Case Studies

Material Receiving and Powder Feeding Process

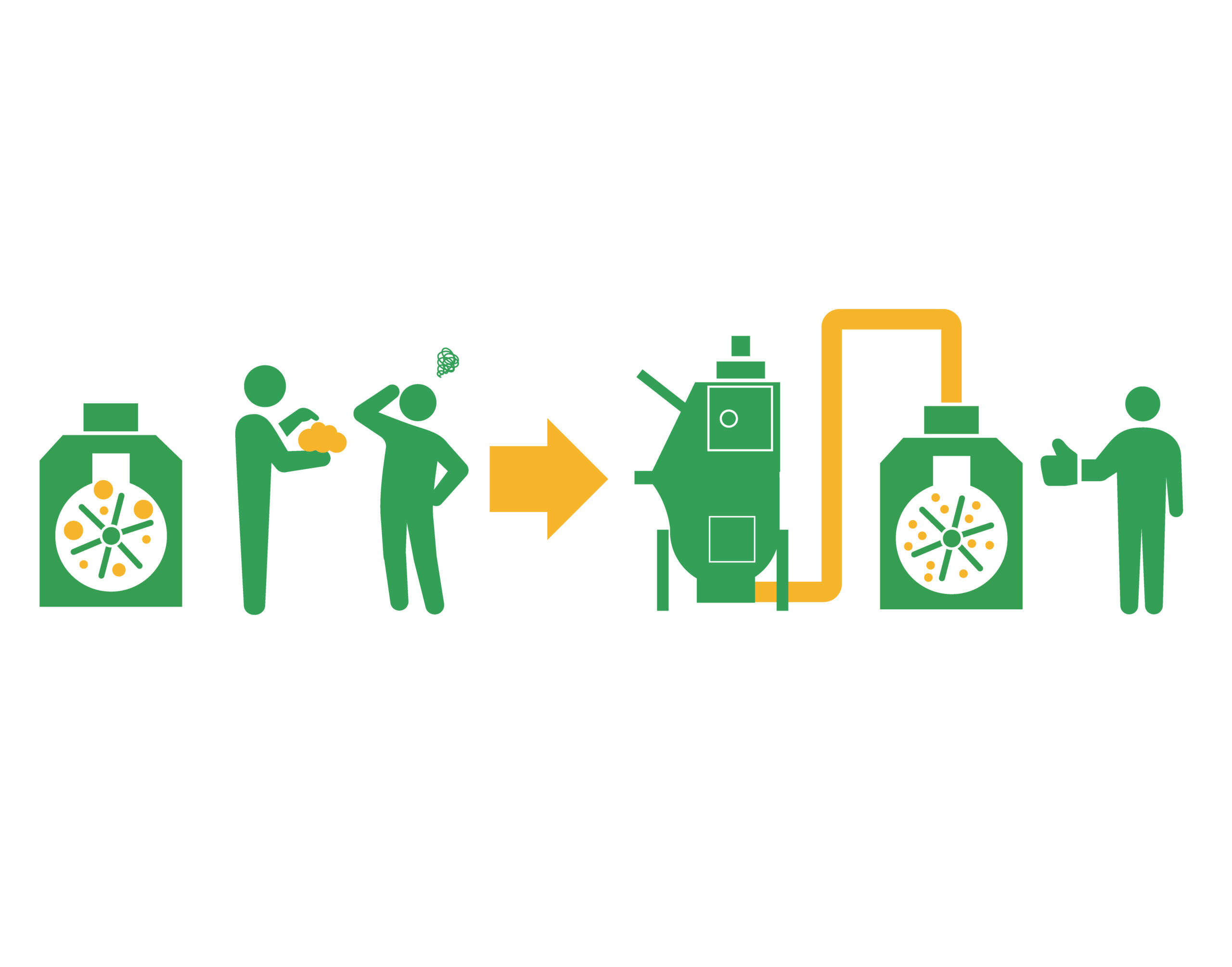

Automatically crushes powders that have solidified or coagulated inside the paper bag

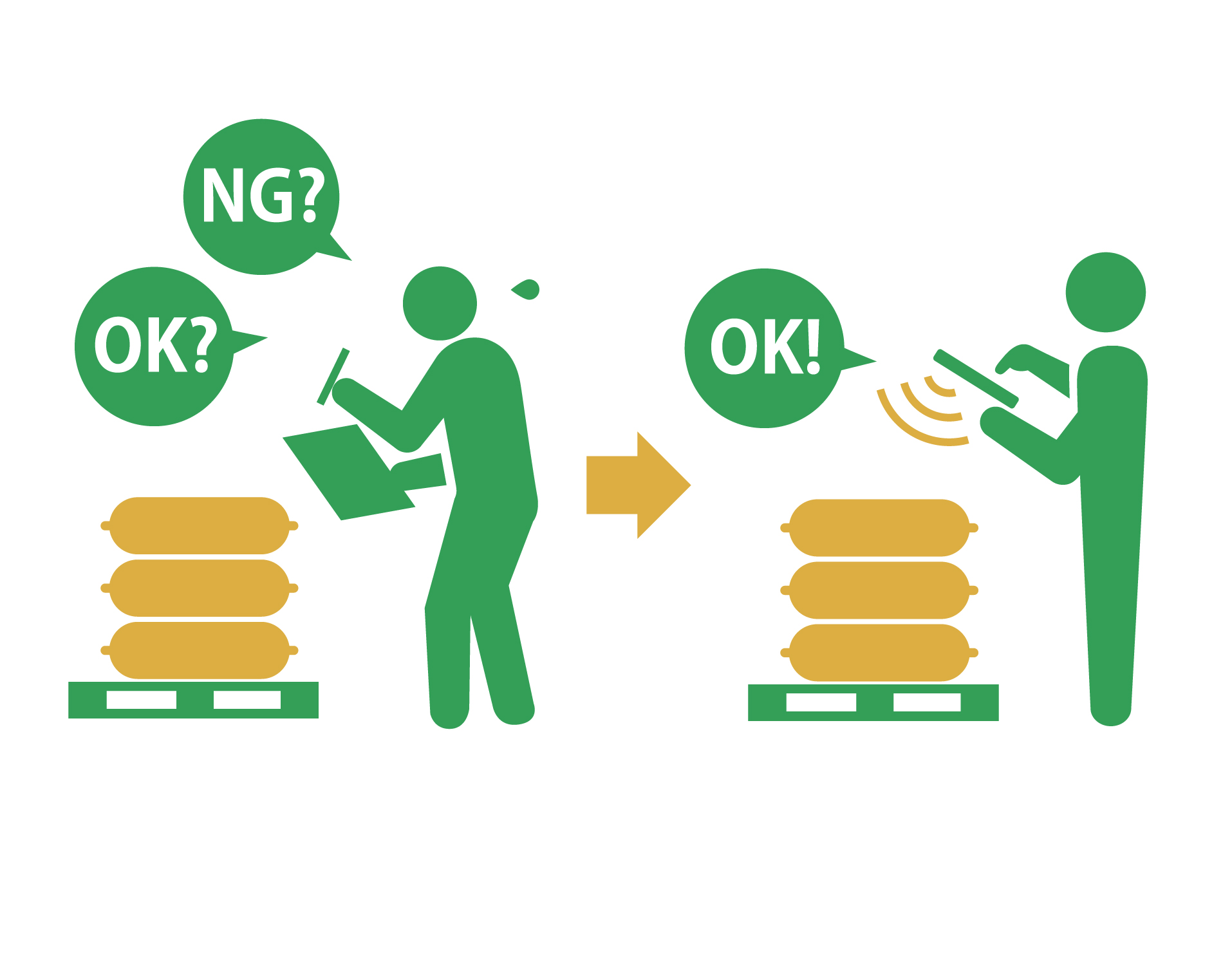

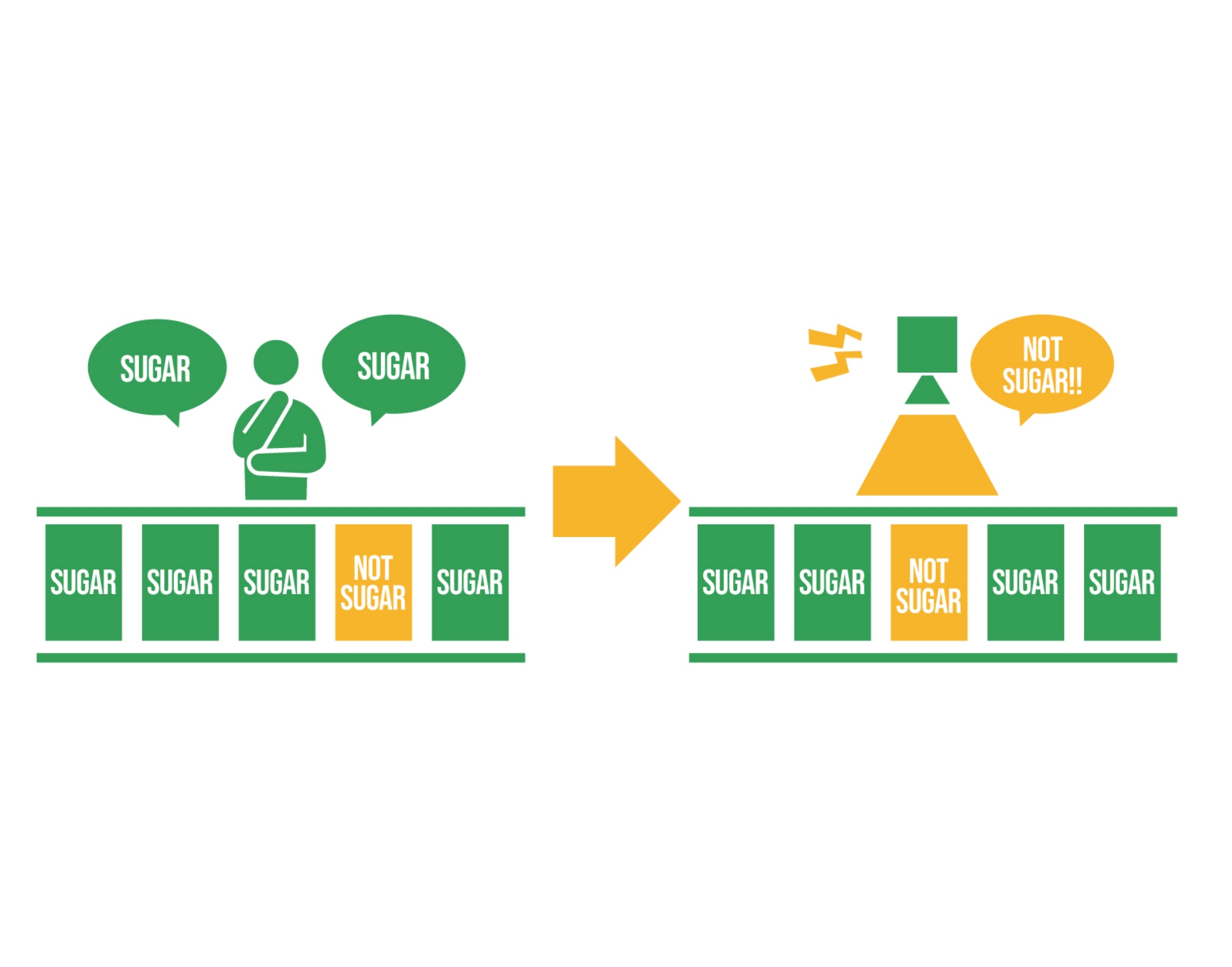

Using a tablet to prevent incorrect raw material charging

Upon receipt, flour is immediately sieved and pneumatically conveyed to the mixer.

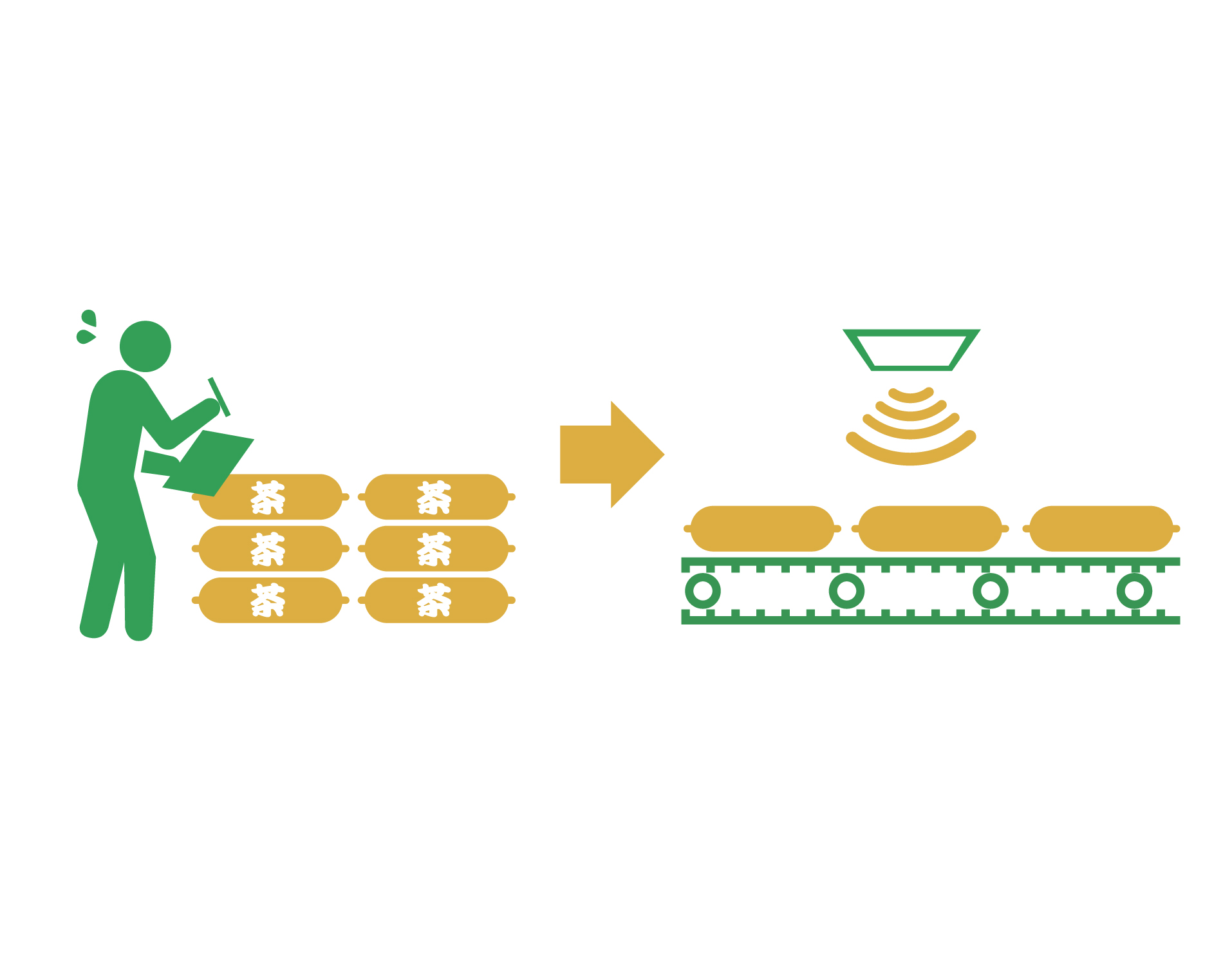

Labor-saving traceability of tea beverages using OCR

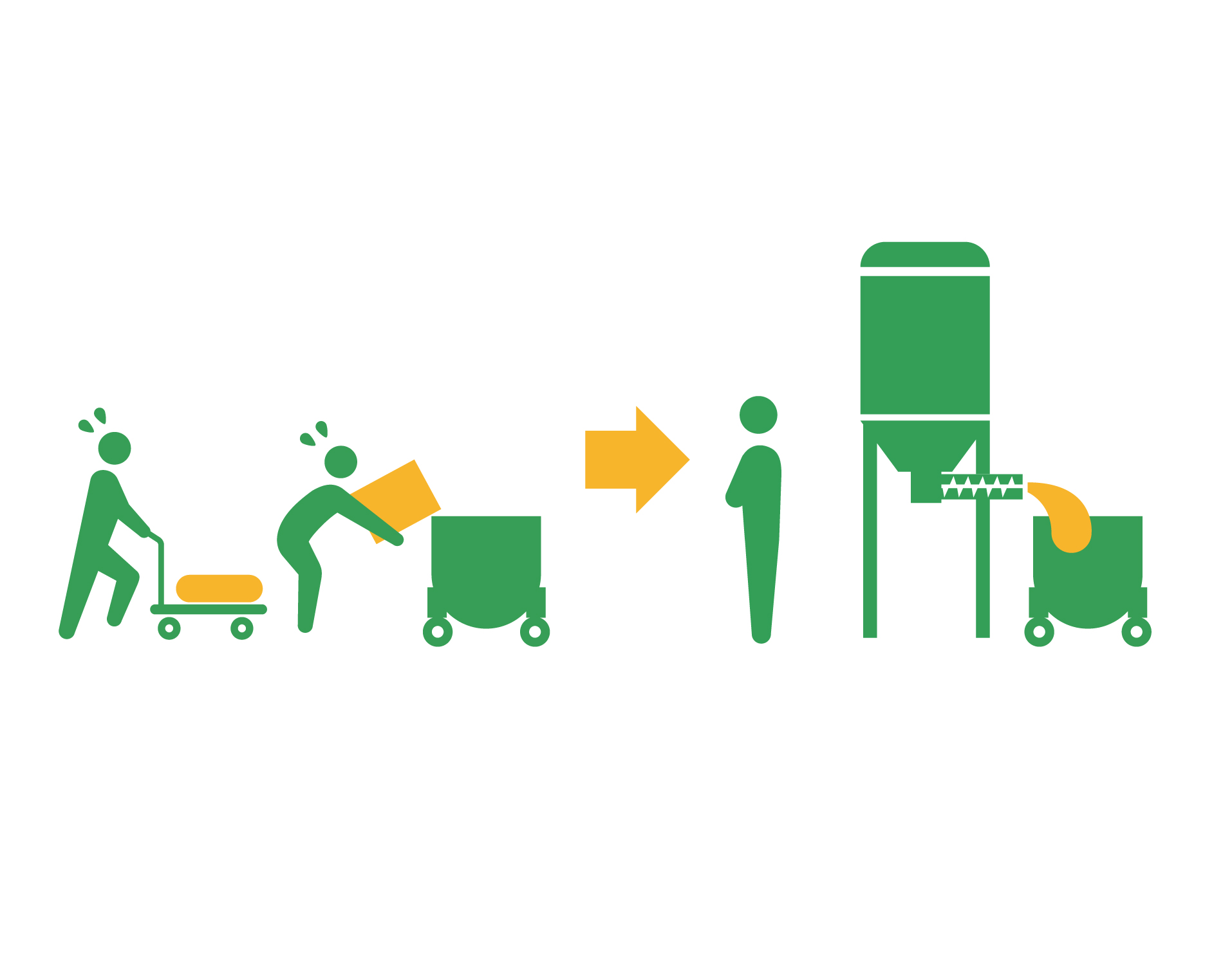

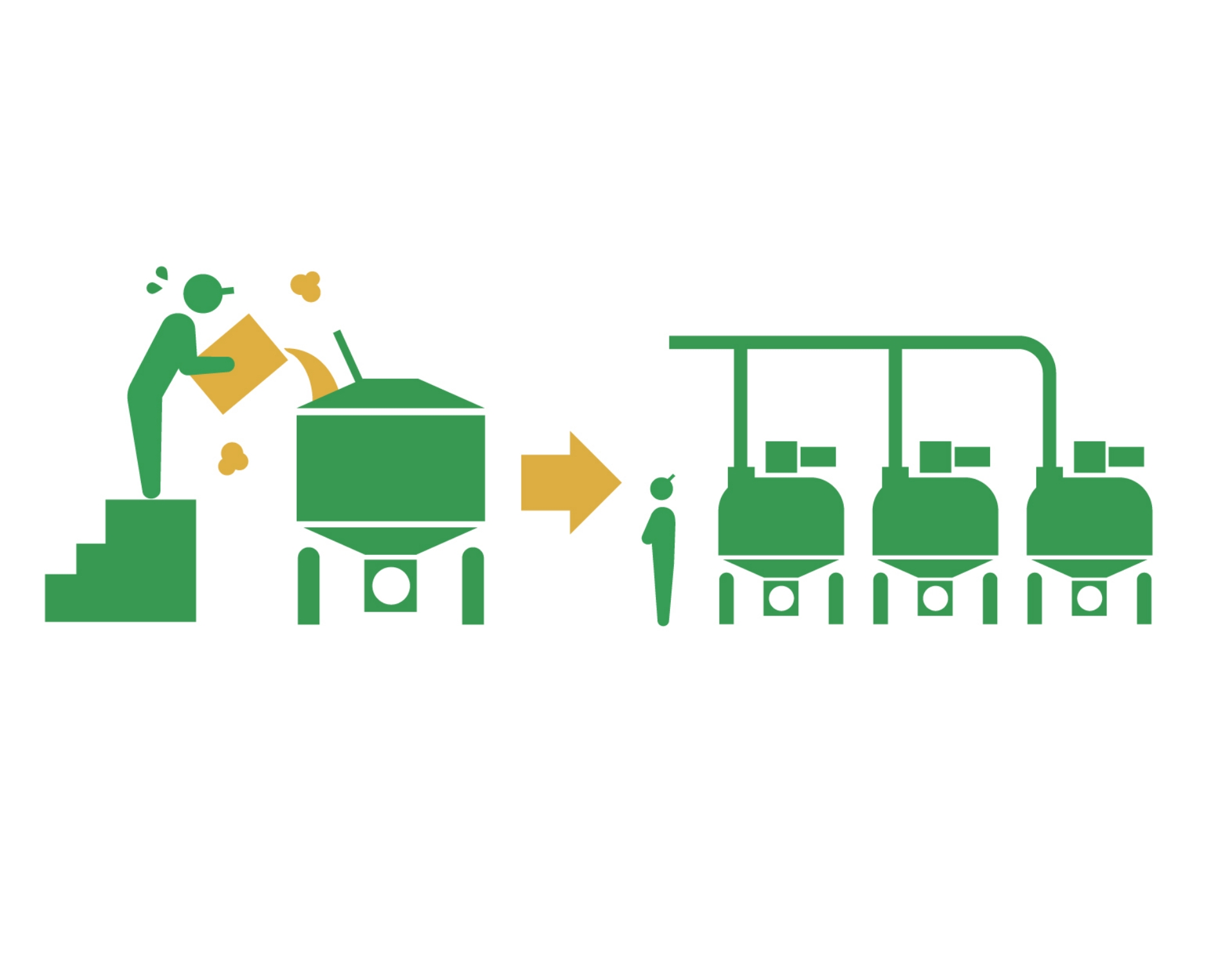

Automate the feeding of powders such as skim milk powder to the dissolving tank

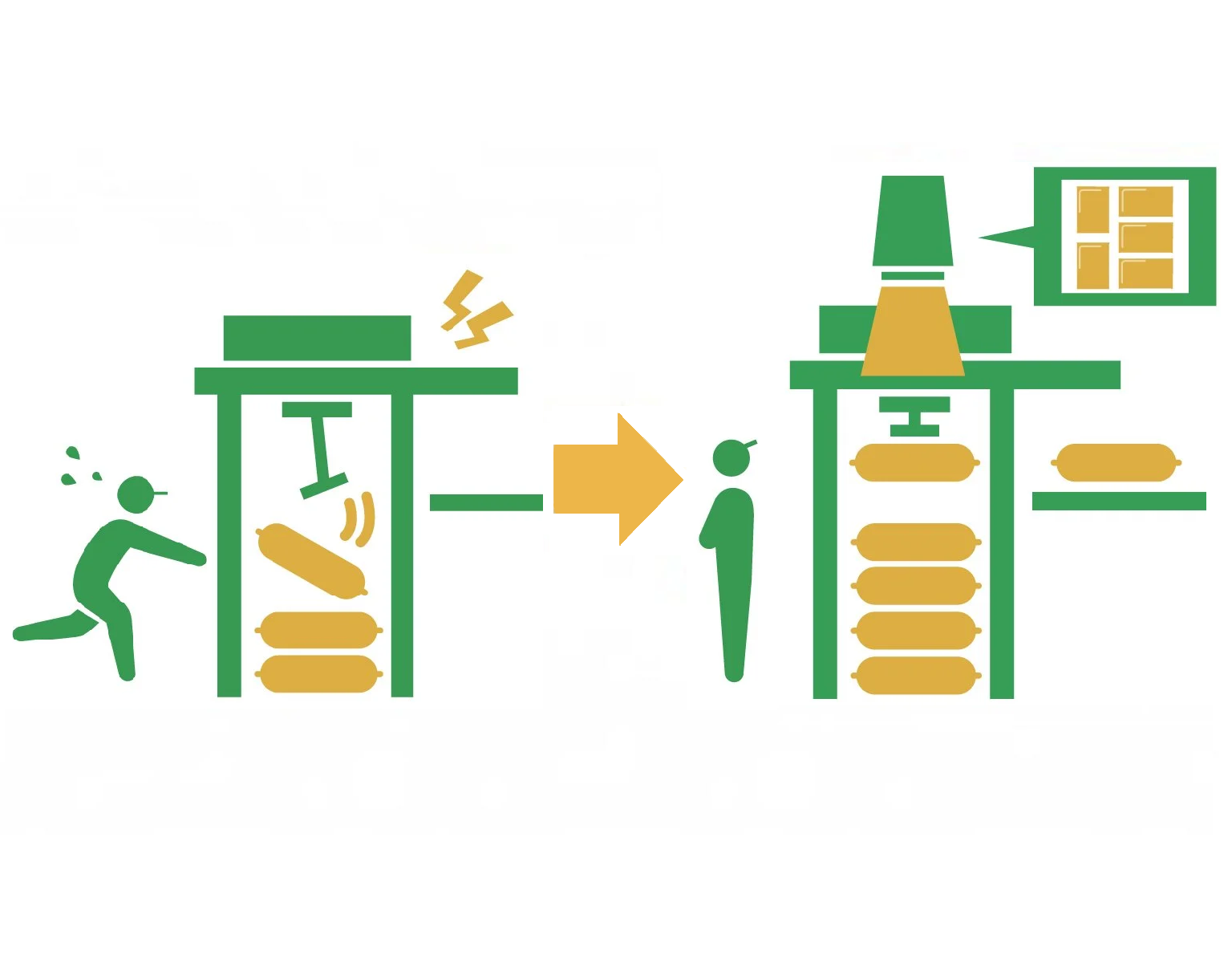

Stabilizes continuous automatic powder feeding at noodle factories

Automatic feeding of powders to movable bowls for bread spiral mixers

The mixing time in the noodle dough mixer is greatly reduced

Improved direct feeding of raw materials into the dough mixer

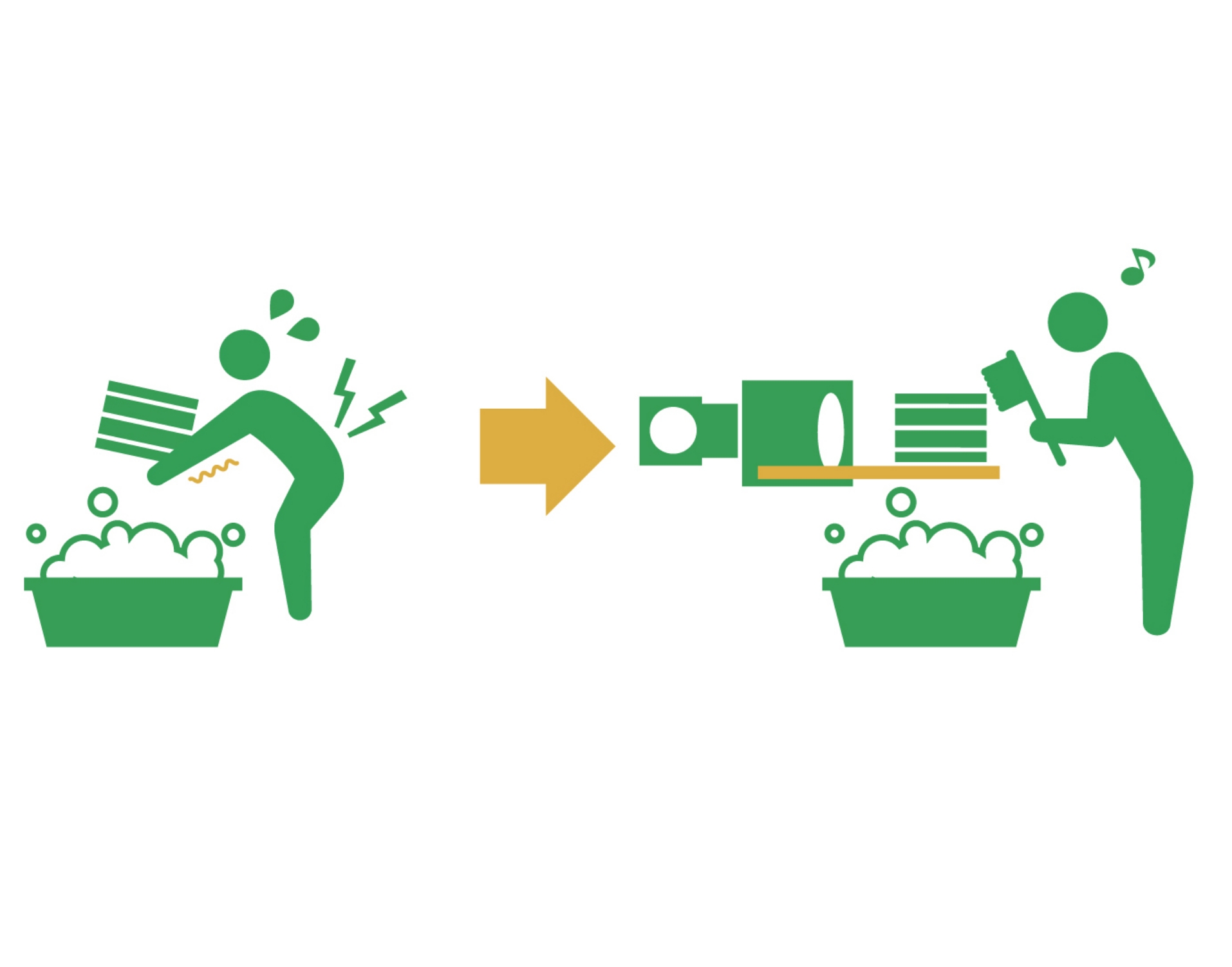

Two models have been developed to simplify rotor washing

Aiming for zero defect rate by supplying bags to bag-opening equipment

Image recognition shuts out erroneous feeding of powder raw materials