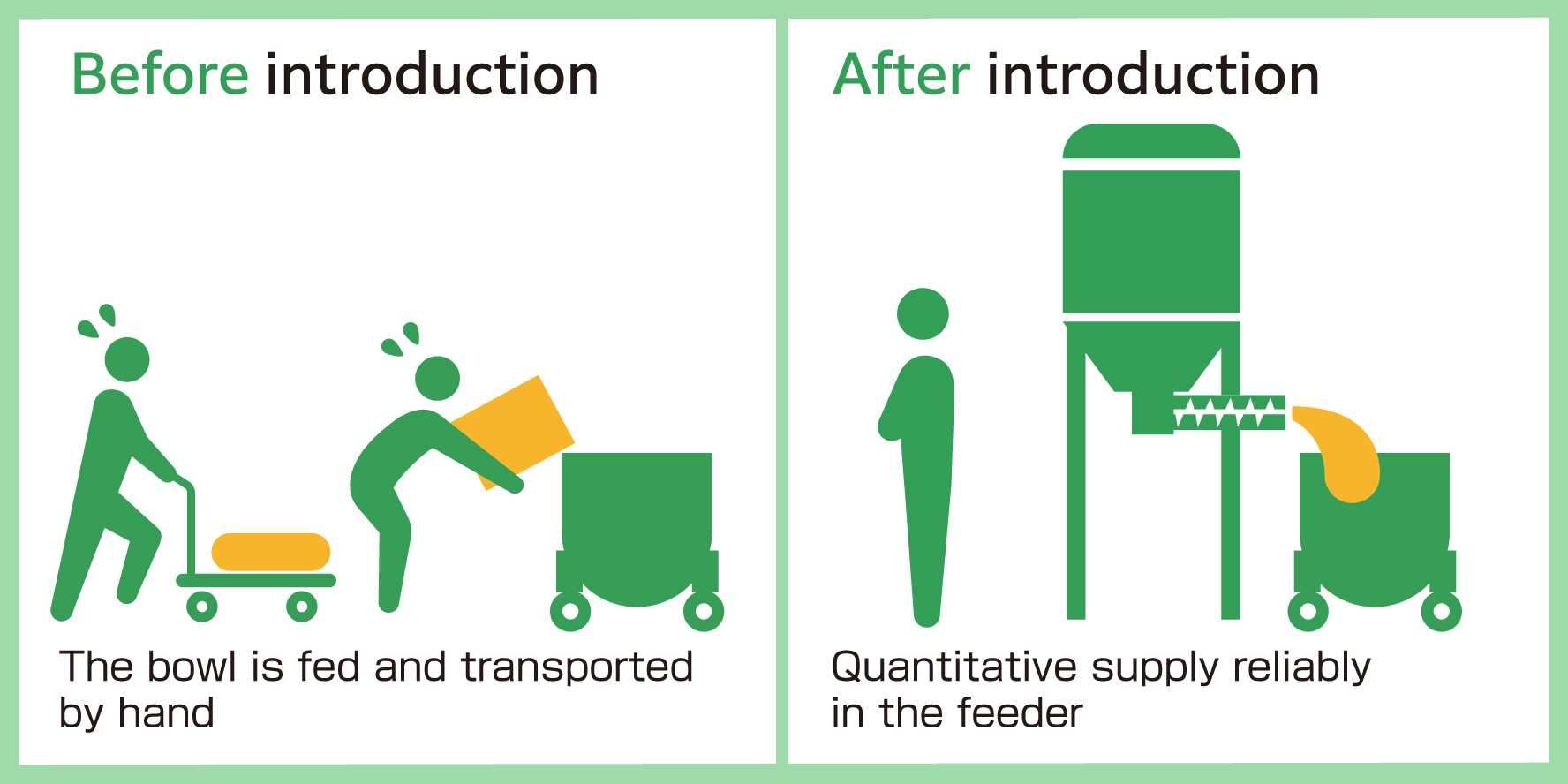

Automatic feeding of powders to movable bowls for bread spiral mixers

Material Receiving and Powder Feeding Process

Type of Industry

Bread making company

Introduced Products

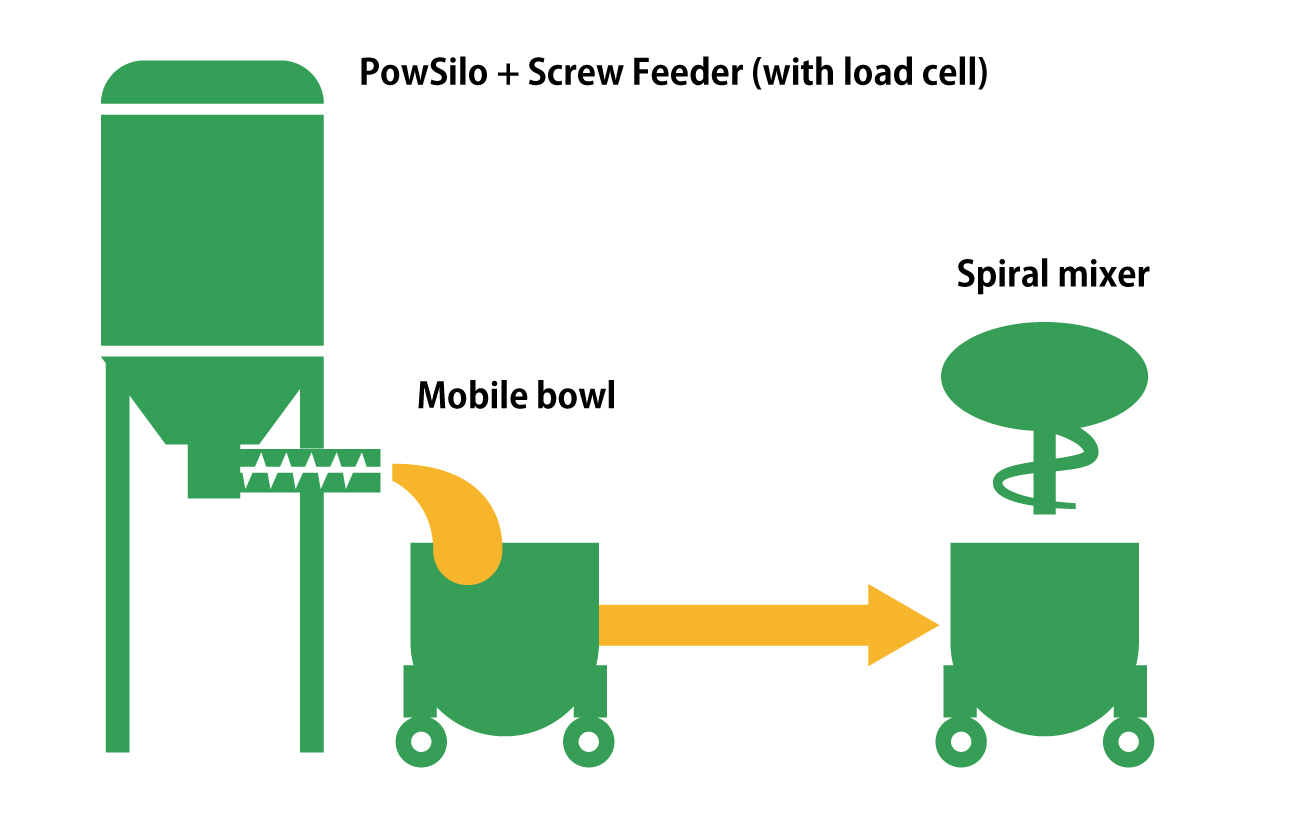

PowSilo + Screw Feeder (with scale)

Customer requests

We want to eliminate the burden of manual bowl feeding and transportation

The customer mainly made hard bread such as French bread, and was using a spiral mixer with a moving bowl. When the bowls of flour and other powdered raw materials were added, they were weighed in small batches by hand in the weighing room, and then placed on a trolley to a distant mixer. So they asked TSUKASA, "This is a lot of work to do, can we do something about it?"

Suggestions from TSUKASA

Automatic quantitative supply to the bowl from the PowSilo (with scale)

We suggested automatic weighing of powder raw materials by batch stocked in a "PowSilo" and quantitative feed of bowls with a screw feeder.

Workflow

Stock powder raw materials in a PowSilo

↓

Set the supply volume, etc. from the operator panel

↓

Powder weight is detected by the load cell and discharged by the screw feeder

↓

Place the bowl of raw materials into the mixer

↓

Set the supply volume, etc. from the operator panel

↓

Powder weight is detected by the load cell and discharged by the screw feeder

↓

Place the bowl of raw materials into the mixer

What is the "loss-in-weight method (continuous weight loss control method)" suggested this time?

Feedback control is based on the weight discharged from the screw feeder.

When the target weighing weight is approached, the rotation speed of the screw feeder is reduced to improve weighing accuracy.

When the target weighing weight is approached, the rotation speed of the screw feeder is reduced to improve weighing accuracy.

Results of introduction

Shorten the distance to carry the bowl

Just place a bowl near the spiral mixer to receive the powder material, set it as it is and it is ready to be put into the dough mixer. The trouble of rolling the trolley from the weighing room was eliminated.

No need to install a weighing machine in the previous process

There is no need to install a stand alone weighing machine in advance. The number of equipment in the entire line has been reduced, contributing to space saving in the factory and reducing installation costs.

Reduced risk of contamination

The risk of contamination due to manual weighing and long-distance transportation has been greatly reduced. By pneumatic conveyance, it is possible to supply powder raw materials to the PowSilo, and foreign matter can be removed by the LINESIFTER and magnet.