Case Studies

Case Examples

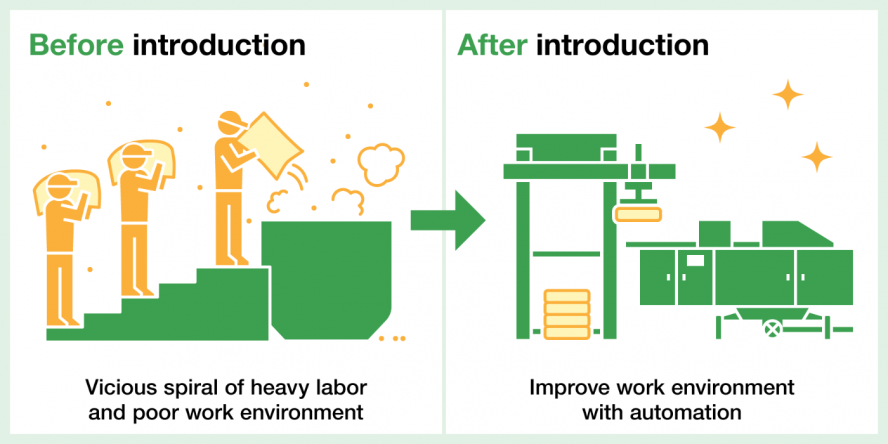

Labor-saving and streamlining with our hygienic automatic bag-opening system

Material Receiving and Powder Feeding Process

Type of Industry

Beverage manufacturer

Introduced Products

Automatic bag opening system

Background and problem

We would like to eliminate heavy labor where multiple workers lift up powder materials to a feeding port at a high place.

A beverage manufacturer was feeding a large amount of powder directly to processing equipment for every batch.

It was extremely heavy labor where several workers lifted up dozens of bags, and they were worried about the burden on worker's lower back and health problems due to the fine particles when feeding it in.

The equipment's feeding port was at a high place, and it was troublesome to lift up materials with a pallet, etc., so they contacted us for improvements.

It was extremely heavy labor where several workers lifted up dozens of bags, and they were worried about the burden on worker's lower back and health problems due to the fine particles when feeding it in.

The equipment's feeding port was at a high place, and it was troublesome to lift up materials with a pallet, etc., so they contacted us for improvements.

Results of introduction

Automatic bag opening system that does not need human hands

We proposed our automatic bag-opening system and the manufacturer installed it. Our compact automatic bag-opening system incorporates into a single unit such functions as bag feed, bag surface cleaning, bag opening, and disposal of empty bags.

They are in one unit, so it can easily prevent bacteria and foreign materials from entering from outside, and it is easy to check, inspect, and clean the inside of the unit.

They are in one unit, so it can easily prevent bacteria and foreign materials from entering from outside, and it is easy to check, inspect, and clean the inside of the unit.

Improve work environment and reduce work load

The automatic bag-opening system have built-in dust collector so it can prevent powder from scattering, and It has a structure which powder less adheres on and remains in. Workers do not have to carry and put materials directly into a feeding port anymore, and work load was reduced and work environment was improved. They were very satisfied with this.