Weighing Process

Precisely weight large amount of main materials and small amount of additives

Precisely weight large amount of main materials and small amount of additives

Weighing equipment

Divider Scale Mobile Robot

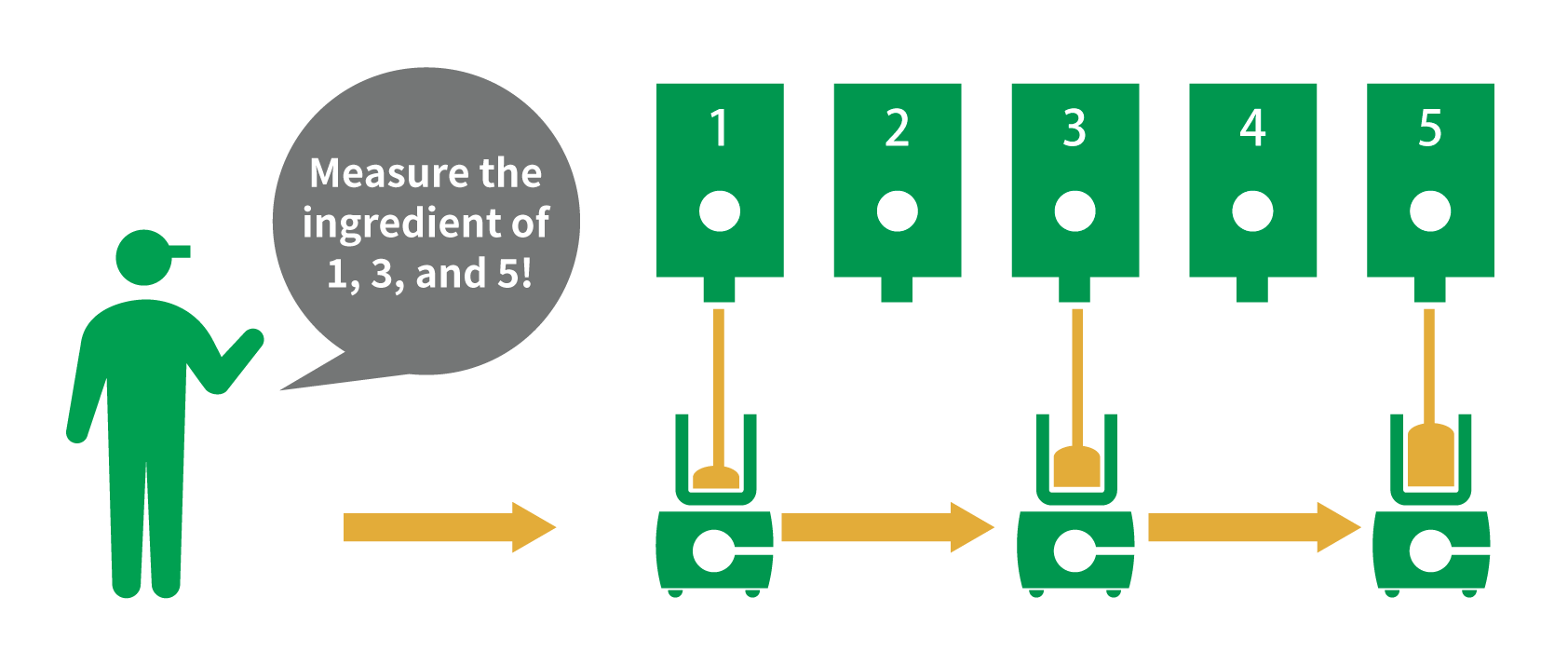

Integrating a weighing function into the AMR enables full automation from weighing to transport

Features

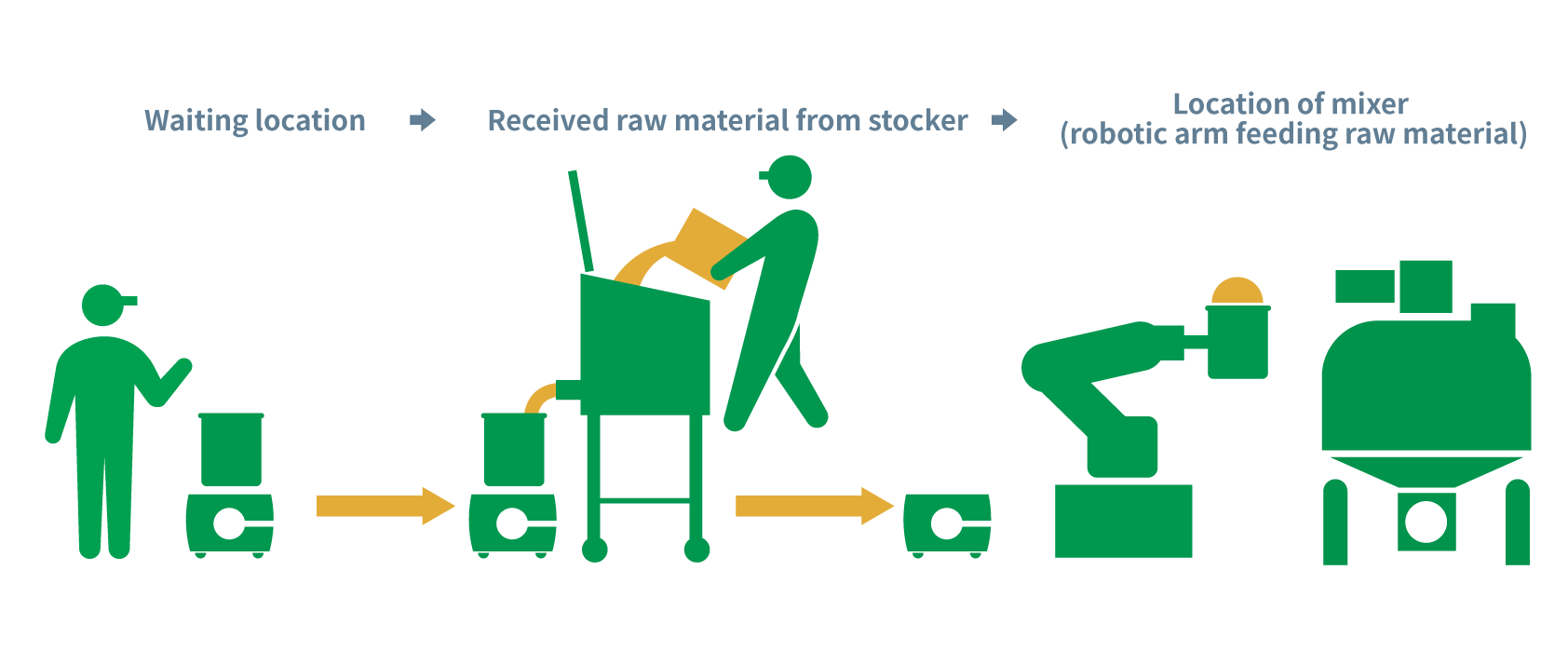

⚫︎An AMR (autonomous mobile robot) receives raw materials from each stocker, automatically weighs them, and conveys them to the designated location, achieving automation and labor saving.

⚫︎The adoption of AMR ensures a safe collaborative environment between humans and machines.

⚫︎Containers can be flexibly transported within the AMR’s operating range. Significantly improves factory space utilization compared to conveyor-based transport.

⚫︎Our in-house Sler framework enables one-stop design, development, and verification.

⚫︎The adoption of AMR ensures a safe collaborative environment between humans and machines.

⚫︎Containers can be flexibly transported within the AMR’s operating range. Significantly improves factory space utilization compared to conveyor-based transport.

⚫︎Our in-house Sler framework enables one-stop design, development, and verification.

Options

⚫︎An articulated robot can feed weighed raw materials from the AMR directly into the next process equipment (e.g., mixing).