Case Studies

Case Examples

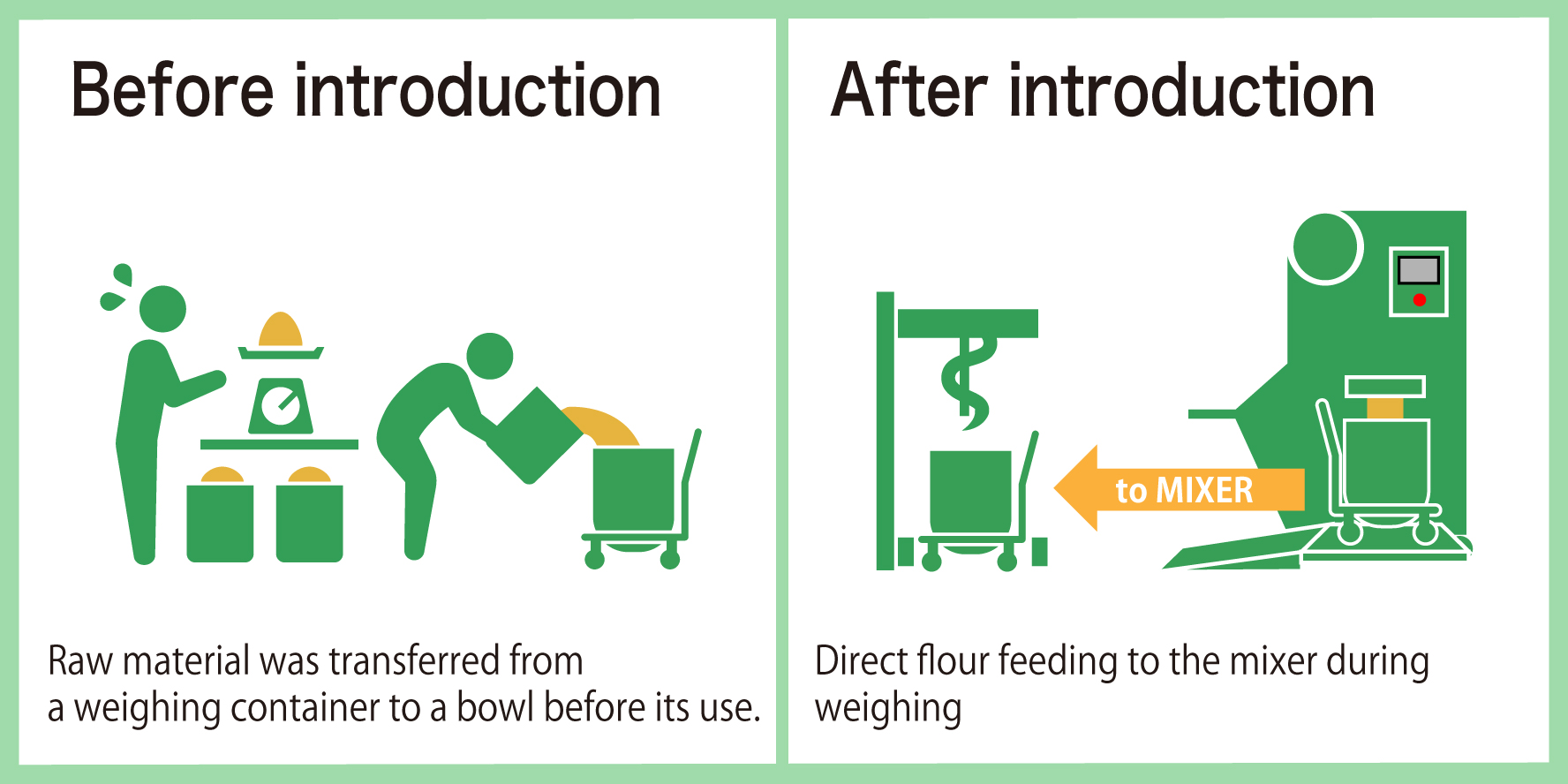

Direct powder feeding from the automatic-weighing machine to a movable bowl for the mixer

Weighing Process

Type of Industry

Confectionery manufacturer

Introduced Products

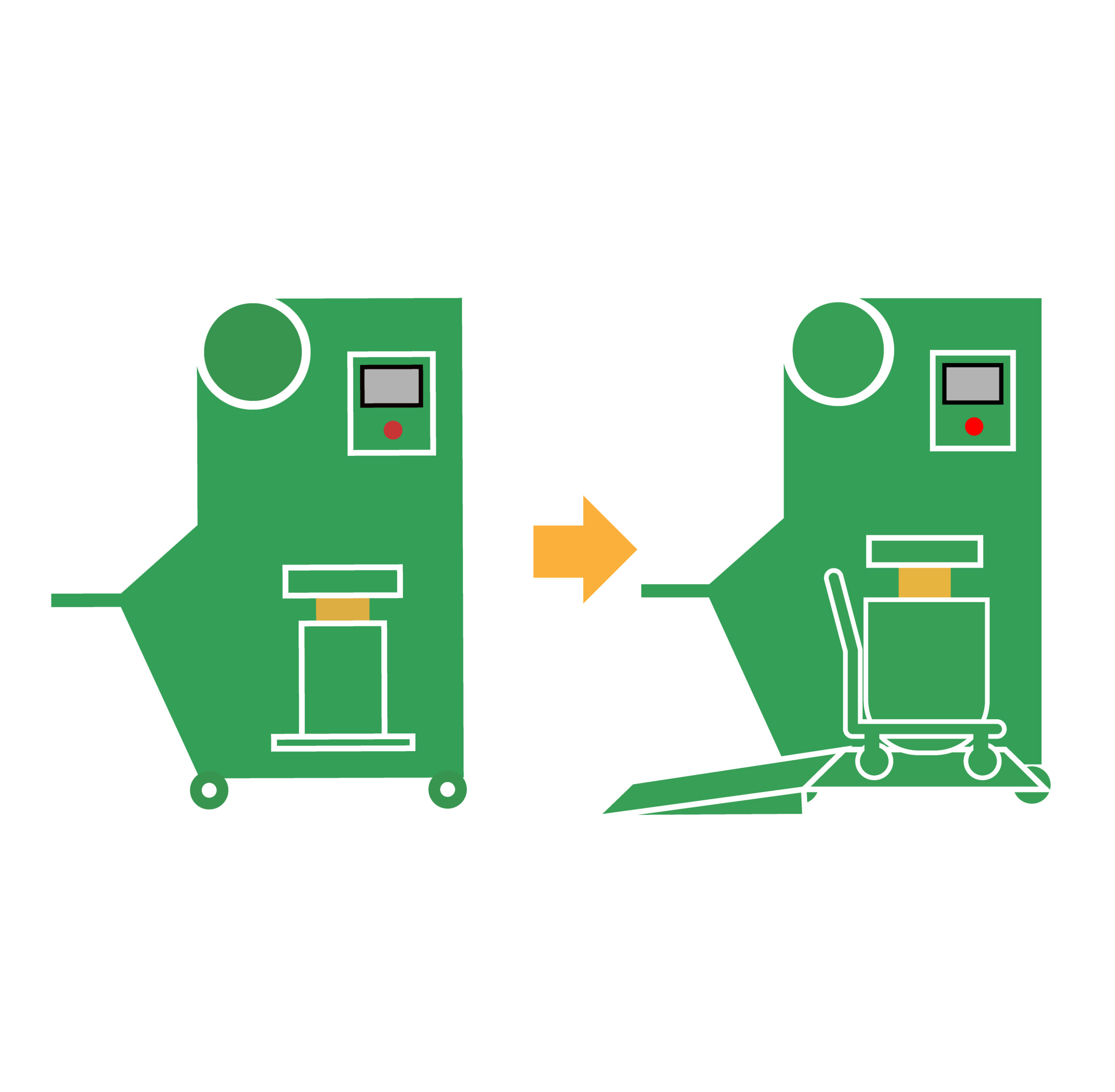

Divider Scale Hybrid Floor scale specifications

Customer requests

Wishing to eliminate manual weighing and manual transfer to a bowl

This request came from a castella cake manufacturer. Previously, they manually weighed small portions of flour into a container, then transferred it to a bowl for the mixer before carting it to the mixer. This raised concerns about manual measurement errors, the effort required to transfer the flour, and the risk of dust scattering as well as contamination by dirt and debris. They consulted TSUKASA to find a solution for these issues.

Suggestions from TSUKASA

Addressing these issues by automated weighing and direct flour feeding to a bowl

We proposed fully automating the weighing process using the automatic weighing machine "Divider Scale Hybrid." The customer further requested us to "reduce one more step," so we proceeded with the development of "floor scale specifications" that eliminate the need to transfer from a weighing container to a bowl for the mixer.

New workflow

A bowl for the mixer is put on a cart, which is set beside the weighing machine.

↓

Automatic weighing is performed simultaneously with flour feeding using the scale installed under the cart.

↓

The cart is moved directly to the mixer.

↓

Automatic weighing is performed simultaneously with flour feeding using the scale installed under the cart.

↓

The cart is moved directly to the mixer.

Results of introduction

Eliminating the need to transfer to a bowl provides a variety of benefits!

Significant reduction in work time and improved labor efficiency

With the introduction of the "Divider Scale Hybrid," the time required to weigh the same amount of powdered raw material was reduced by approximately half. The burden on the operators has been significantly reduced. Furthermore, the adoption of "floor scale specifications" eliminated the transfer process from a weighing container to a bowl, resulting in labor savings equivalent to one additional worker.

Prevention of foreign matter contamination and dust generation during transfer

When an operator abruptly opened a weighing container and transferred its contents into a bowl, there were concerns about flour dust scattering and contamination by dirt and debris. With the "floor scale specifications," all you have to do is move the cart and set a bowl to the mixer, eliminating such concerns.

Installed directly in the weighing room

The Divider Scale Hybrid is compact in size, allowing its installation inside the weighing room where traditional manual weighing used to be performed. Since it is equipped with multiple functions, there is no need to separately prepare a sieving machine or a dust collector.

Dust collection, sieving, and magnetic foreign object removal all in one machine!

It can also be additionally installed on an existing "Divider Scale Hybrid"!