Case Studies

Case Examples

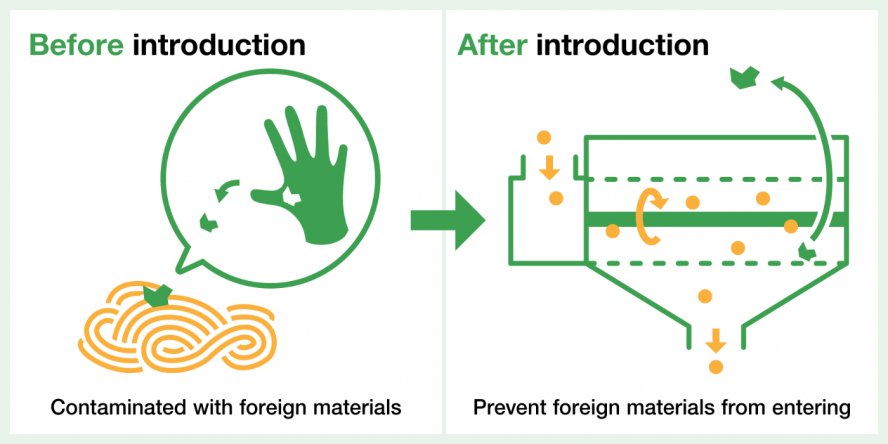

Prevent foreign materials from entering without changing manufacturing processes

Sifting and Foreign-material Removal Process

Type of Industry

Food (noodle) manufacturer

Introduced Products

LINESIFTER

Background and problem

We would like to improve the feeding materials process, which has a high chance of letting foreign materials enter.

We were contacted by a noodle manufacturer about a process where wheat flour (material) is put into a feeding hopper from paper bags by hand and conveyed to a mixer by means of pneumatic conveyance.

They controlled hygiene in the plant, but still had a risk of letting foreign materials enter during feeding, which was a problem for food safety.

They controlled hygiene in the plant, but still had a risk of letting foreign materials enter during feeding, which was a problem for food safety.

Results of introduction

LINESIFTER® which minimizes changes to existing processes

The company wanted to prevent foreign materials from entering, while minimizing changes to existing work processes and material reception equipment. Therefore, we suggested to install a LINESIFTER®, which can remove foreign materials, crush clumps, and sieve efficiently just by installing it to the piping in the pneumatic conveyance line.

Parts (sieves) of the LINESIFTER® can be easily inspected and replaced, and washed with water.

Parts (sieves) of the LINESIFTER® can be easily inspected and replaced, and washed with water.

A piece of rubber was collected safely

A piece of rubber from a rubber glove a worker wore was collected from a LINESIFTER, which prevented it from entering products. The worker did not notice his rubber glove was torn, so it is likely the foreign material would enter products if the LINESIFTER® was not there.