Case Studies

Case Examples

Automatic weighing with high efficiency and space saving

Weighing Process

Type of Industry

Processed fishery foods manufacturer

Introduced Products

Divider Scale Terminal Detachable Model

Background and problem

Improve the efficiency of weighing the day before by a lot of people

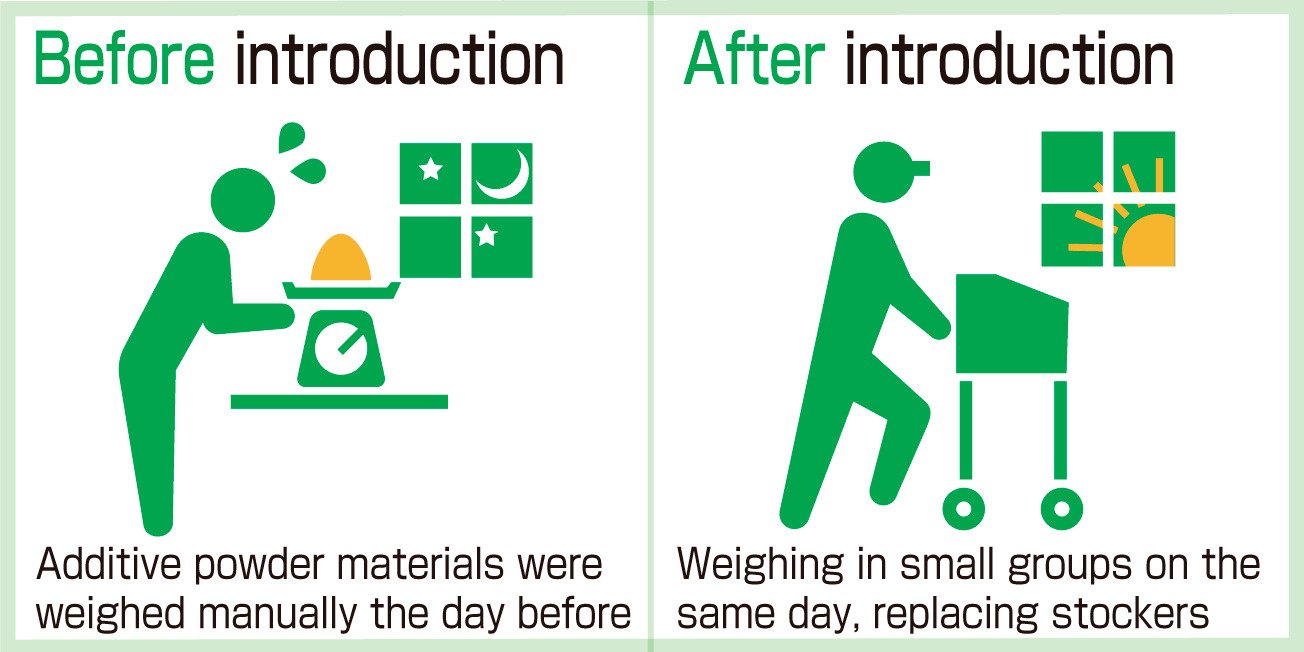

In the manufacture of processed fishery food products, more than ten kinds of additive powder materials such as seasonings were used. The weighing of the powder to be used the next day was done manually by five dedicated staff, which required a full day of work. The customer considered automation due to labor shortages, but there was no space in the factory to place large machines. So they asked TSUKASA, "Can you do something?".

Suggestions from TSUKASA

Weighing equipment with a detachable stocker saves space and enables automation

We proposed the "Divider Scale Terminal Detachable System" from which material stockers can be detached at up to four locations and additive materials can be changed for mixing. We provided ten stockers for two Divider Scales for more efficient rotation.

Why TSUKASA was chosen

⚫︎Efficient use of factory space without using conveyors

Only TSUKASA provides the automatic dividing and weighing equipment from which multiple stockers can be detached. It saves space in the factory because it is not necessary to transport containers on conveyors with multiple weighing machines side-by-side.

⚫︎Image recognition to prevent erroneous feeding is also available

Image recognition systems can also be installed to prevent mistaking of additive materials. The stocker is unlocked only if the label of the material bag taken with the camera matches with the material set for that feeding port.

⚫︎Careful test-drive before deployment

We borrowed materials from our customer, tested them internally in TSUKASA, and tested them also at our customer's factory repeatedly to demonstrate "how efficient they can be."

Only TSUKASA provides the automatic dividing and weighing equipment from which multiple stockers can be detached. It saves space in the factory because it is not necessary to transport containers on conveyors with multiple weighing machines side-by-side.

⚫︎Image recognition to prevent erroneous feeding is also available

Image recognition systems can also be installed to prevent mistaking of additive materials. The stocker is unlocked only if the label of the material bag taken with the camera matches with the material set for that feeding port.

⚫︎Careful test-drive before deployment

We borrowed materials from our customer, tested them internally in TSUKASA, and tested them also at our customer's factory repeatedly to demonstrate "how efficient they can be."

Results of introduction

⚫︎Work reduction from "5 people x 1 day" to "2 people x half day"

If you start weighing with two people in the morning, it will be in time for the day's first run of the mixer. The weighing for the day ends in the morning and other work can be done in the afternoon, mitigating labor shortages and tightness in daily work.

⚫︎Improved food traceability

Because the equipment keeps a history of "how many kilograms and what kind of raw materials were weighed on a particular date and time," in the event of a problem, you can now trace it back.

⚫︎No need to re-check before feeding

The customer has been rechecking the type of material before feeding it into the stocker. With the introduction of an image recognition system, this work was eliminated.

If you start weighing with two people in the morning, it will be in time for the day's first run of the mixer. The weighing for the day ends in the morning and other work can be done in the afternoon, mitigating labor shortages and tightness in daily work.

⚫︎Improved food traceability

Because the equipment keeps a history of "how many kilograms and what kind of raw materials were weighed on a particular date and time," in the event of a problem, you can now trace it back.

⚫︎No need to re-check before feeding

The customer has been rechecking the type of material before feeding it into the stocker. With the introduction of an image recognition system, this work was eliminated.