Case Studies

Case Examples

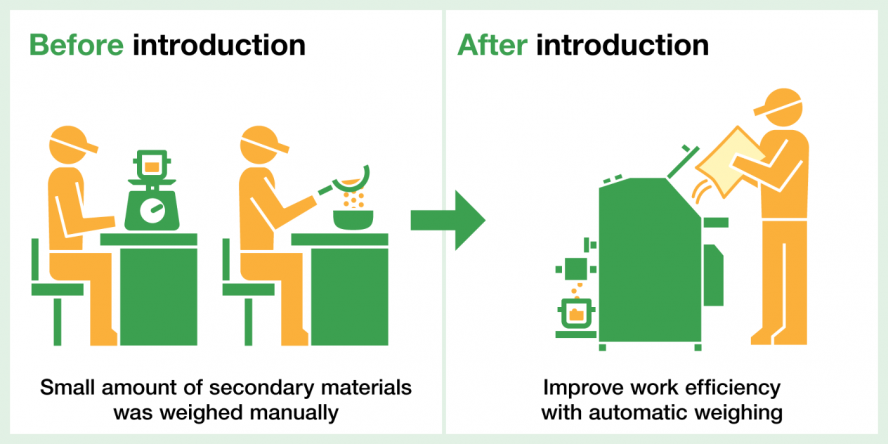

Improve efficiency by automatically weighting small amount of powder materials

Weighing Process

Type of Industry

Food (bread) manufacturer

Introduced Products

Divider Scale

Background and problem

We would like to review our process of weighting small amount which takes time and labor.

A bread manufacturer had equipment for automatically feeding main materials and removing foreign materials, but manually weighed small amount of secondary materials. The second materials required frequent weighing and took time for sieving, so they needed to improve work efficiency.

Results of introduction

Divider Scale A high performance, space-saving automatic weighing equipment

We proposed Divider Scale-Dumping Model in order to solve time taken for weighing and sieving. Our Divider Scale is a hybrid product that not only sieves and automatically weighs materials manually fed or stocked, but also has a built-in dust collector that collects magnetic foreign matters with magnets and prevents dust from scattering during weighing and discharge.

Reduce labor required for weighing secondary materials

The automatic weighing equipment solved work load on weighing and sieving.

Furthermore, both weighing and sieving can be done in this equipment so the manufacturer was satisfied that it saves spaces, is easy to dissemble, clean and handle, and has excellent maintainability.

Furthermore, both weighing and sieving can be done in this equipment so the manufacturer was satisfied that it saves spaces, is easy to dissemble, clean and handle, and has excellent maintainability.