Case Studies

Case Examples

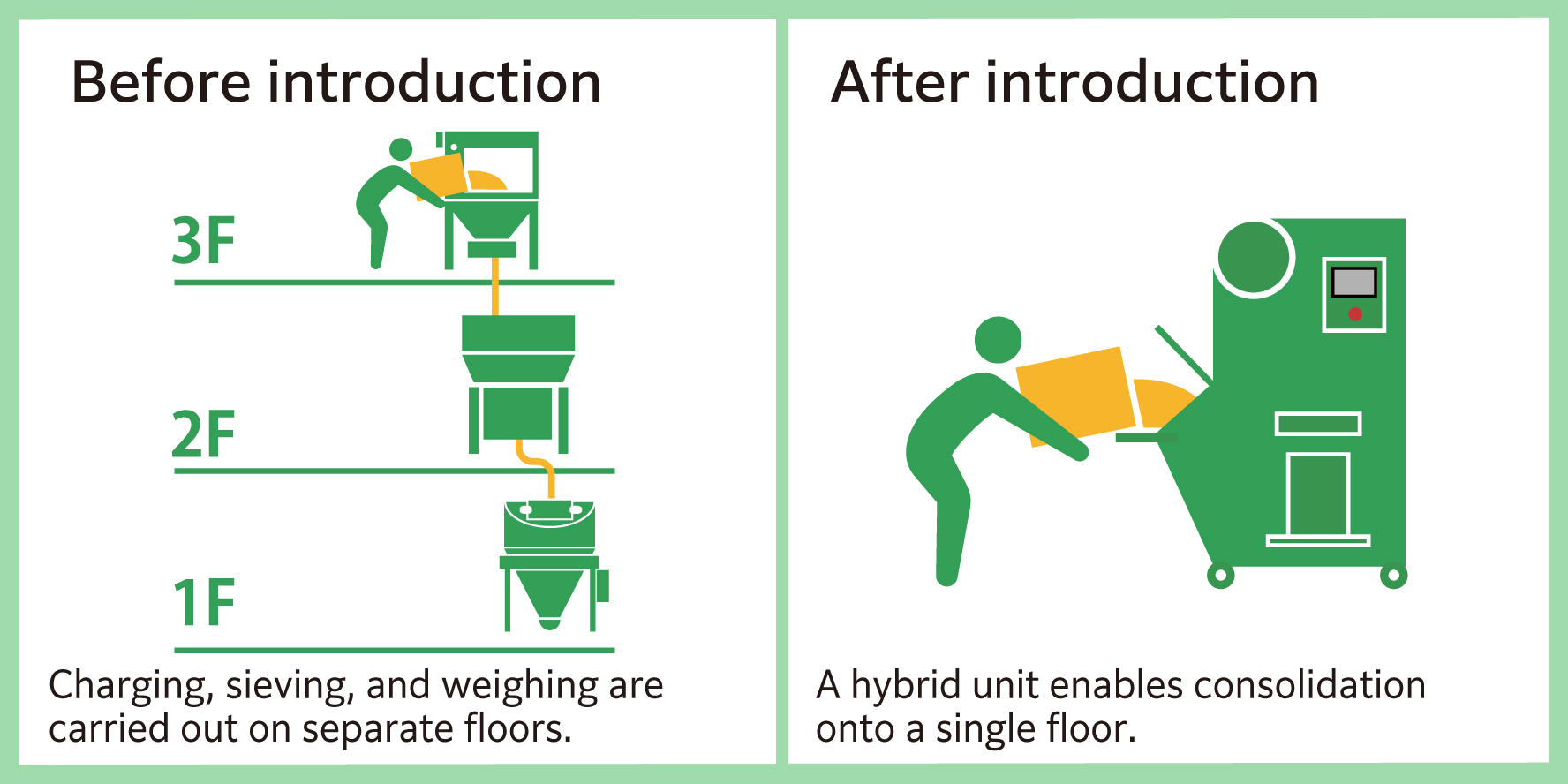

Automatic weighing consolidates units (equipment) from the 1st to 3rd floors onto a single floor.

Weighing Process

Type of Industry

Food manufacturer

Introduced Products

Divider Scale Hybrid

Customer requests

We want to consolidate the weighing processes currently separated across the 1st to 3rd floors.

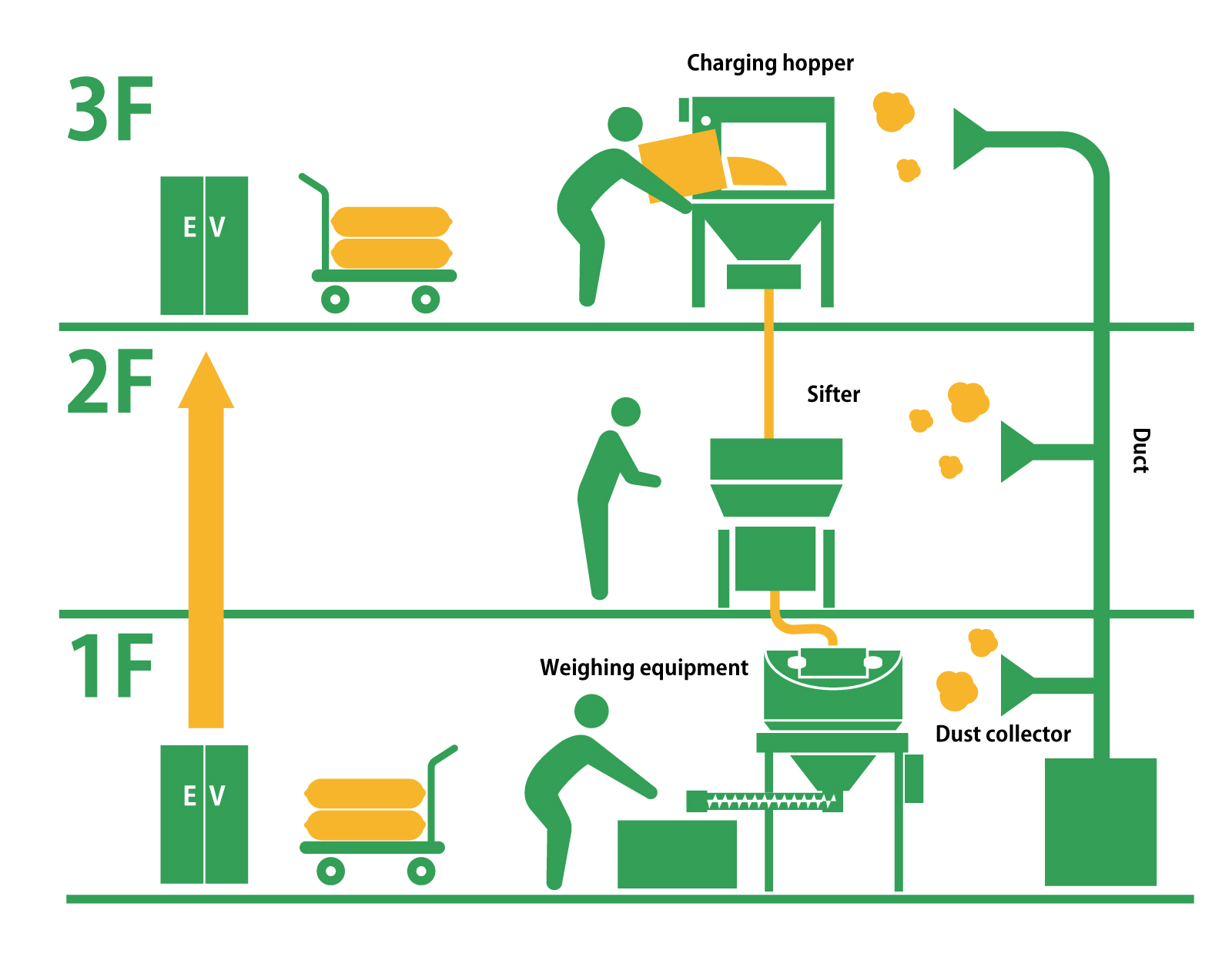

“Currently, raw material bags are lifted to the third floor and fed into a hopper, then transferred to the second floor by chute transport (gravity drop) for sieving and foreign matter removal, and subsequently dropped to the first floor for weighing. Recently, our factory has become cramped, and we are wondering whether the overall process can be made more compact through the introduction of new equipment.” We have received this request from a customer who has been running a food factory for decades.

Suggestions from TSUKASA

Introduction of a hybrid unit and a pneumatic conveyance line

We have proposed to the customer the introduction of a “Divider Scale Hybrid” and a pneumatic conveyance line. Unlike chute transport, this system does not require units to be arranged vertically; by installing a single unit in the first-floor space (the former weighing room), it delivers multiple functions, including charging, dust collection, sieving, storage, magnetic foreign matter removal, and weighing. As a result, the space previously occupied by the units on the second and third floors was completely freed up.

▲Divider Scale Hybrid

New uses for the second- and third-floor spaces have become possible.

As a result of this improvement, the customer can now consider effectively utilizing the freed-up space on the second and third floors, such as expanding other process lines, installing new equipment, or using the space as break rooms or storage areas.

Reduced hassle of managing and cleaning equipment

Previously, management staff were required for the equipment on each of the first, second, and third floors; however, consolidating the equipment into a single unit has made it possible for one person to handle the operation. Previously, dust dispersion occurred each time raw materials were handled manually; however, all operations have now been integrated in-line, eliminating the need for cleaning.

Significant reduction in raw material loss

Powdered raw materials collected by standalone dust collectors are treated as waste and must be disposed of as industrial waste at additional cost. The Divider Scale Hybrid automatically reuses raw materials collected inside it, enabling a thorough reduction in raw material loss.

It is also very cost-effective.

In this customer’s case, the installation took about half a day. Compared with installing separate machines (approximately five to six types) for steps from raw material charging to weighing, the customer reduced the cost to about one-fifth. Of course, in-line integration has also eliminated the need to install a duct on each floor.