Case Studies

Case Examples

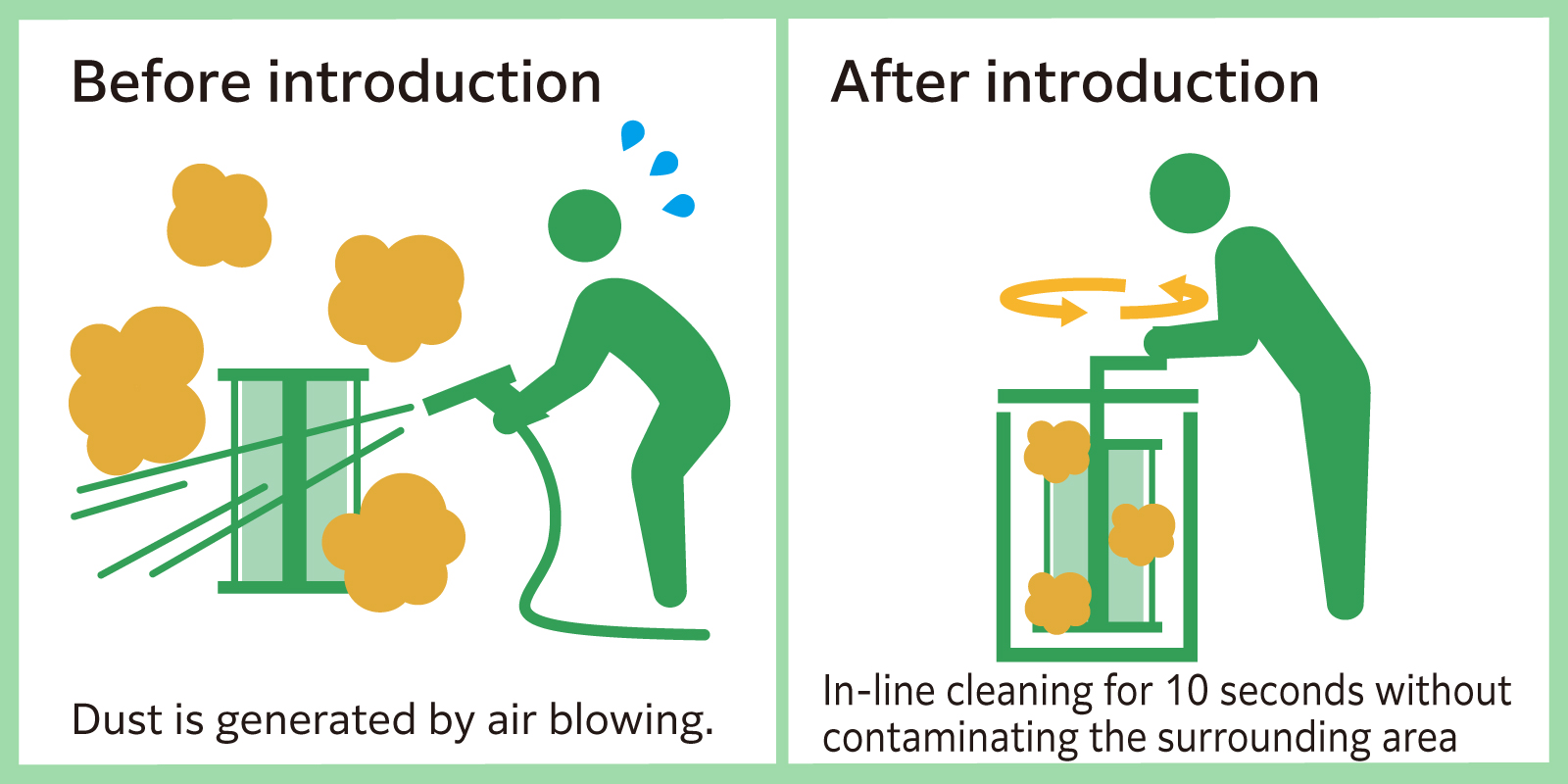

Cleaning of the sieve mesh of a sieving machine without dust dispersion

Sifting and Foreign-material Removal Process

Type of Industry

Food manufacturer

Introduced Products

Sieve cleaner (for LINESIFTER® and PowSifter)

Customer requests

Elimination of powder scattering during sieve cleaning

When using air blowing or a vacuum cleaner directly for sieve cleaning, powder inevitably scatters and contaminates the surrounding area. Therefore, after cleaning, the operator would sweep the floor, or carry the sieve to a location where powder scattering was acceptable for cleaning. We received a request from a customer to find a way to eliminate this hassle.

Suggestions from TSUKASA

Zero dust dispersion with the “Sieve Cleaner”

Once the sieve removed from the sieving machine is set in the “Sieve Cleaner,” all subsequent cleaning work is done in-line, so there is no need to worry about dust being blown up by air.

Easy operation—simply turn the handle for 10 seconds

"(1) Connect the vacuum cleaner nozzle to the Sieve Cleaner.

(2) Set the sieve in the Sieve Cleaner.

(3) Start the vacuum cleaner, then open the air valve.

(4) Manually rotate the upper handle for approximately 10 seconds.

(5) Close the air valve, then stop the vacuum cleaner.

(6) Remove the sieve and check for tears."

(2) Set the sieve in the Sieve Cleaner.

(3) Start the vacuum cleaner, then open the air valve.

(4) Manually rotate the upper handle for approximately 10 seconds.

(5) Close the air valve, then stop the vacuum cleaner.

(6) Remove the sieve and check for tears."

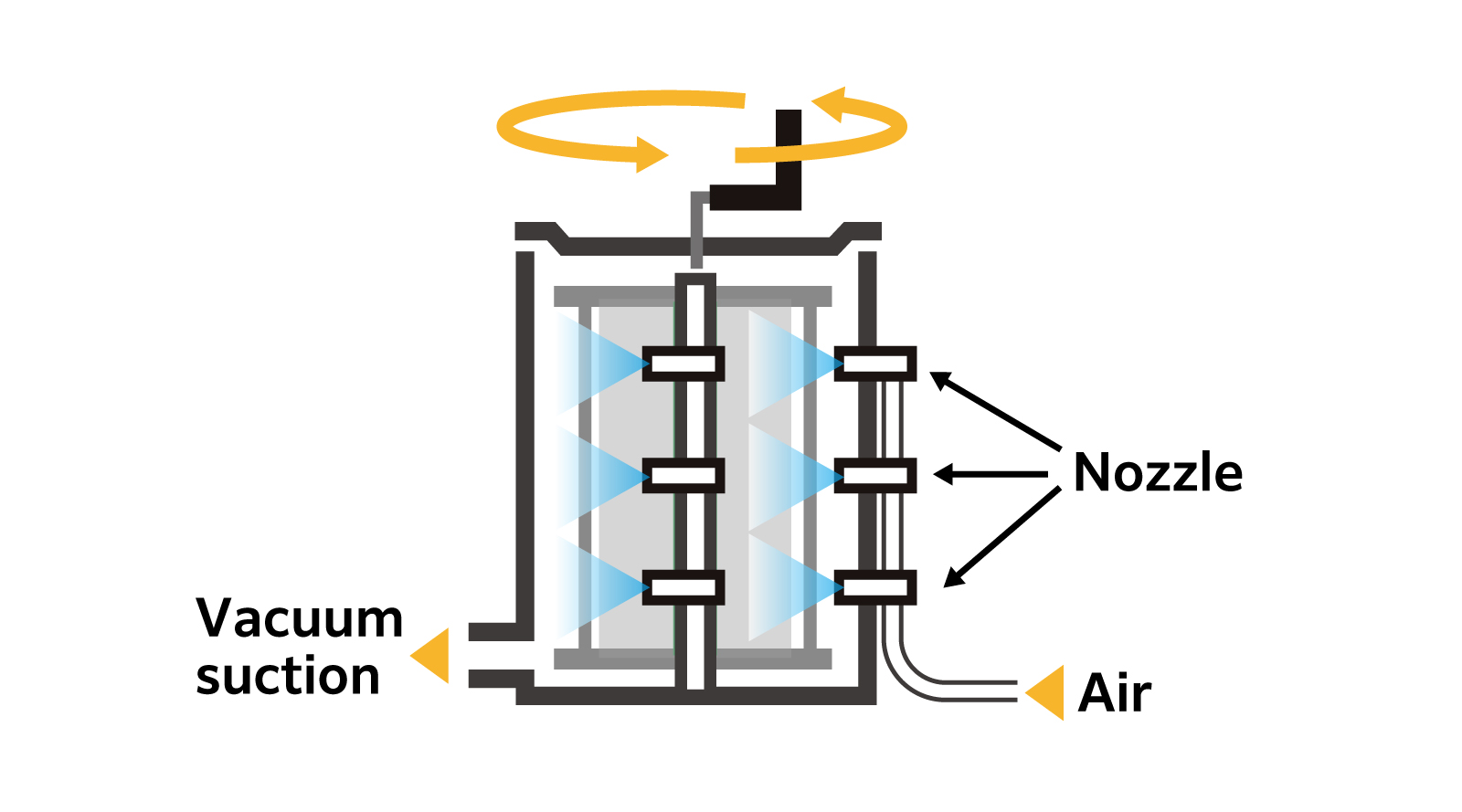

Powerful cleaning by air blow from the nozzle

Air is blown onto the installed sieve. Handle operation rotates the sieve to clean evenly. The exhaust air is captured by the vacuum cleaner.

Longer sieve service life without damaging the sieve

There is no risk of damaging the sieve by rubbing it with a vacuum cleaner head, which extends the service life of the sieve.

One cleaner adaptable to multiple sieves

The “Sieve Cleaner” is portable. Using a single unit can clean multiple sieving machines operating within the factory.