Case Studies

Case Examples

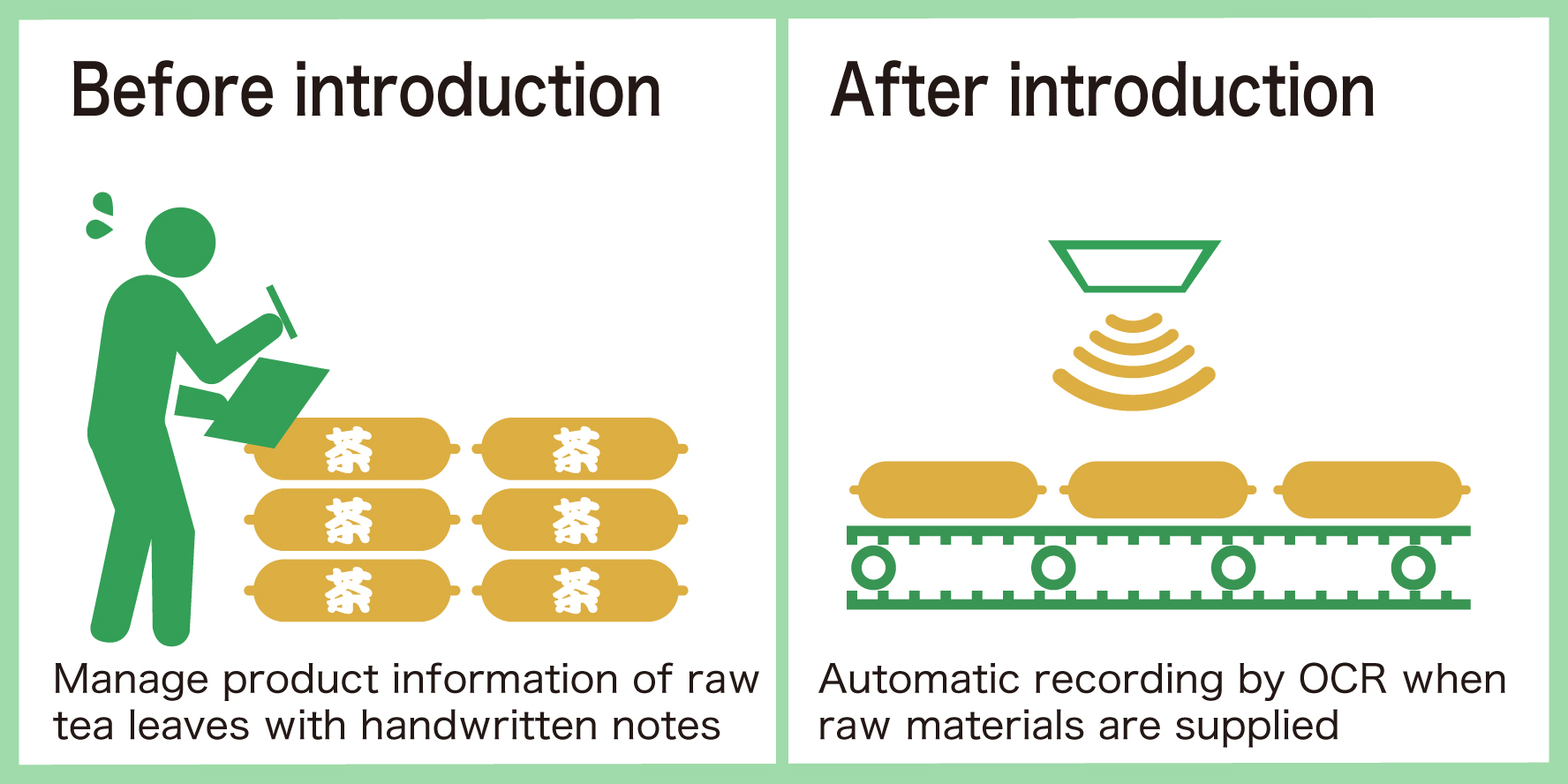

Labor-saving traceability of tea beverages using OCR

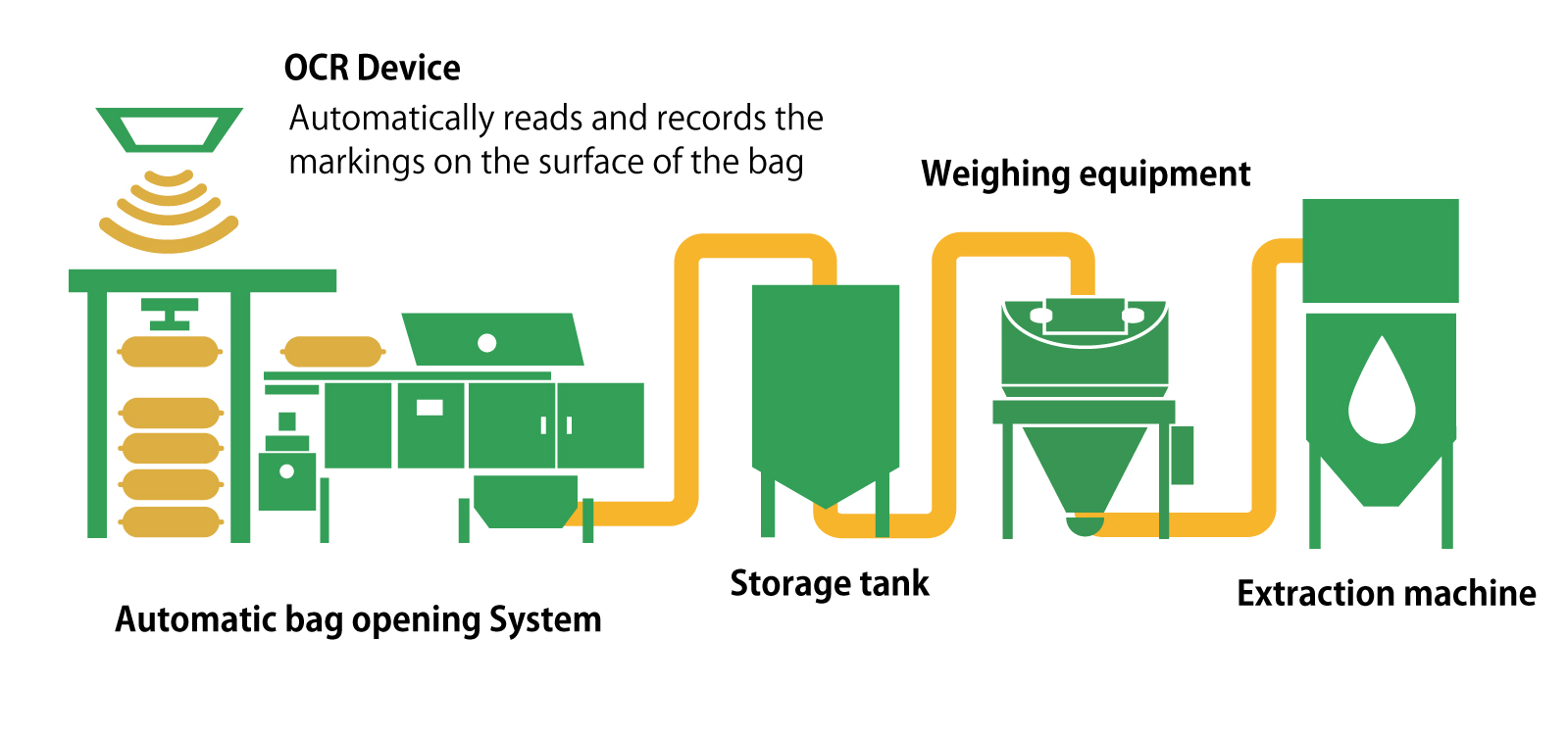

Material Receiving and Powder Feeding Process

Type of Industry

Soft drink manufacturer

Introduced Products

Automatic bag opening System, etc.

Background and problem

There are also challenges with heavy labor, the working environment, and removing foreign material

At one of our customer's factories, before storing raw tea leaves in paper bags in a storage tank, workers would handwrite (transcribe) and record the product lot and expiration date printed on the surface of the bag. Then, according to the recipe instructions, they weighed out each type of tea leaf and fed them into the extraction machine. This made the work extremely complicated, and there was always the risk of transcription errors.

In addition, carrying the raw material bags to the tank and feeding them in, as well as transporting the weighed tea leaf containers to the extraction machine, all had to be done manually, which created a significant workload.

In addition, carrying the raw material bags to the tank and feeding them in, as well as transporting the weighed tea leaf containers to the extraction machine, all had to be done manually, which created a significant workload.

TSUKASA Automated Line Construction Example

Automate the opening of raw material bags and read the printed information with OCR

Once the pallet of raw material bags is set into the automatic bag opening system, the process is fully automated up to the point where the bags are fed into the extraction machine. We proposed to automatically read the product lot and expiration date printed on the bag using OCR, eliminating the need for handwritten notes, and thereby significantly reducing labor and human error.

Additionally, we can flexibly configure production lines to suit the circumstances of the customer's factory!

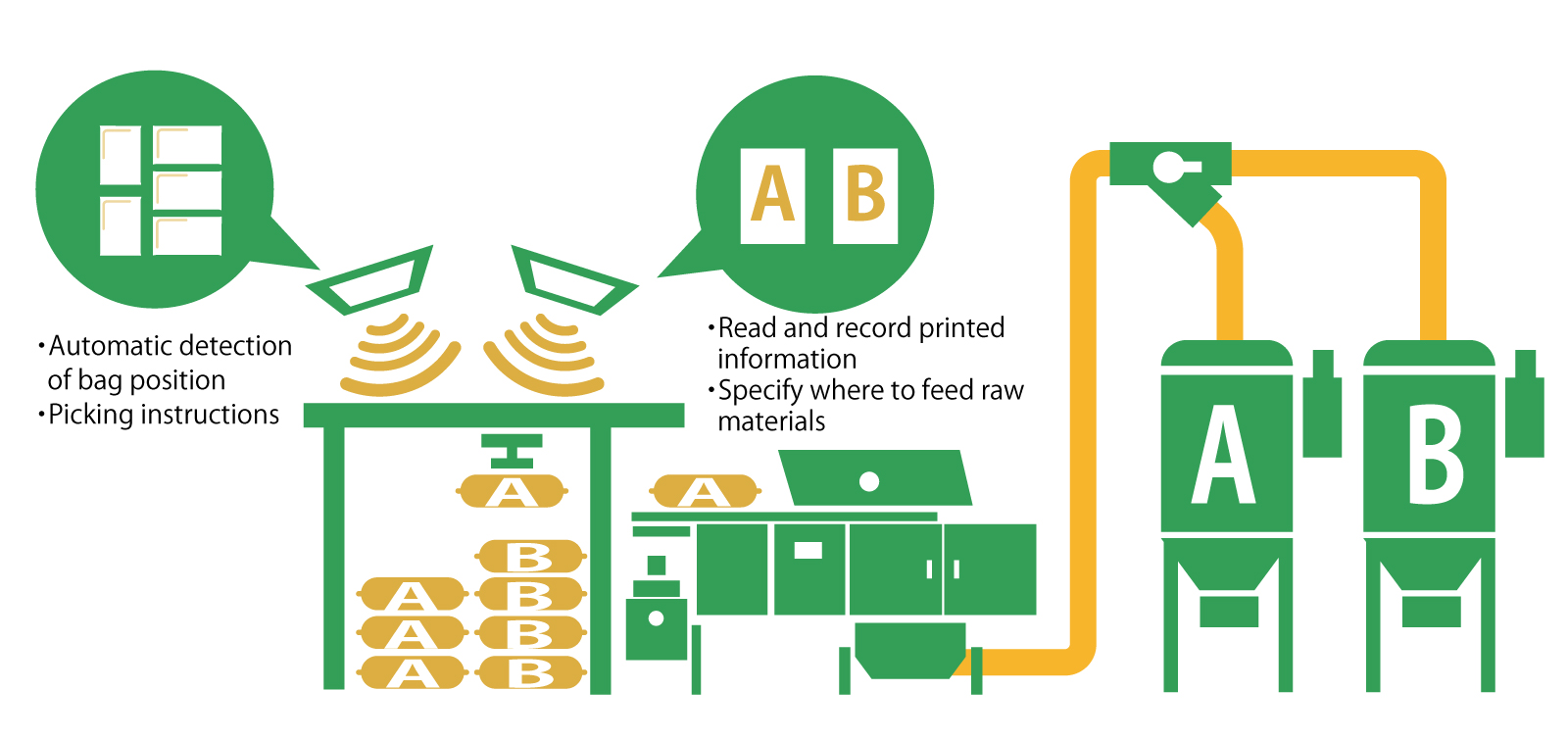

Overview of the TSUKASA OCR System

・Two cameras are installed on top of the bag-opening equipment

・Automatic detection of bag location and picking instructions

・Read and record information printed on the surface of the bag

・Specify where to feed raw materials (Tank A, B, etc.)

It is also possible to link with traceability systems that are already in operation.

・Automatic detection of bag location and picking instructions

・Read and record information printed on the surface of the bag

・Specify where to feed raw materials (Tank A, B, etc.)

It is also possible to link with traceability systems that are already in operation.

Message from TSUKASA

For those who are concerned about the condition of the product when raw tea leaves are transported by pneumatic conveyance

At TSUKASA, we have customers bring in the actual raw tea leaves to our in-house testing center, where we have created an environment where we can test what changes occur during pneumatic conveyance using actual equipment.

Please feel free to contact us.

Please feel free to contact us.