Case Studies

Case Examples

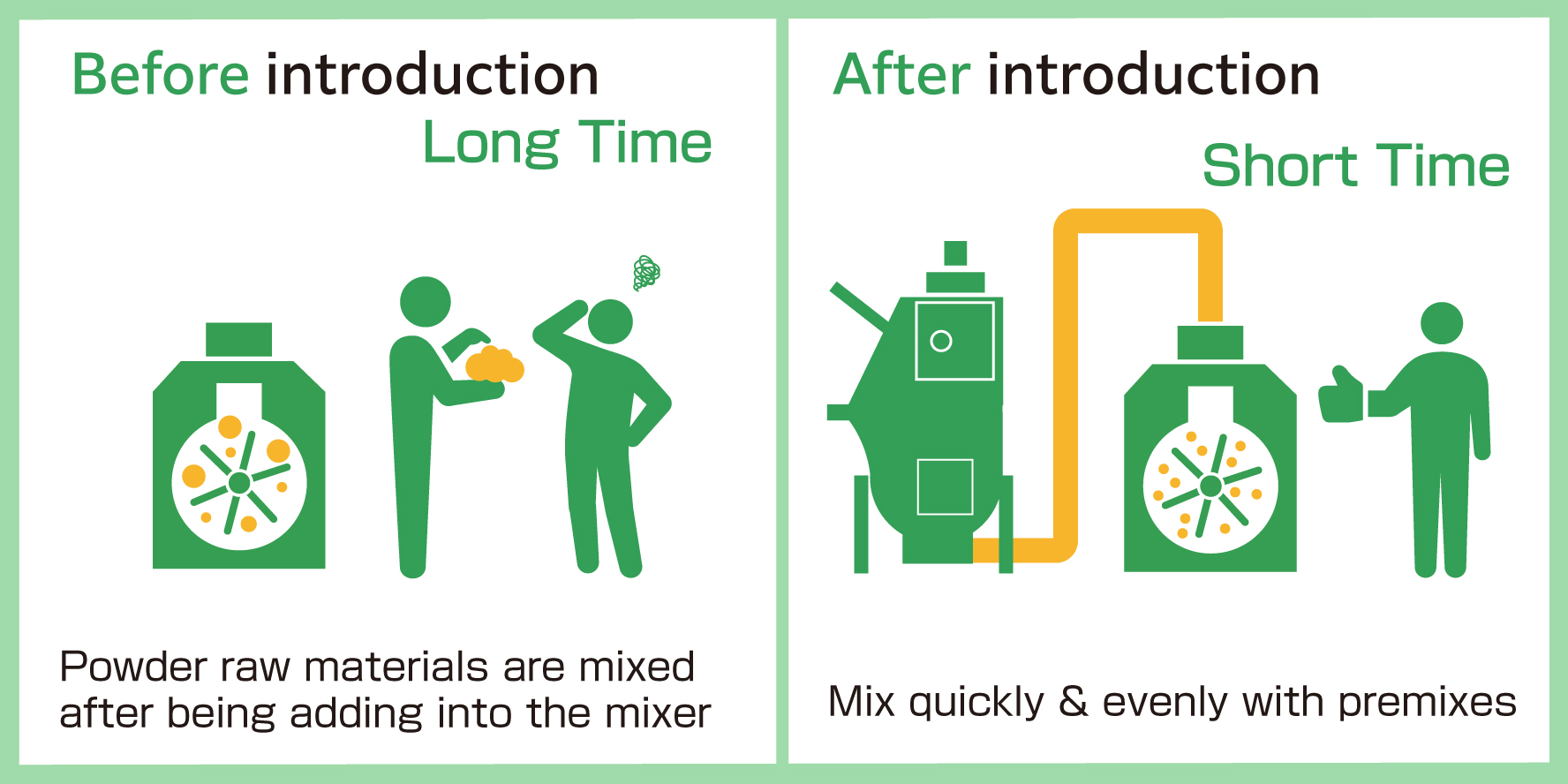

The mixing time in the noodle dough mixer is greatly reduced

Material Receiving and Powder Feeding Process

Type of Industry

Noodle manufacturer

Introduced Products

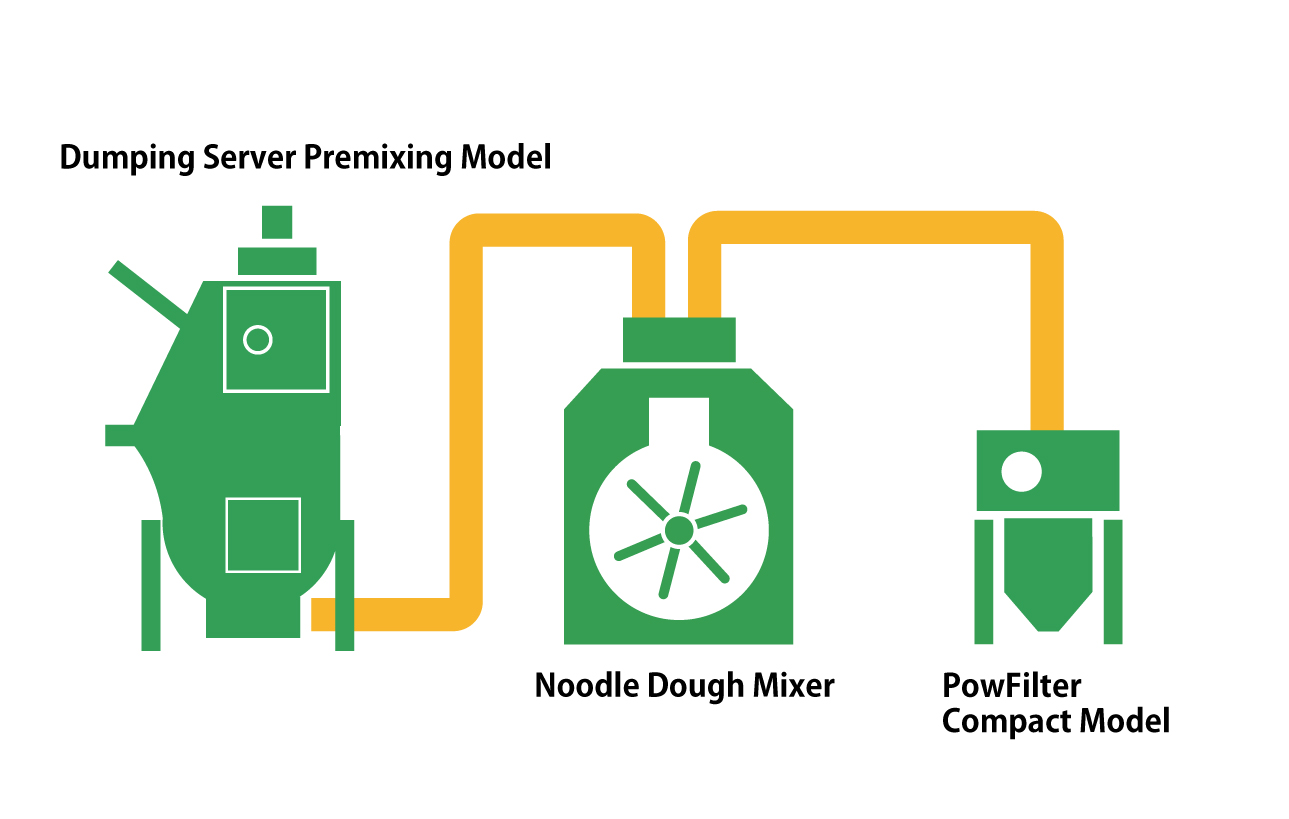

Dumping Server Premixing Model, etc.

Customer requests

Mixing the powder takes time and it does not mix evenly

We had a consultation with a customer who stated, "Multiple powders, such as the main ingredient flour and auxiliary ingredients, are mixed with a noodle dough mixer. It does not mix evenly, so can something be done about it?" In addition, they had previously considered automating the feeding of flour to the noodle dough mixer, but could not install a receiver due to the lack of ceiling height.

In this customer's factory

● Various types of raw materials are used

● A wide variety of noodle products are also available

● There is a lack of ceiling height

● A wide variety of noodle products are also available

● There is a lack of ceiling height

Suggestions from TSUKASA

Introduction of equipment that can premix in a few minutes

We suggest the "Dumping Server Premixing Model" that can manually add multiple powder raw materials to achieve high-precision mixing. We made it possible to make premixes in just a few minutes, which was difficult with noodle dough mixers. Additionally, it is now possible to evenly disperse and mix trace additives.

Pneumatic conveying directly feeds to the noodle dough mixer

We have introduced a system to feed premixed ingredients directly into the noodle dough mixer by pneumatic conveyance. Since there is no need to install a receiver on top of the mixer, it fits neatly into the current factory space where the ceiling height is not sufficient.

Air treatment and dust collection are also supported

Since "powder raw materials + air" is directly transported, the "PowFilter Compact Model" is installed in parallel so that only the powder remains in the mixer after air treatment and dust collection.

Results of introduction

Shorten the mixing time of the noodle dough mixer

Since multiple powder ingredients can be mixed and supplied to the noodle mixer, kneading time is greatly reduced compared to adding a mixer for each type of powder. High-efficiency operation of the mixer was achieved.

Eliminates the worry of dust scattering

Dust scattering is a concern when powders are manually added. The introduction of the "PowFilter Compact Model" eliminates the leaking of powder from the noodle mixer, improving the yield of raw materials and the working environment.

A small rotation system

Since the work of putting the powder in the line from the raw material bag is done by hand, it is possible to premix by changing the recipe frequently, such as "flour ○ kg, auxiliary ingredient A ○ kg, auxiliary ingredient B ○ kg." This is a small rotation system for high-mix, low-volume production.