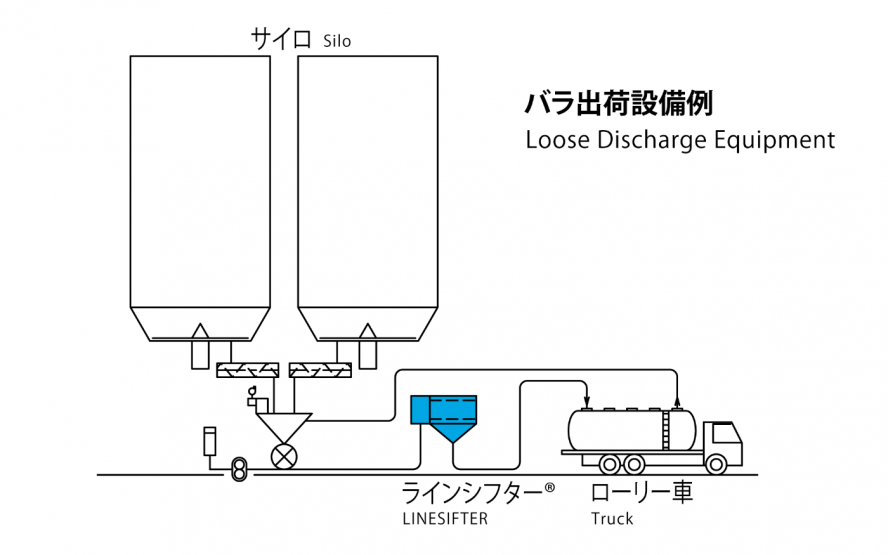

Material Receiving and Powder Feeding Process

Achieved Speedy and efficient reception and supply of materials

Achieved Speedy and efficient reception and supply of materials

Automatic bag opening System

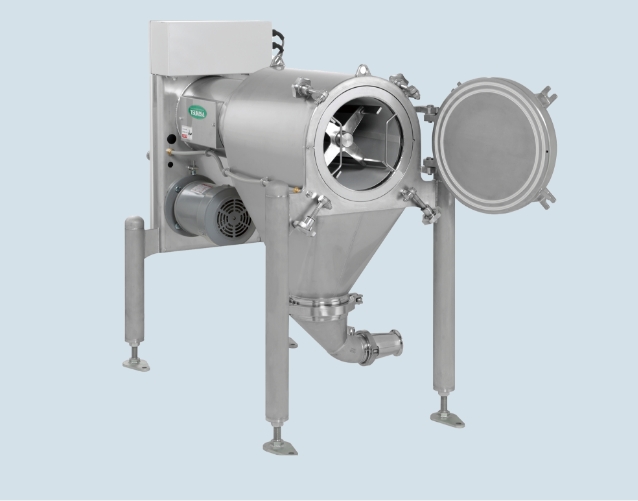

LINESIFTER® Standard Model(LS)

In-line model sifter installed in the pneumatic conveyance line

Features

⚫︎Foreign material removal and crushing clumps are possible only by installing LINESIFTER into a pneumatic transportation line.

⚫︎Beater blade rotating inside the cylindrical sieve disperses powder toward the entire circumference of sieve, realizing highly efficient sifting.

⚫︎Only the granular material which passed the sieve is pneumatically transported.

⚫︎Check of a sieve and exchange are very easy.

⚫︎The super-low-pitched sound design with very little vibration.

⚫︎Slight pressure loss.

⚫︎It is correspondence for water washing.(option)

⚫︎Beater blade rotating inside the cylindrical sieve disperses powder toward the entire circumference of sieve, realizing highly efficient sifting.

⚫︎Only the granular material which passed the sieve is pneumatically transported.

⚫︎Check of a sieve and exchange are very easy.

⚫︎The super-low-pitched sound design with very little vibration.

⚫︎Slight pressure loss.

⚫︎It is correspondence for water washing.(option)

Specifications

⚫︎Powder-contacting areas:Stainless steel

⚫︎Sieve: selection of polyethylene terephthalate (PET), magnetic stainless steel mesh, or punched stainless steel

⚫︎Other parts : Stainless steel and steel

⚫︎Options:Tornado beater, Foreign-material receiving pot, PowClean System

⚫︎Sieve: selection of polyethylene terephthalate (PET), magnetic stainless steel mesh, or punched stainless steel

⚫︎Other parts : Stainless steel and steel

⚫︎Options:Tornado beater, Foreign-material receiving pot, PowClean System

Capacity Chart

⚫︎In the case of extra-strength flour (apparent specific gravity of 0.5) and a mesh size of 0.6 mm.

⚫︎Capacity may vary according to usage conditions

⚫︎Capacity may vary according to usage conditions