Material Receiving and Powder Feeding Process

Achieved Speedy and efficient reception and supply of materials

Achieved Speedy and efficient reception and supply of materials

Automatic bag opening System

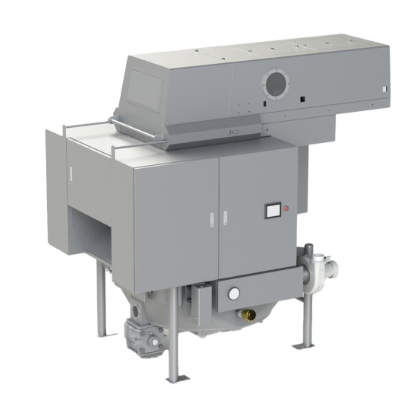

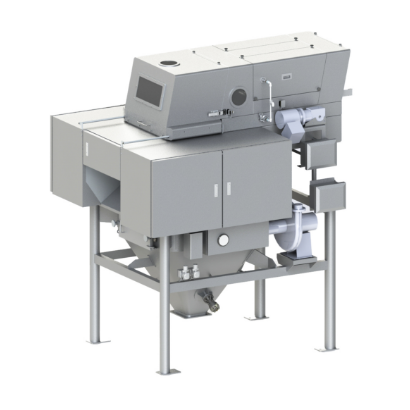

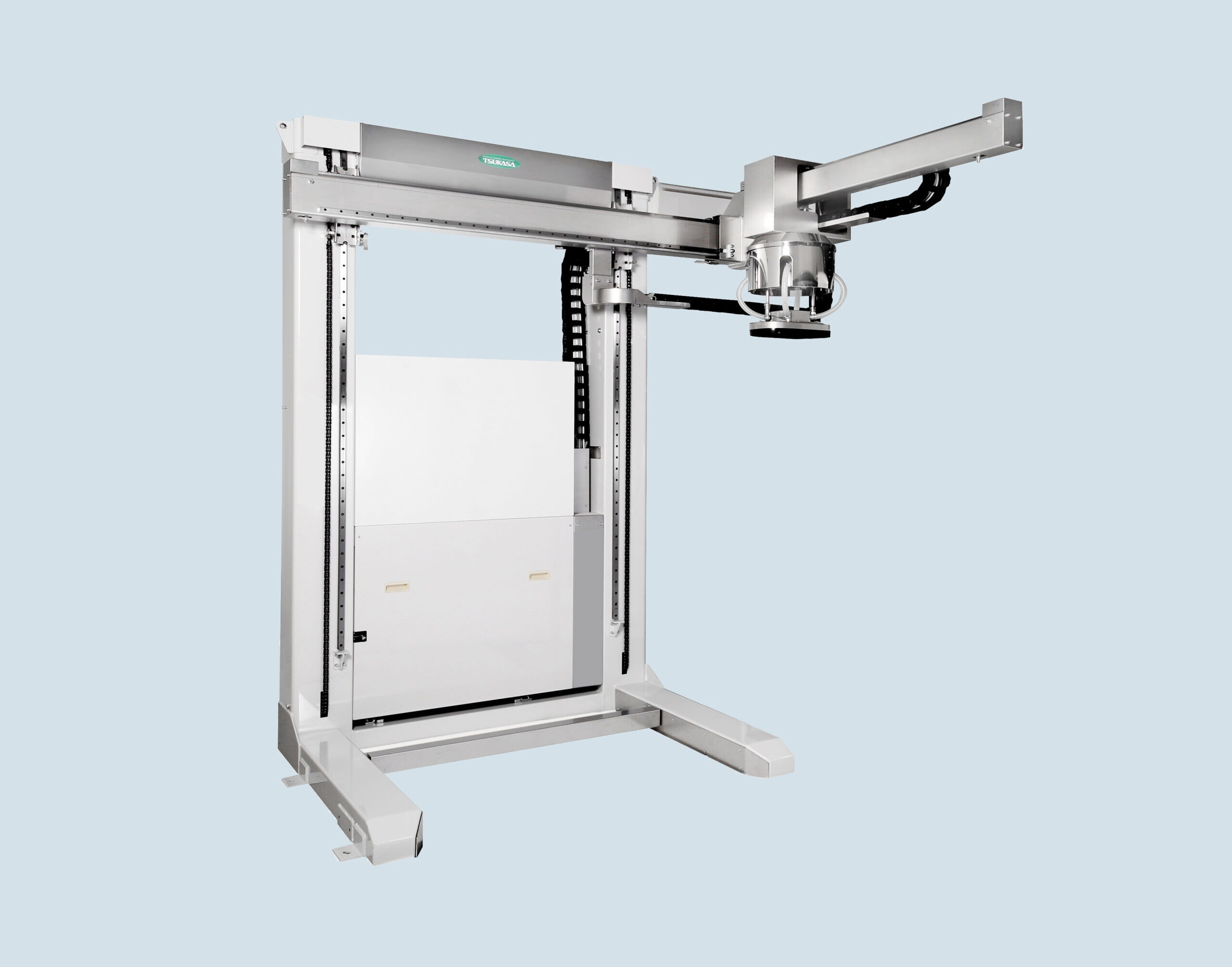

PowOpener(PO)

Compact automatic bag-opening equipment you can place anywhere

Features

⚫︎Processes up to 200 bags/hour with a 99.9% raw material recovery rate, thanks to a specialized opening mechanism. (Performance may vary depending on raw material type, bag shape, and required capacity.)

⚫︎Compatible with paper bags, double-layered paper bags (with inner plastic liners), and plastic bags.

⚫︎Handles bag weights up to 30 kg.

⚫︎Easy empty bag handling by a patented auto-folding discharge system.

⚫︎An internal structure is also very simple and cleaning and a maintenance are very easy for it.

⚫︎Washable design available.

⚫︎The PowOpener offers two lower hopper types: a low-height table feeder and a high-discharge hopper optimized for smooth raw material flow.

⚫︎Compatible with paper bags, double-layered paper bags (with inner plastic liners), and plastic bags.

⚫︎Handles bag weights up to 30 kg.

⚫︎Easy empty bag handling by a patented auto-folding discharge system.

⚫︎An internal structure is also very simple and cleaning and a maintenance are very easy for it.

⚫︎Washable design available.

⚫︎The PowOpener offers two lower hopper types: a low-height table feeder and a high-discharge hopper optimized for smooth raw material flow.

Basic Operation

1.INLET

Bags with powder material are supplied automatically by belt conveyor.

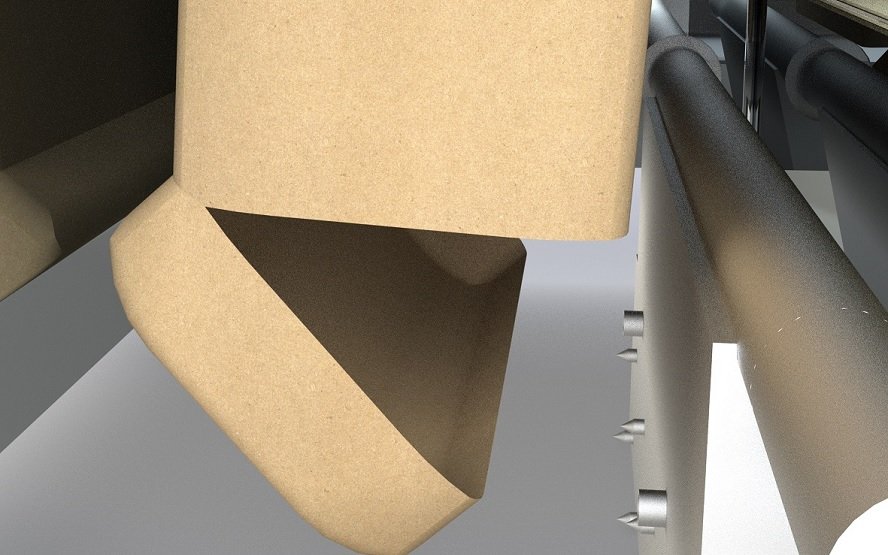

2.OPEN BAG

Fixed bag is slit by special cutter.

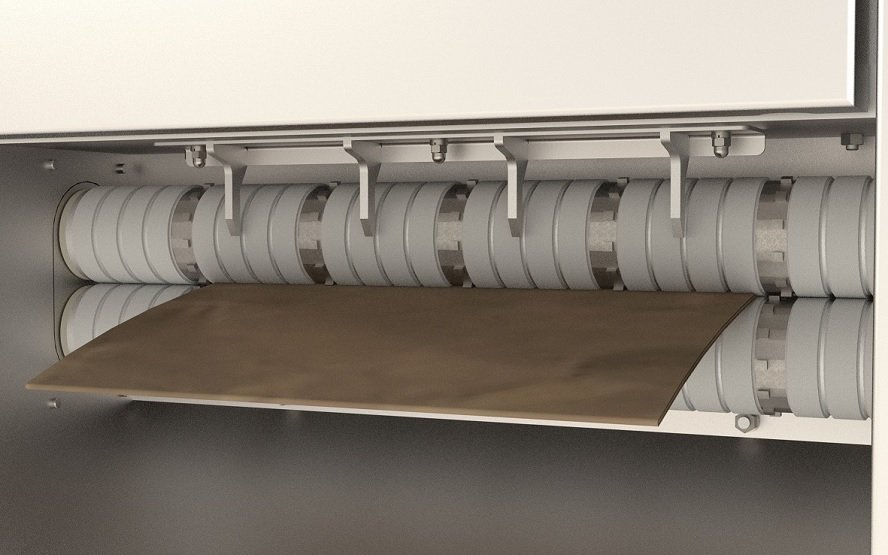

3.DISCHARGE

Powder material is discharged completely by compressed air.

4.EMPTY BAG DISCHARGING

Empty bag is discharged automatically.

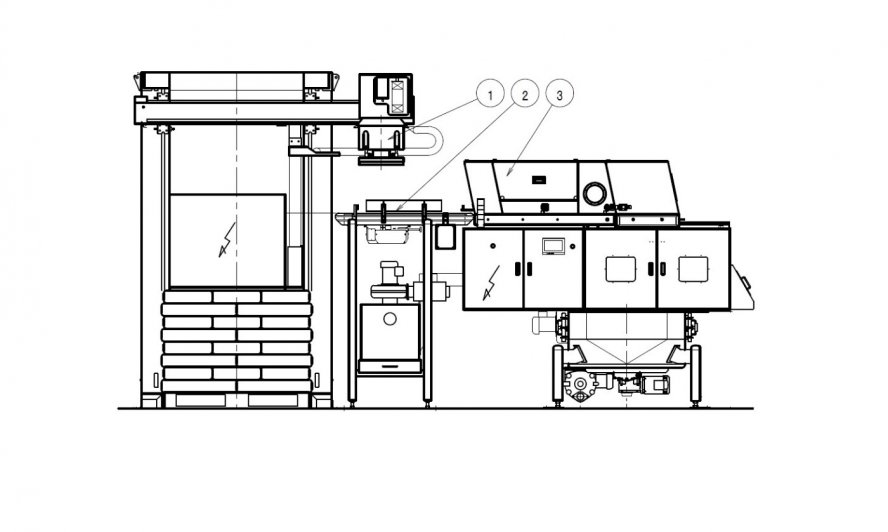

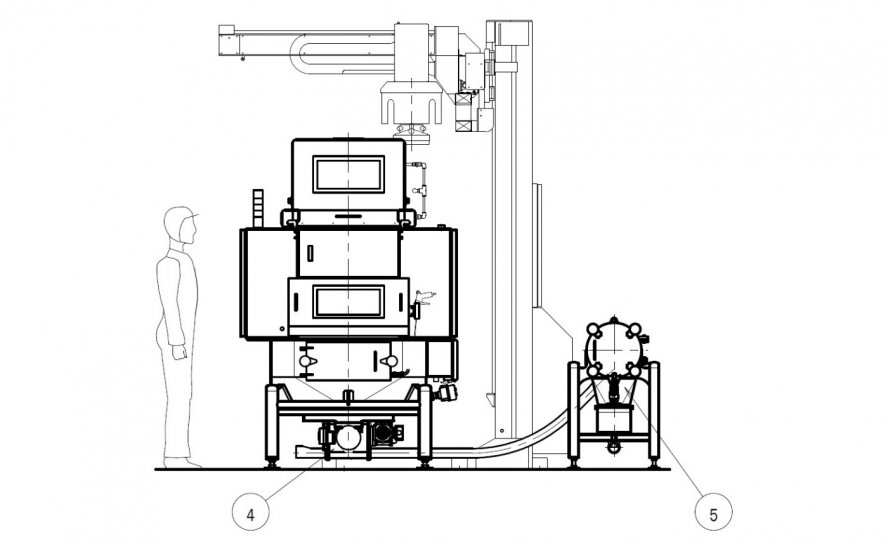

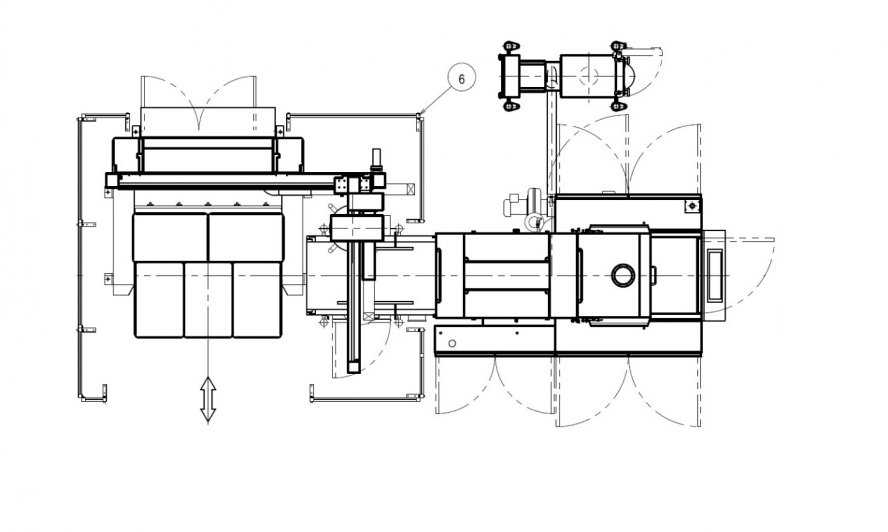

The example of installation

1.Depalletizer Robo

2.Receiving conveyor (With dust collector)

3.PowOpener

4.PowRotor Light-weight

5.LINESIFTER

6.Guard fence

2.Receiving conveyor (With dust collector)

3.PowOpener

4.PowRotor Light-weight

5.LINESIFTER

6.Guard fence

Options

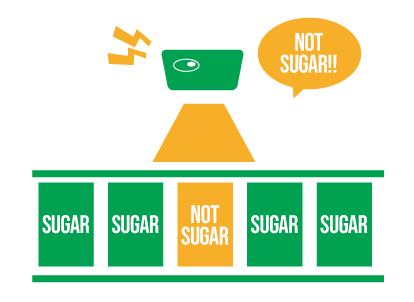

PowOpener(with PV checker)

Image recognition of the design on the surface of the raw material bag prevents accidental feeding.

Special specifications

large bag specification

⚫︎Accommodates larger bag sizes of raw materials with light specific gravity

Explosion-proof specification

⚫︎Specifications that do not allow electronic components or in-equipment wiring to be the source of ignition