Case Studies

Case Examples

Shorten workhours with easy assembly of piping

Valves and Piping parts

Type of Industry

Food company

Introduced Products

Dacton parts

Background and problem

We would like to renew piping without taking too much construction time

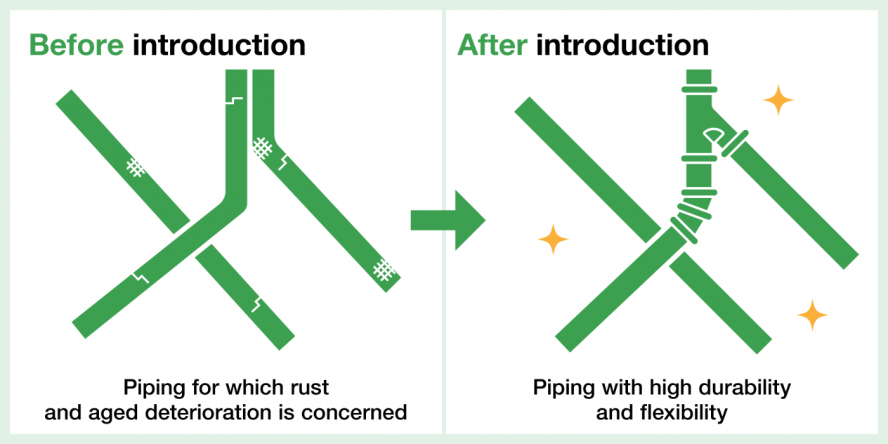

A food company used steel pipes for piping and had a problem that their construction work and workhours take long time.

They are worried about rust caused by aged deterioration and corrosion resistance, so they requested piping with more appropriate materials than steel pipes they were using.

They are worried about rust caused by aged deterioration and corrosion resistance, so they requested piping with more appropriate materials than steel pipes they were using.

Results of introduction

Dacton parts that can be easily assembled

We proposed our Dacton parts that can be used in free combinations from a wide variety of part types manufactured for each purpose.

They choose to install our Dacton parts, because they can be easily attached and detached with easy assembly mechanism and have many related parts (such as inspection doors and directional control valves that can change destinations).

They choose to install our Dacton parts, because they can be easily attached and detached with easy assembly mechanism and have many related parts (such as inspection doors and directional control valves that can change destinations).

Completed efficient piping composed of suitable parts

Ease of handling each one of parts and abundance of parts shortened maintenance management and workhours. They are also satisfied with higher durability of the product than that of steel pipes.