Case Studies

Case Examples

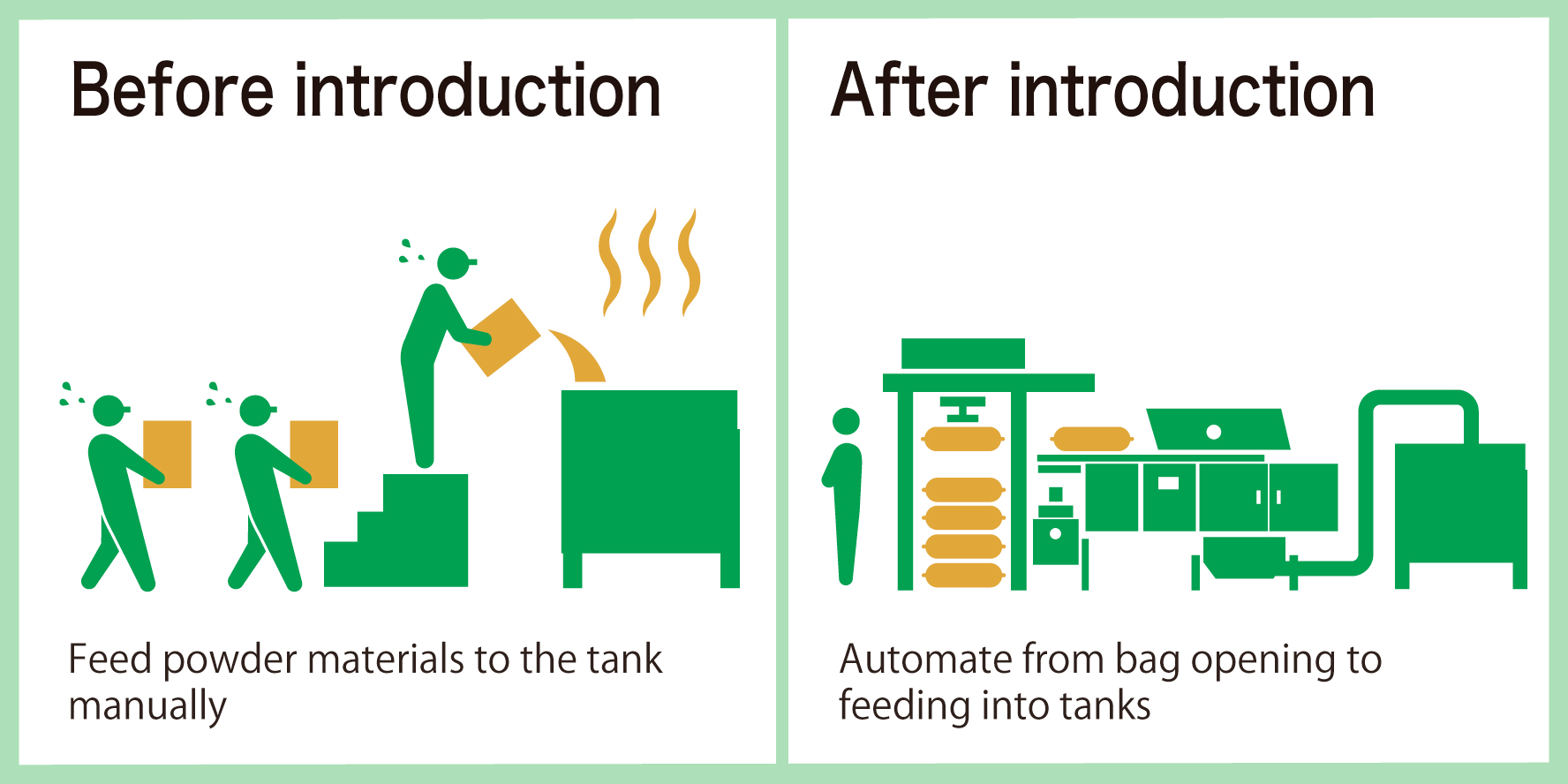

Automate the feeding of powders such as skim milk powder to the dissolving tank

Material Receiving and Powder Feeding Process

Type of Industry

Dairy manufacturer

Introduced Products

Automatic bag opening System, etc.

Background and problem

There are also challenges with heavy labor, the working environment, and removing foreign material

We had a customer who was manually feeding the main raw materials (such as skim milk powder) and secondary materials in paper bags directly into the dissolving tank. Not only is this hard work, but the powder-mixed steam would make their work clothes sticky. Furthermore, they were constantly worried about the occurrence of human error, such as feeding the wrong materials.

In addition, foreign material removal was not carried out at the powder material stage, but rather at a much later process, when the raw materials had turned into a liquid.

In addition, foreign material removal was not carried out at the powder material stage, but rather at a much later process, when the raw materials had turned into a liquid.

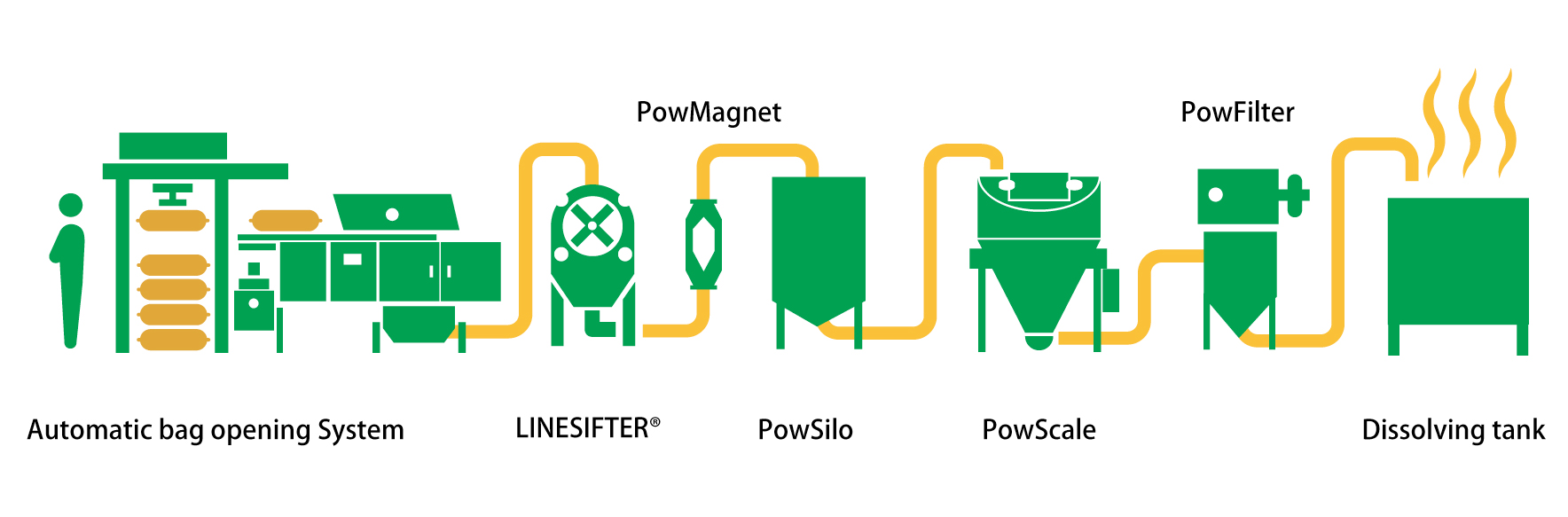

TSUKASA Automated Line Construction Example

Main raw materials are handled fully automated, secondary materials are handled manually for flexibility

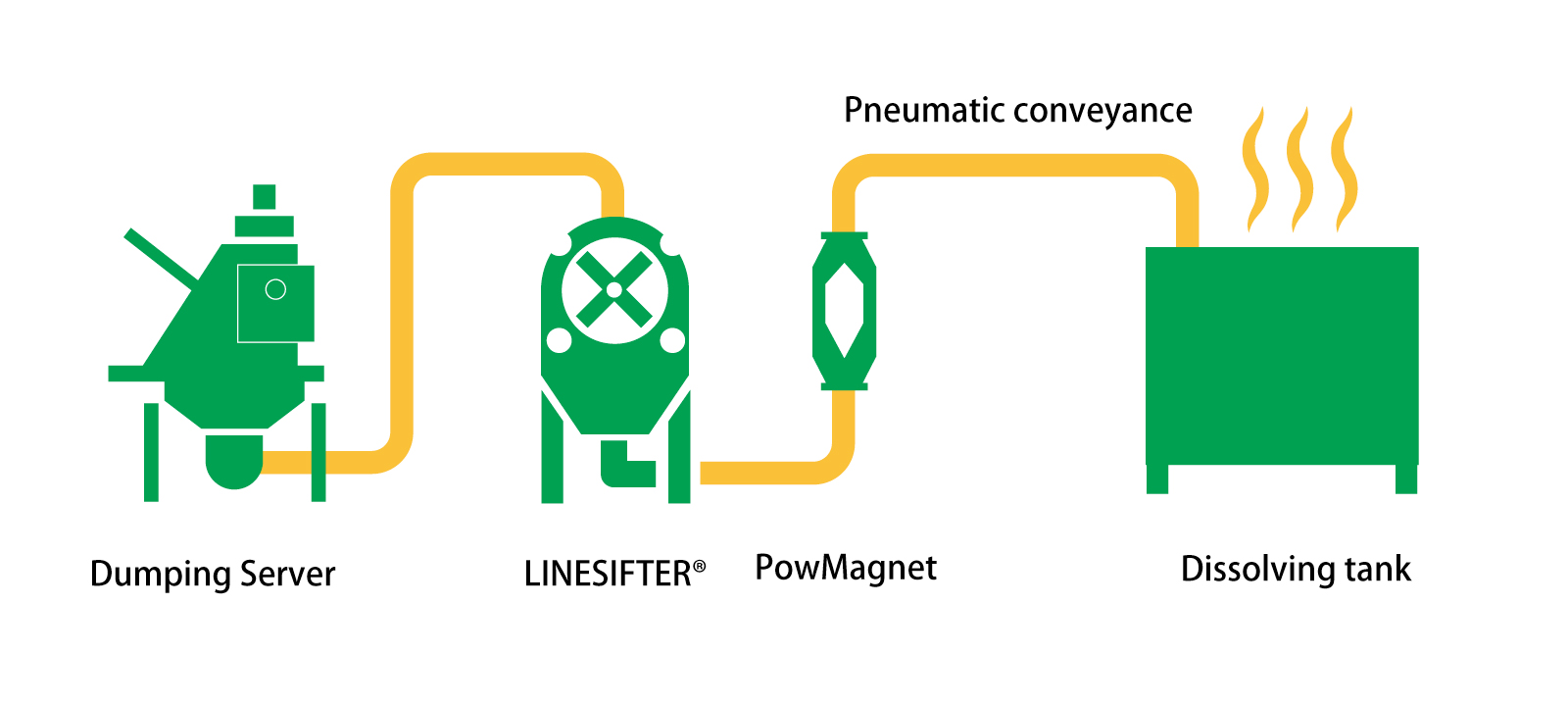

For the main raw materials, the process from bag opening to feeding them into the dissolving tank is fully automated using a pneumatic conveyance line. For the secondary materials, we proposed a system that would enable manual feeding to the line, allowing for flexible response to recipe changes, etc.

Main raw material supply line

Powder raw materials used in large quantities, such as skim milk powder

Secondary material supply line

Functional ingredients for each customer's product

Additionally, we can flexibly configure production lines to suit the circumstances of the customer's factory!

Results of introduction

Labor saving and error reduction through automation

By automating the "system that leaves everything to the operators," even the transportation and opening of raw material bags and line supply can also be automated. This has also contributed to preventing back pain, which accounts for nearly 60% of occupational illnesses in food factories.

Greatly improved working environment

This eliminated the need for workers to stand next to the dissolving tank, and prevented the workers clothes from becoming sticky. The improved working environment also helped with recruitment, reducing concerns that employees would quit quickly.

Contributions to thorough reduction of foreign material contamination

Foreign material is removed from the powder stage (non-magnetic and magnetic), and then in the liquid state it is passed through a strainer to greatly reduce the possibility of foreign material being mixed in. This also enabled the prevention of quality deterioration during processing.

Message from TSUKASA

We recommend removing foreign material from the powder stage!

We think that many liquid-related manufacturers believe that using a strainer at the final stage is sufficient to remove foreign material. However, as a comprehensive manufacturer of powder equipment, TSUKASA recommends double checking by removing foreign material at the powder stage!