Case Studies

Case Examples

Improved recipe security during weighing

Weighing Process

Type of Industry

Bread making company

Introduced Products

Divider Scale Control system

Customer requests

Prevention of leakage of recipe information during the weighing process

When a customer introduced the automatic weighing machine “Divider Scale,” TSUKASA discussed with the customer how to set the security level. TSUKASA received requests such as, “We have many workers on short-term contracts, so we want to make sure that recipe information cannot be taken out,” and “We fine-tune the amount of powdered raw materials depending on the weather on the day, so we want to make sure that no one other than the person in charge can enter the recipe.”

Suggestions from TSUKASA

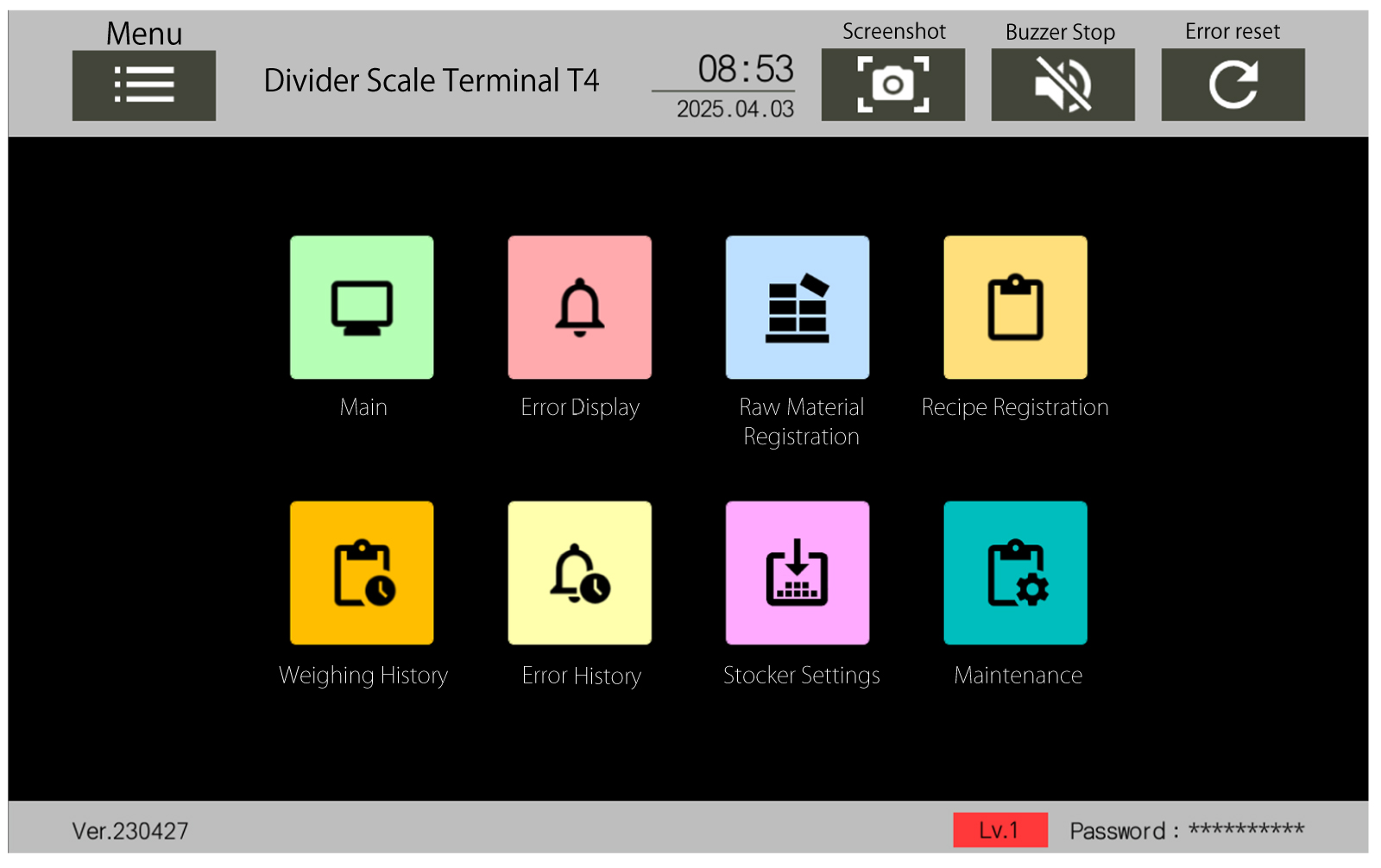

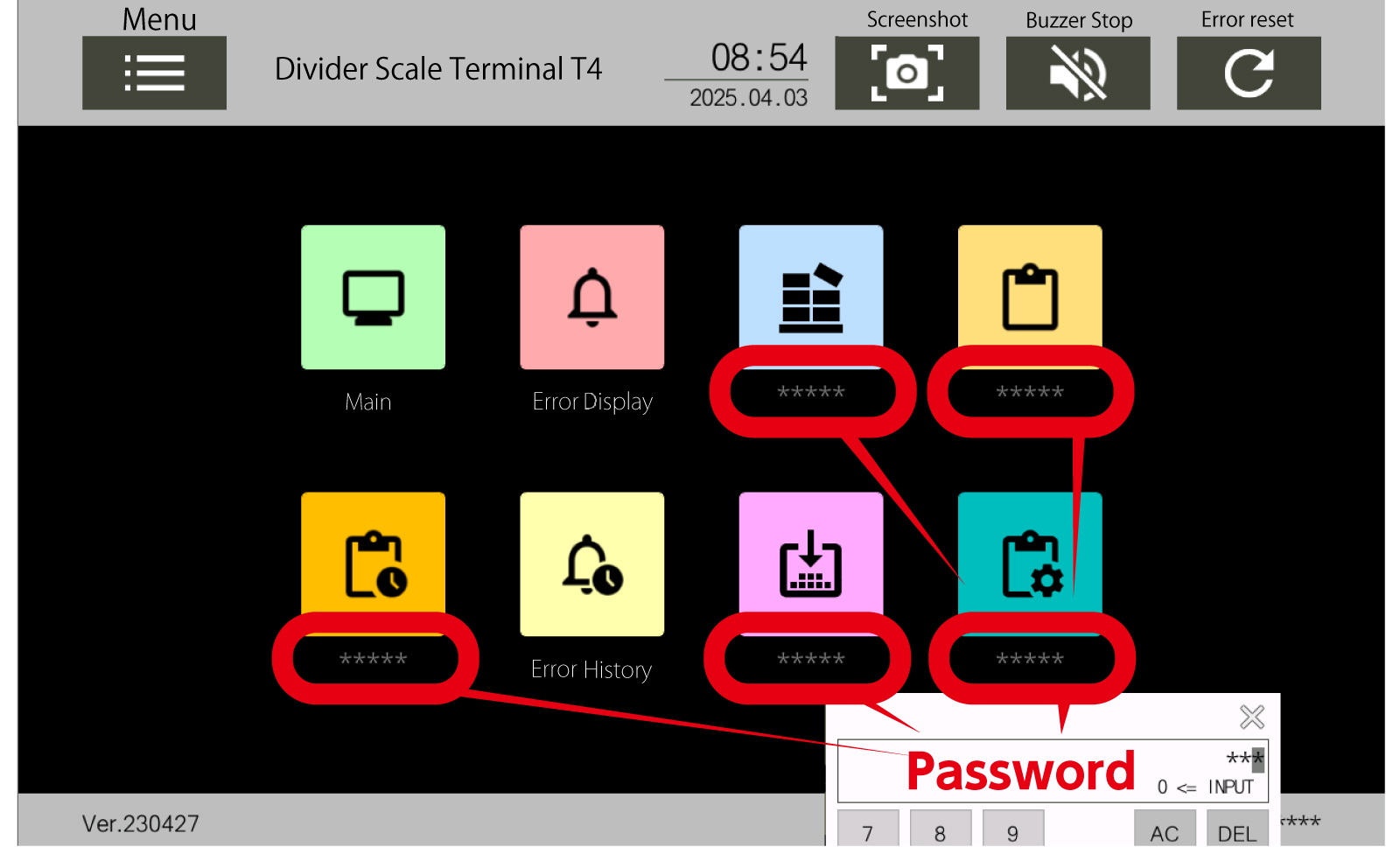

You can select the scope of password settings from three security levels

LEVEL1

Any operator can view and modify any item

LEVEL2

“Raw material Registration” and “Recipe Registration” are limited to viewing

* Modification is not possible

↓

Only the person in charge can change them after entering a password.

* Modification is not possible

↓

Only the person in charge can change them after entering a password.

LEVEL3

Viewing and modification are impossible except for “Main,” “Error Display,” and “Error History.”

↓

Only the person in charge can view and modify them after entering a password.

↓

Only the person in charge can view and modify them after entering a password.

This customer:

"Selected “LEVEL 3” to prevent recipe information leakage. They established a system in which the on-site operator only operates the unit and cannot see the types of raw materials and recipe information.

In addition, the introduction of the “Divider Scale” eliminated the need for handwritten notes and instructions, preventing the leakage of paper-based information."

In addition, the introduction of the “Divider Scale” eliminated the need for handwritten notes and instructions, preventing the leakage of paper-based information."

Additional options

The “Divider Scale Control System” also offers options to further enhance the security level. You can choose an option that best suits your production site.

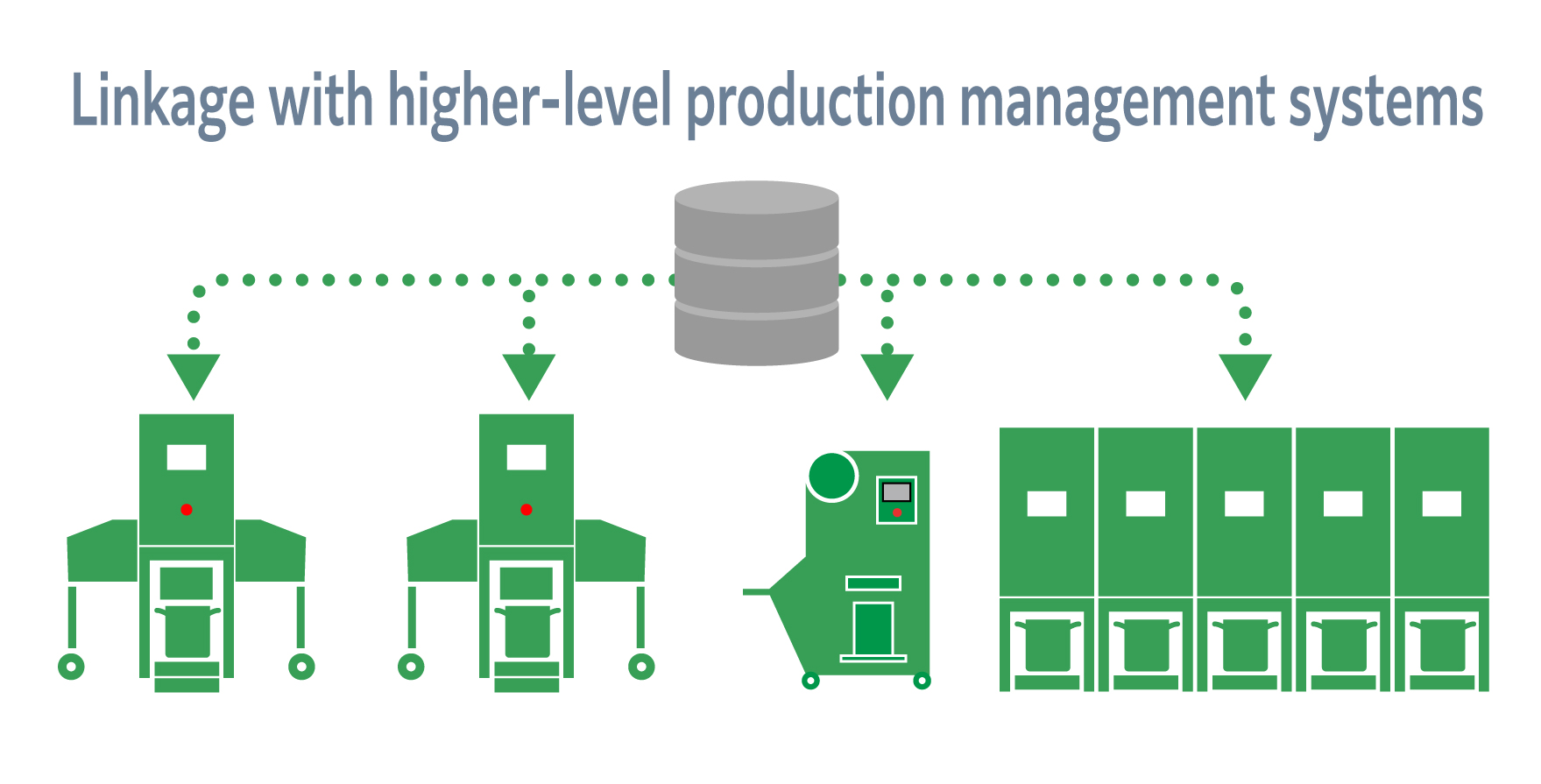

Linkage with higher-level production management systems

If your production equipment is centrally managed at the site, linkage with a higher-level production management system is also possible. For example, when weighing is performed using weighing instructions automatically received from a higher-level system, situations in which personnel are involved and see recipe information are almost entirely eliminated.

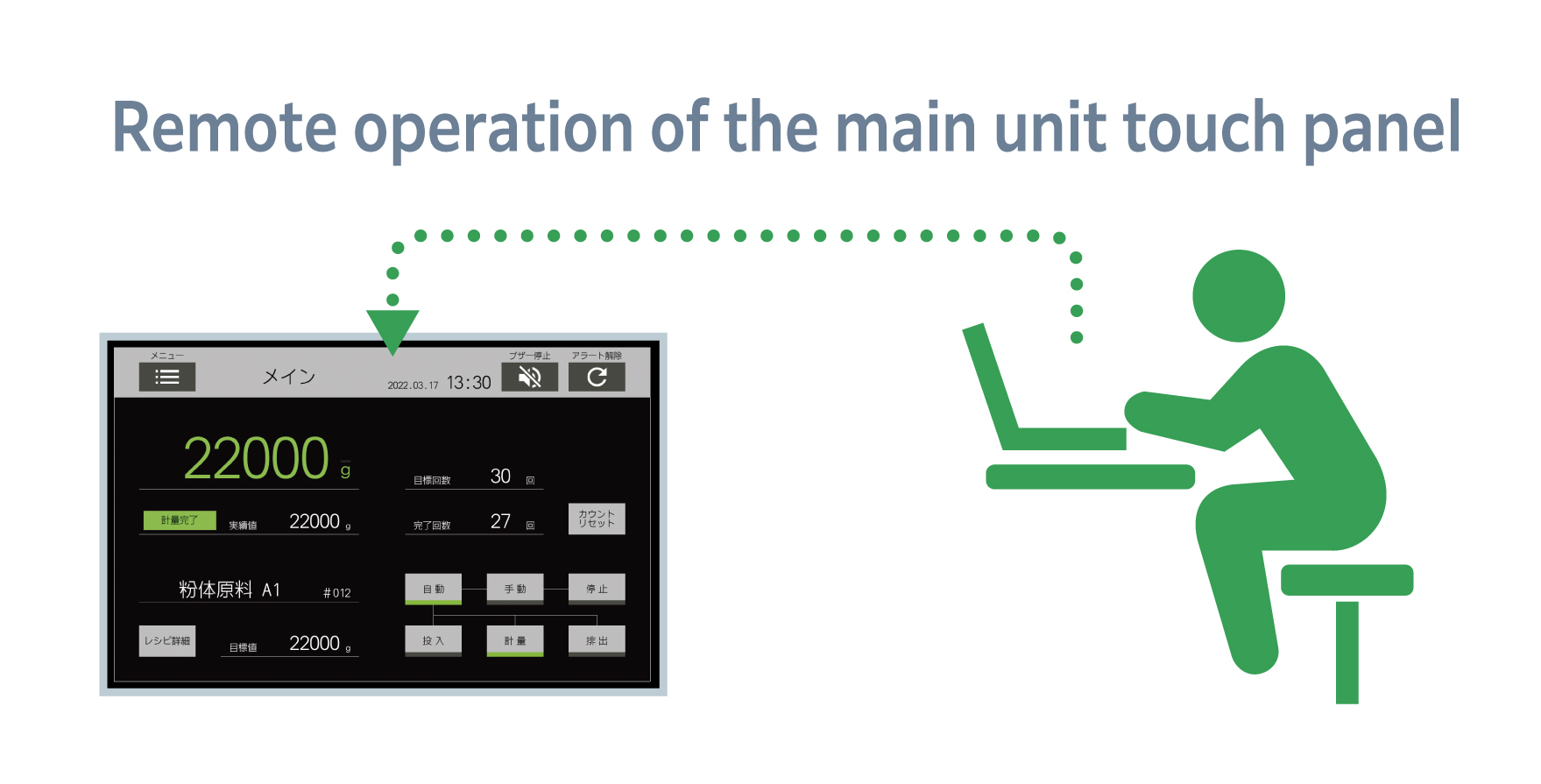

Remote operation of the main unit touch panel

By connecting the Divider Scale main unit and an office PC via a LAN, the same operations as on the machine’s touch panel can be performed from the office. With a system in which “recipe registration is performed in the office and the site operator only presses the start switch,” recipe information can be protected further.