Case Studies

Case Examples

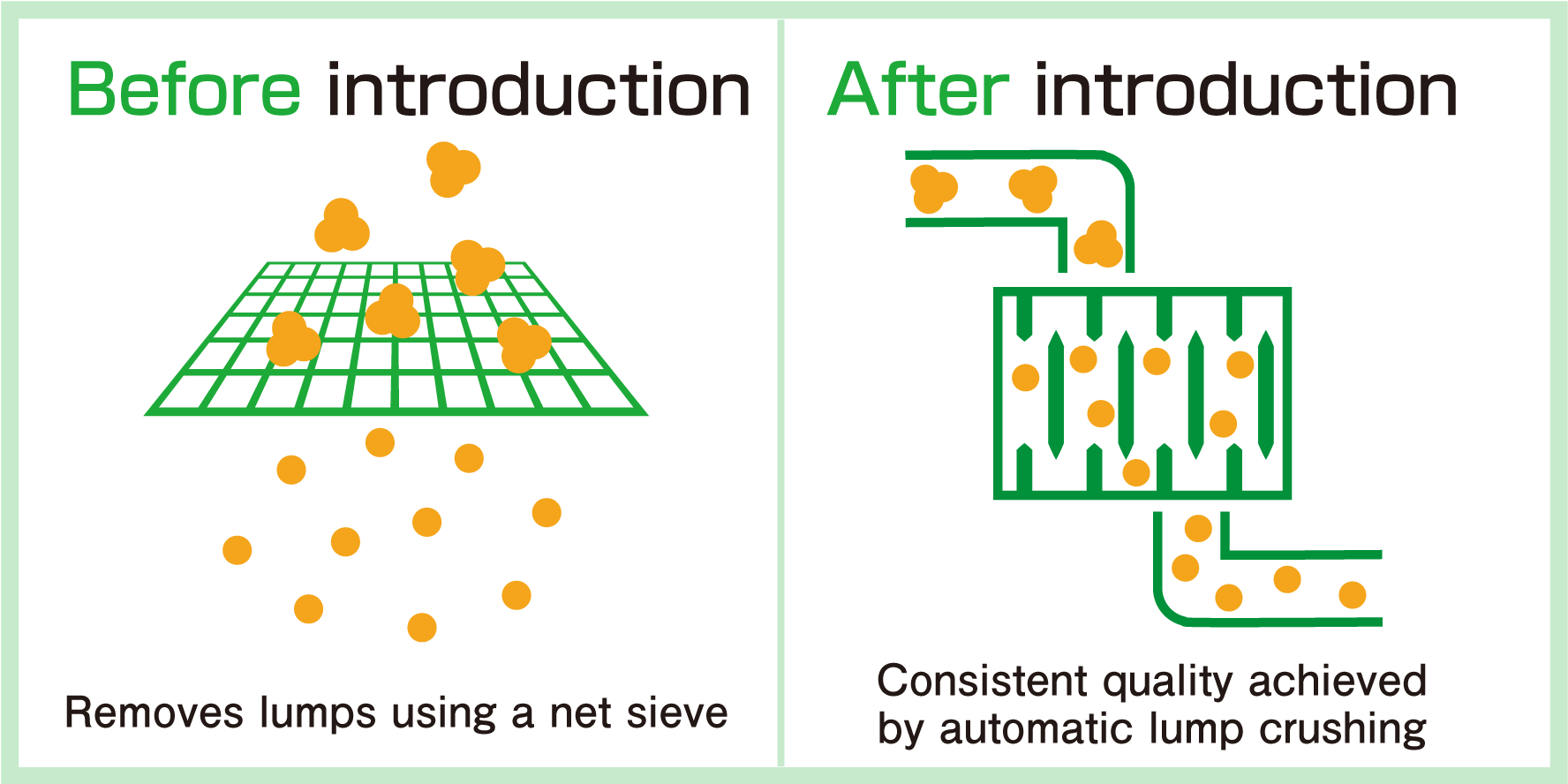

Stabilizing Quality by Crushing Lumps of Confectionery Materials

Crushing and Milling Process

Type of Industry

Confectionery manufacturer (chocolate factory)

Introduced Products

PowCrusher

Background and problem

We would like to eliminate the lumps in cacao mass when it is placed into a mixer

At a chocolate factory, a plan to fully automate the line by pneumatic conveyance was underway. One issue was that lumps of cacao mass, which is rich in oil, were easily formed during conveyance. As a result, the quality of the cacao mass became inconsistent when mixed with sugar and milk.

The customer of the factory consulted with us, stating "We are currently carrying out sifting over a net to get rid of lumps and prolong the mixing time to obtain a consistent quality. Do you have any solutions in terms of streamlining this operation?"

The customer of the factory consulted with us, stating "We are currently carrying out sifting over a net to get rid of lumps and prolong the mixing time to obtain a consistent quality. Do you have any solutions in terms of streamlining this operation?"

Suggestions from Tsukasa

Automatic crushing through the incorporation of a PowCrusher into the line

We investigated a method using a PowCrusher. Before the ingredient was put into a mixer, any lumps were crushed with the equipment's internal rotating and fixed blades. Using a sample of cacao mass provided by the customer, we repeated crushing tests to ensure consistent quality before deciding to use this method.

Why TSUKASA was chosen

Small size makes it easy to be integrated into a line

The best feature of TSUKASA's PowCrusher is its compact size—it is smaller than those of other manufacturers, making it easier to integrate into the design of lines. It can also be easily added to existing lines.

Results of introduction

Reduction of waste through consistent quality

Compared to manual lump removal, the quality has become consistent, and waste was significantly reduced which served as a cost-saving measure.

Prevention of contamination by foreign substances

Since there is no human involvement between the tank and mixer, and all work was done in-line, and prevention of foreign substances getting contaminated was realized.

Reduction of the number of operators across the line

The number of operators was reduced line-wide, contributing to solving a labor shortage issue in the manufacturing site.